Walter launches two new grooving geometries

With the arrival of the new UE6 and RE6, Walter is expanding its GD26 grooving portfolio with two indexable insert geometries for medium machining. The Germany-based cutting tool manufacturer now offers a total of 12 geometries in seven wear-resistant Tiger-tec Gold grades for parting-off, grooving, groove-turning and copy turning.

According to Walter, the new UE6 geometry is characterised by its ability to generate low cutting forces and effective chip control, particularly when grooving and groove-turning. Alongside the UE6 is the new RE6 full-radius range of inserts which Walter says has been designed to generate excellent surface finishes and optimum chip control, especially when undertaking dynamic turning.

Thanks to its large chip-breaking range, UE6 geometry enables reliable chip evacuation in all grooving operations. Complementing this capability, RE6 geometry offers the best conditions for copy and relief turning. Both variants are suitable for use with the Groov-tec GD grooving system, the stability of which further enhances the potential of the inserts.

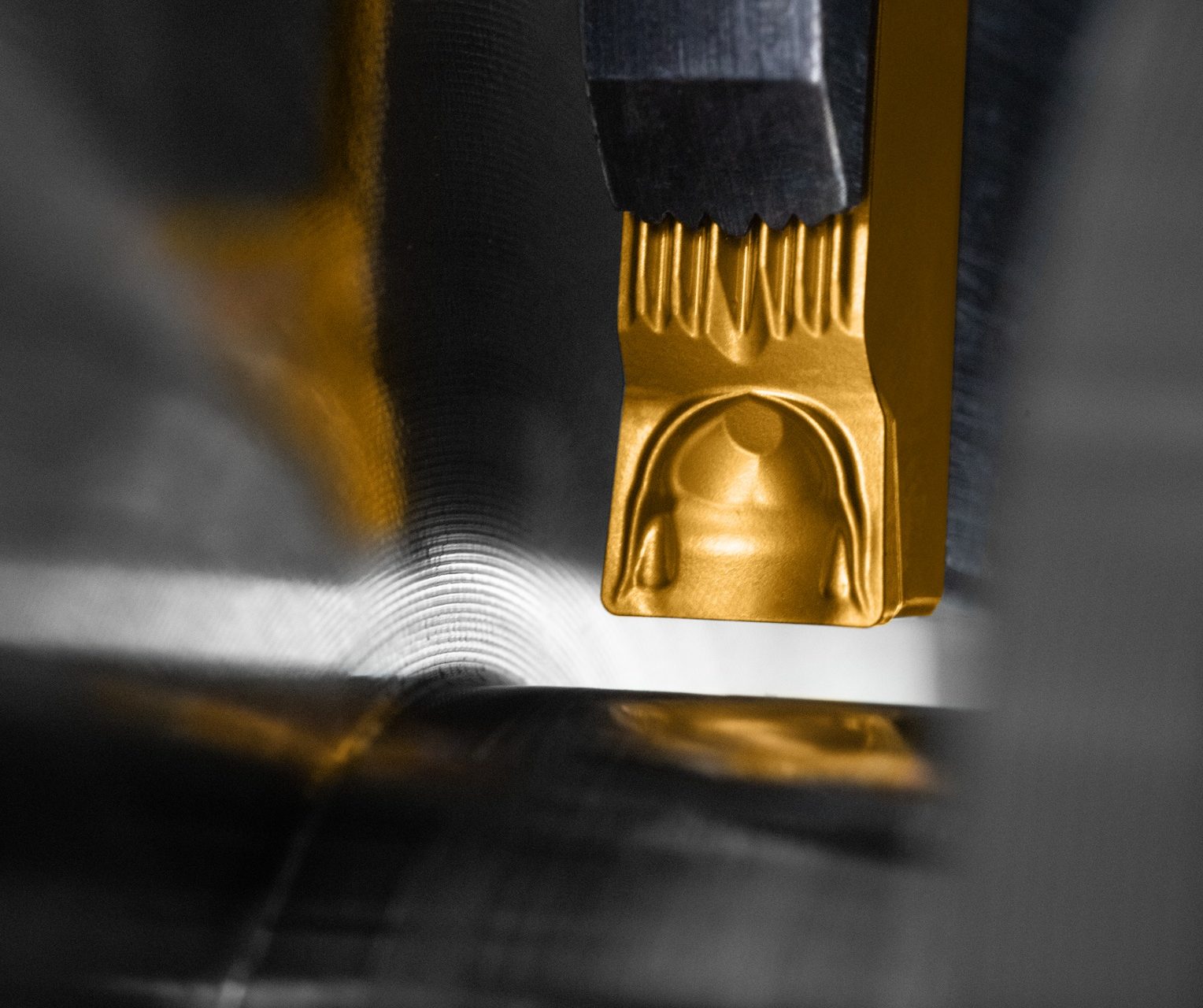

Fitted with Tiger-tec Gold Indexable inserts, the Groov-tec GD can be used universally for all ISO material groups. The patent-pending double serration profile is central to the high stability of the system. It prevents the cutting insert from being pushed out of the insert seat from the side. A raised centre tooth serration also secures the insert against incorrect engagement into the pocket.

In addition to the increased stability compared with standard prism clamps, the serrations on the Groov-tec system minimise wear and dampen micro-vibrations during the cut. This capability increases tool life by up to 50%. When combined with the optional precision cooling system, machining applications can benefit from shorter cycle times, higher productivity levels and improved process reliability, reports Walter. In addition to the advantages gained during demanding machining operations, Groov-tec GD offers conditions conducive to unmanned and high-volume production.