XYZ at MACH 2026: More than just machines

XYZ is set to make a strong statement at MACH 2026 (NEC Birmingham,20-24 April), showcasing the full breadth of its machine tool and control technology portfolio. From stand 20-160, the company will demonstrate how its offering goes beyond individual machines to deliver flexible, productivity-focused manufacturing solutions.

A central theme of the display will be the growing demand for adaptable machining platforms that support both traditional toolroom work and more advanced, automated production. XYZ will illustrate this trend with a cross-section of machines, from entry-level CNC systems to multi-axis machining centres and Siemens-controlled turning platforms.

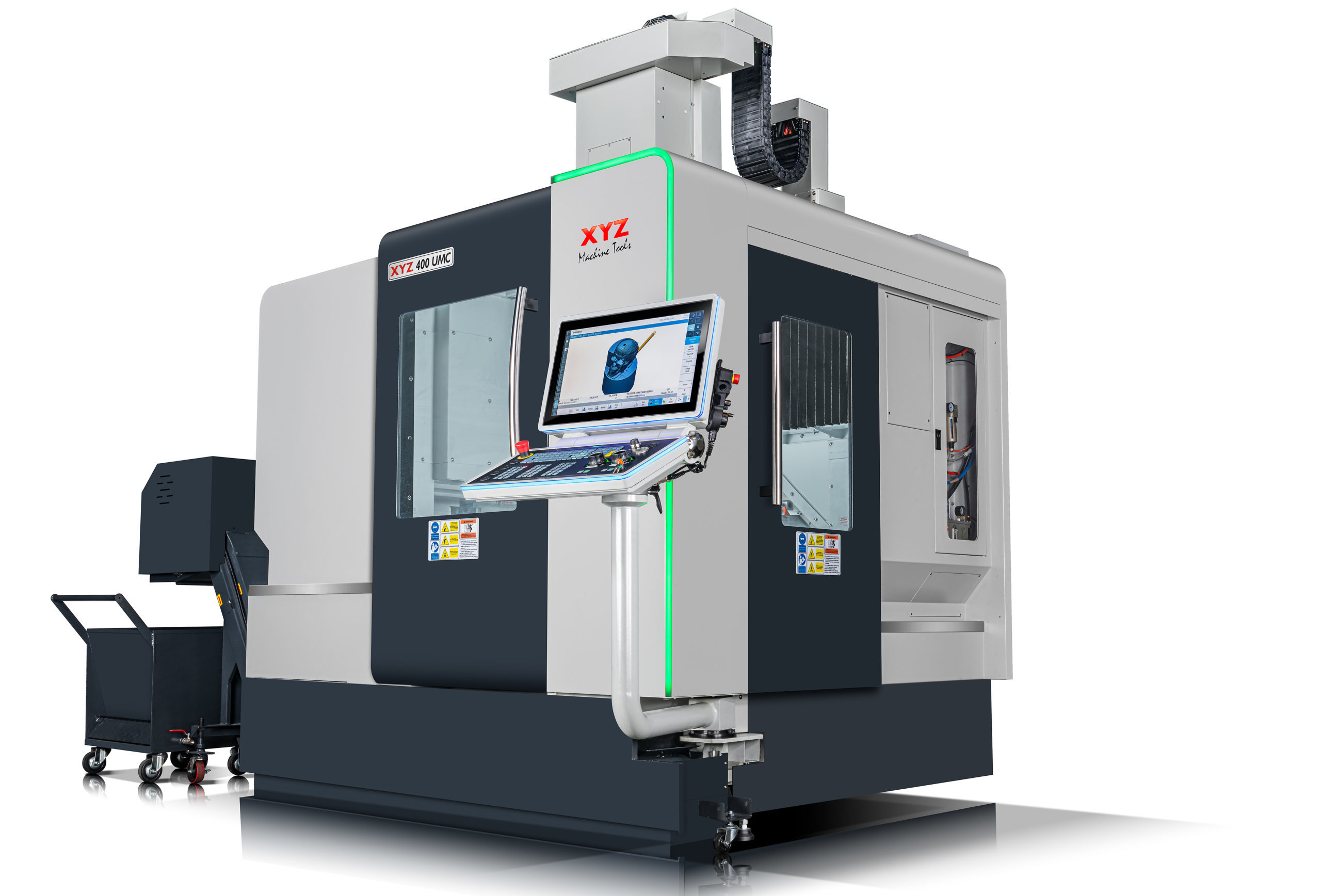

Among the highlights is the 400 UMC universal milling machine, available in 4+1 or full five-axis configurations. Designed to reduce set-up times while enabling complex component geometries, it reflects demand for compact machines with higher capability. Visitors will see it equipped with a 400 mm tilt/rotary table, BBT40 spindle rated at 35 hp and software options that allow five-axis functionality to evolve with production needs.

For those entering CNC machining, the KMX 2500 bed mill offers a user-friendly route. Its simplified control interface and compact size make it ideal for workshops transitioning from manual machining, while maintaining ease of use. Alongside this, XYZ will showcase established toolroom machines, as well as platforms capable of integrating modern tooling and automation solutions.

MACH 2026 will also highlight the evolution of XYZ’s control technology over more than three decades. The ProtoTRAK control of the 1990s has developed into today’s KMX, RLX and RMX families. KMX controls, demonstrated on the KMX2000 and KMX2500, are suitable for prismatic parts and entry-level CNC machining. RLX and RMX touchscreen controls, featured on ProTURN lathes, bed mills and toolroom centres, allow manual or conversational CNC programming for one-off and small-batch production.

XYZ’s TMC (Toolroom Machining Centre) range demonstrates the move toward automation. Integrating RMX controls with compact machining platforms, the 750 TMC and 1600 TMC offer rapid programming, automatic tool changing and unattended machining, alongside optional features like through-spindle coolant, fourth-axis capability and swarf conveyors.

Siemens-controlled machines, including the CT52LR and 65LTY-S lathes, plus the 500LR and 800HD vertical machining centres, showcase alternative constructions, spindle power options and advanced turning capabilities, from two axis to Y axis with sub spindles for complex, single set-up parts.

Beyond hardware, XYZ will highlight lifecycle support, focusing on maximising uptime, extending spindle life and optimising long-term performance.