Walter presents latest ConeFit Milling cutters

With the upgrade of its ConeFit milling cutters, Walter is presenting the latest version of the company’s interchangeable head system. Now, 17 milling cutter families have been merged into eight and provided with new ordering codes adapted to the current nomenclature.

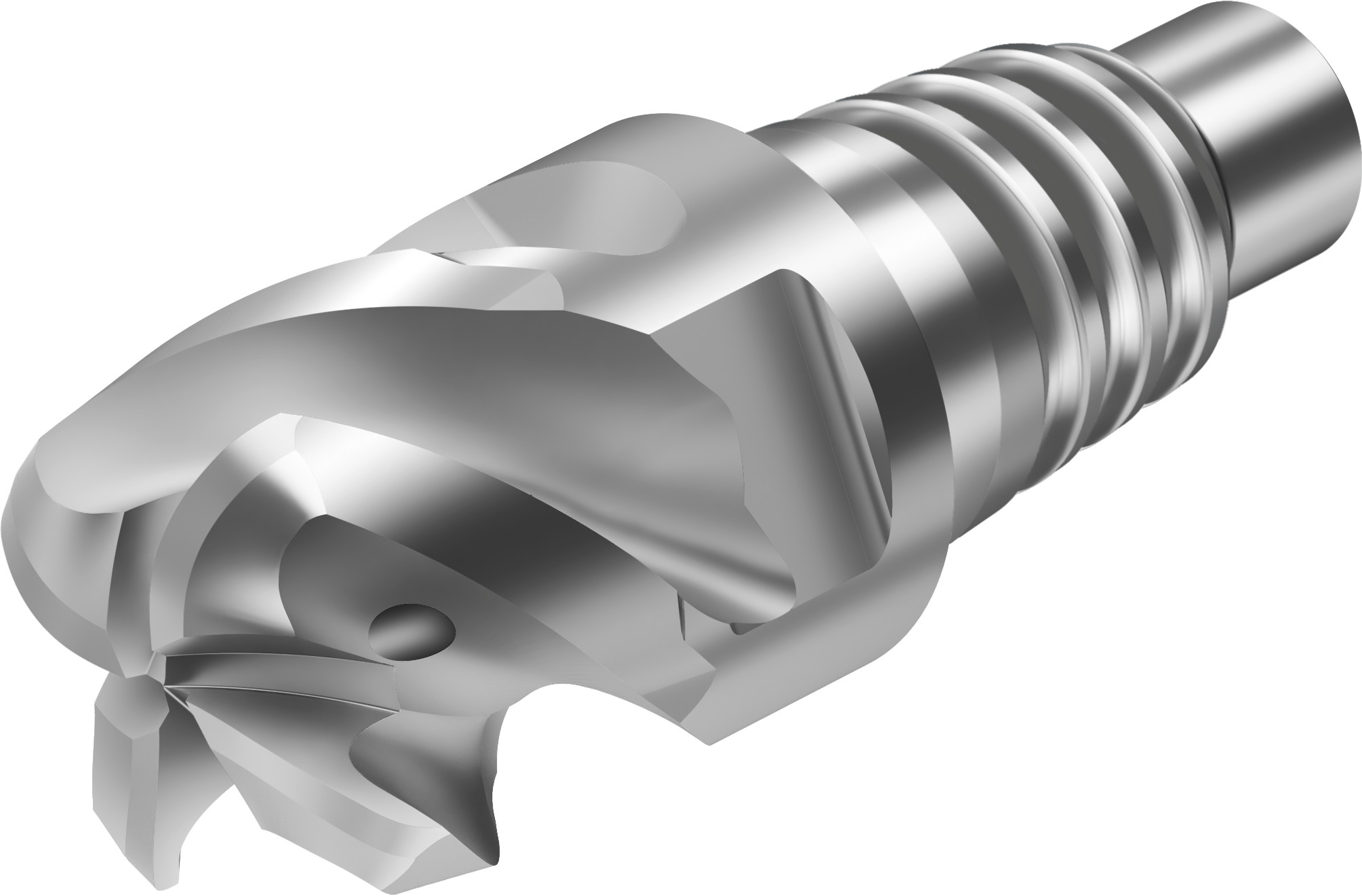

For customers, the move means simplified order handling. At the same time, applications benefit from a technical upgrade thanks to the newly added coating with the wear-resistant WJ30TP grade from Walter. The universal TiAlN coating with a gold-coloured ZrN top layer not only extends tool life, it also allows rapid wear detection. Like all ConeFit replaceable heads, the enhanced milling cutters are also characterised by their precision and self-centring interface that consists of a thread, cone and contact surface. This design enables tool changes with speed, accuarcy and stability.

As a technical highlight, the MD340 ConeFit Milling cutter is a specialist for ISO P materials. Its variable 39°/41° helix reduces vibration, which increases operational smoothness, performance, surface finish and tool life. The z4 milling cutter is available in a diameter range from 10 to 20 mm, with or without a corner radius.

The MC430 and MC500 also both incorporate the WJ30TP grade. Additionally, the internally cooled MD070 has also been WJ30RA coated. This revised Walter ConeFit programme also includes other milling cutters upgrades.

The wide selection of high-performance, re-grindable milling heads is complemented by their flexibility, reports Walter, with the ability to utilise different milling heads in one adaptor. Milling cutters can be changed in seconds without re-tooling or resetting and with minimal downtime.