Walter completes Perform line with addition of new milling cutters

Walter has completed its Perform line with the addition of new five and six-flute solid-carbide milling cutters for the ME232 Perform series. The company has also added two- and four-flute ball-nose end mills to its ME432 Perform series.

The Perform line offers advantages to machine shops that work with small and medium batch sizes whereby users are often not able to maximise the tool life of a high-volume tool. At the same time, manufacturers in price-conscious segments also stand to benefit. According to Walter, the new, short three- and four-flute cutting tools for turning centres with stationary or driven tools offer huge potential as they are part of the standard set-up in this field.

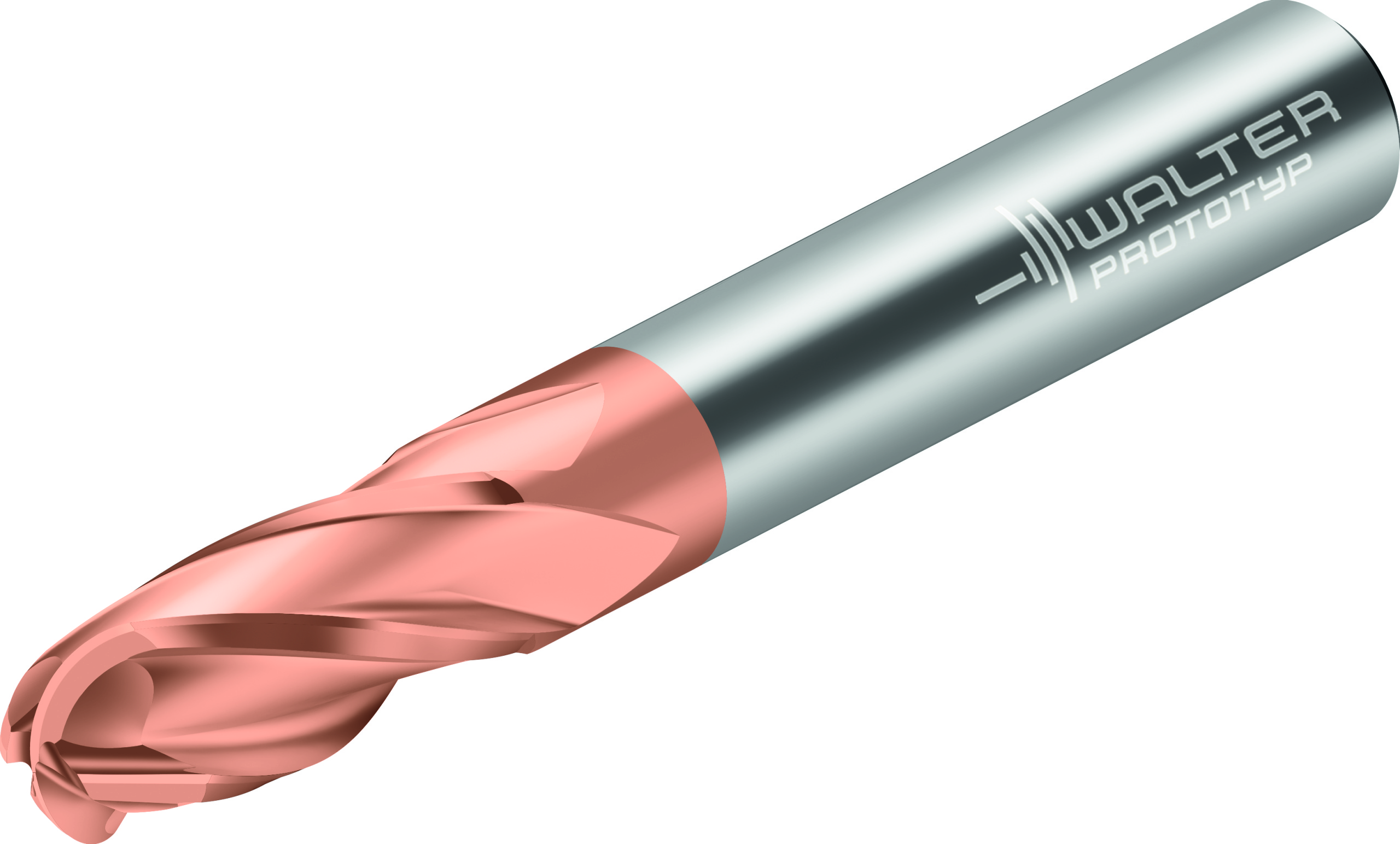

With the latest additions to its product range, Walter now offers the Perform line of milling cutters with diameters from 1 to 20 mm, two to six cutting edges, and cutting edge lengths from 1xDc to 3xDc. The new Perform line of milling cutters incorporates a ‘high-performance geometry’, meaning that the number of teeth and helical pitch co-ordinate to ensure operational smoothness and high material removal capacity.

Another factor they have in common is their cost-efficiency and universal application for many different materials and milling strategies. Furthermore, despite offering value for money, Perform line users enjoy the same support services that are typical of Walter’s higher end tools. Alongside STEP files and data models for programming, these services include calculating and providing cutting data with the Walter GPS ‘machining navigation system’.