WorkSport reshores US production with Prima Power’s PSBB line

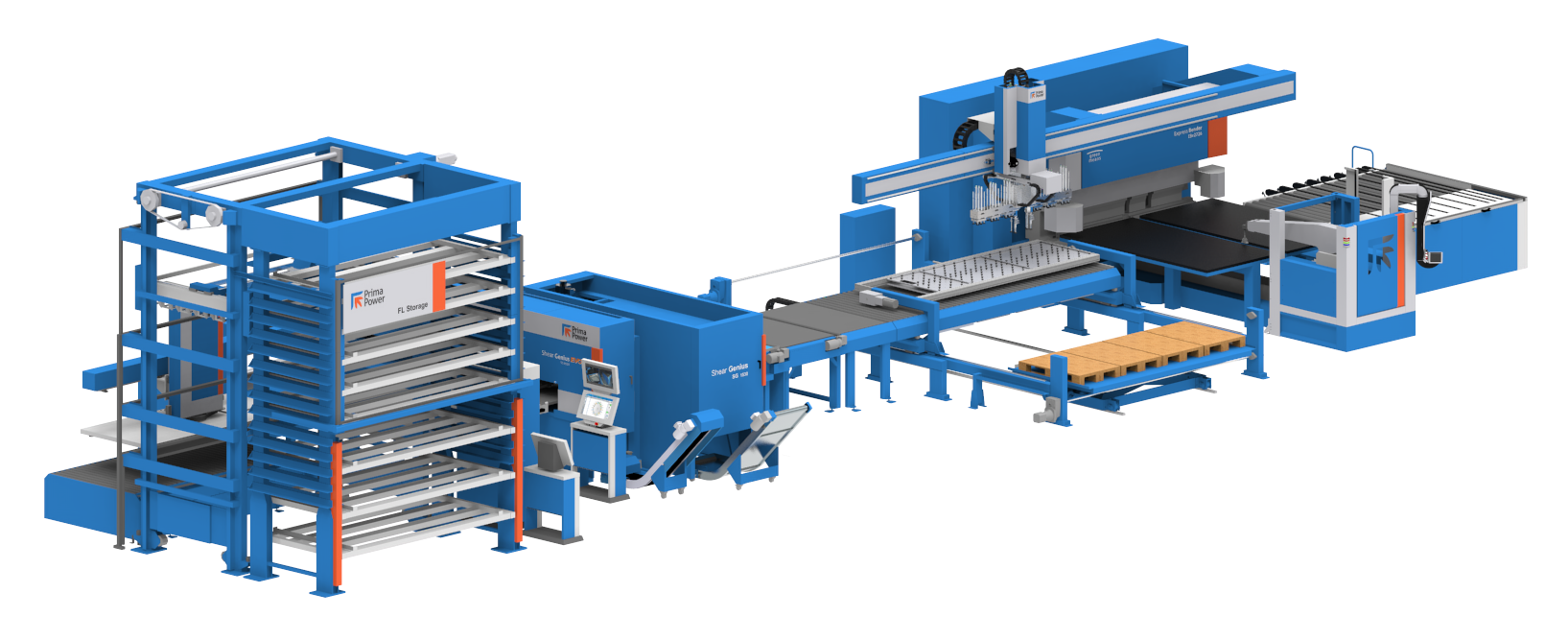

With full control of its US facility, Worksport has boosted efficiency, improved product quality and expanded its ability to build advanced truck covers and clean energy solutions at scale. In an era where nearshoring is more than a trend – it’s a necessity – Worksport is proving that American manufacturing innovation is alive and well. Known for its disruptive approach to truck bed cover systems, tonneau covers, and its energy-forward products like SOLIS and COR, Worksport recently took a bold step: bringing manufacturing in-house. With automation at the core of this strategy, the company turned to Prima Power and its PSBB (Punching + Shearing + Buffering + Bending) line.

Bringing manufacturing home

Based in Buffalo, New York, Worksport builds smart solutions for truck owners, from bed covers to portable solar systems. After initially planning to scale production overseas, the company made a pivotal decision: to bring manufacturing in-house and take full ownership of how its products are made. The shift wasn’t just about cost, it was about control, quality, speed and vision. And that vision started with a challenge: how to produce better covers, closer to home and with long-term scalability in mind.

“Originally, we were going to grow manufacturing in China,” says COO Chris Bernaudo. “Then we raised triple what we expected and everything changed. We shut the curtains, built a new type of company and brought it all home.”

Why Worksport turned to Prima Power

The company’s West Seneca, NY facility wasn’t just built, it was reimagined from the ground up.

“We wanted to automate as much as possible from day one,” explains Chris. “Not to eliminate people, but to eliminate human error. It’s about consistency and quality.”

That philosophy led the company to Prima Power’s PSBB line.

“We weren’t looking for manual benders. We had a design in mind and sought the best solution. Other suppliers offered cells, we needed a full line. Prima Power was the only one that came close.”

Beyond technical capability, support played a major role.

“Prima Power’s responsiveness and service really sealed it for us,” says Fred Winter, lead PSBB operator. “Any time we’ve had issues, the team is right there with us. The support and training have been top-notch.”

Integration that delivers results

Installed and operational within a year, the PSBB line now acts as the ‘heartbeat’ of the facility.

“We can run coil to panel in under five minutes,” says Fred. “It’s incredibly efficient, especially with over 90 different products requiring custom lengths.”

That speed translates into strategic agility.

“Our operation is basically built around the Prima Power cycle time. It sets the pace for everything.

The integration hasn’t just improved throughput. Worksport has reduced material waste, enhanced quality and gained confidence in repeatability.

“We even modified some parts of the machine to handle our delicate painted material,” reveals Fred. “Now it runs clean, consistently – even overnight.”

Empowering the workforce through technology

Despite being built around automation, Worksport’s culture is anything but cold.

“The goal was never to replace people,” says Chris. “Automation releases them to focus on higher-value tasks, and that builds pride.”

Fred, who joined the company when it had just four employees, agrees: “This machine made me love sheet metal. We’ve got the Ferrari of machines here.”

From training to troubleshooting, the Prima Power system has empowered the team to learn and grow.

“We’ve dealt with every kind of issue-sensor problems, encoder cables, you name it,” says Fred. “Now we feel confident. The Prima Power team helped us learn and adapt every step of the way.”

Built in America, ready for anywhere

With operations growing and hiring ramping up (from 60 to over 120 by year-end), Worksport is executing a clear vision.

“We’re growing aggressively, but not impatiently,” says Chris. “We’re doing it step by step.”

That includes elevating truck bed covers to a new standard.

“Our competitors have lowered quality. We saw that and knew we could do better.”

Worksport’s products are built with the end user in mind-from thicker aluminium panels to smart, functional designs that hold up over time. And it’s all made in The US, something investors, customers and employees can rally around.

Says Chris: “This facility used to be a beer distribution centre. Now it’s where we make the most advanced truck bed covers and power systems in the market.”

The future? Covered

WorkSport isn’t stopping at covers.

“We’re building a full power ecosystem,” explains Chris. “The truck cover is just the start. Our solar-integrated cover and modular battery system open the door to adventure, independence, and energy freedom.”

From off-grid film crews to weekend overlanders, Worksport sees its future in powering mobile life-built on the backbone of rugged, intelligently designed truck accessories.

“It’s not just about trucks. It’s about what trucks enable. We’re giving our customers the tools to go further and do more.”

At the centre of that journey is a bold investment in manufacturing and a technology partner in Prima Power.

“We bring people through the factory and they stop at the PSBB,” concludes Fred. “It’s the showpiece. It’s the proof that we’re serious.”