Vericut Optimizer proven to reduce energy during machining

While is straightforward to demonstrate the cycle time reductions facilitated by Vericut Optimizer, substantiating claims regarding the energy savings of this innovative software has proved more challenging. Now, however, an independent energy monitoring trial involving Seco Tools, Virtual Manufacturing UK and Grob, confirmed that the estimated 19% savings in electricity consumption when applying Optimizer to a sample titanium workpiece did indeed correlate to actual measured data.

With Vericut Optimizer, a stand-alone version of Vericut’s integrated Force module, the company can easily prove facts and figures regarding cycle time savings to its customers and prospects. Vericut simply takes an existing process and applies Optimizer to get a ‘before and after’ result.

The company also knows that the impact of this optimisation means the CNC machine consumes less energy. This fact was recognised recently, with Vericut and Seco Tools winning the prestigious 2025 ‘Sandvik Sustainability Award in Memory of Sigrid Göransson’. The accolade recognised a collaboration that continues to provide a significant contribution to reduced environmental impact during machining. In tests, Vericut Optimizer reduced machine energy consumption by 18% and demonstrated a substantial increase in tool life.

“Having won the award, we wanted to back-up calculated savings with hard evidence of the energy savings that Optimizer provides,” explains Scott Ravenscroft, Sales Manager at Vericut UK. “We asked Seco Tools to produce a sample component on its Grob 550T universal CNC mill-turn centre and invited Virtual Manufacturing UK to monitor the machine’s energy consumption in real time.”

Adds David Magnall, Innovation Partnership Manager at Seco Tools UK: “Our Innovation Hub at Alcester is where we assess factors beyond just cutting tools. We look at more holistic solutions for customers, perhaps involving digitalisation or sustainability, for example. All projects take place in collaboration with technical partners, in this case Vericut, Virtual Manufacturing UK and Grob.”

Sustainability is a hot topic right now and something that manufacturers increasingly consider as part of their investment strategies. It can even influence funding decisions if the technology solution identified is particularly energy efficient.

“If we can offer sustainable, holistic solutions, the impact on the manufacturing industry will be positive and profound for all stakeholders: technology suppliers, users and funders,” says David.

Knowledge is power

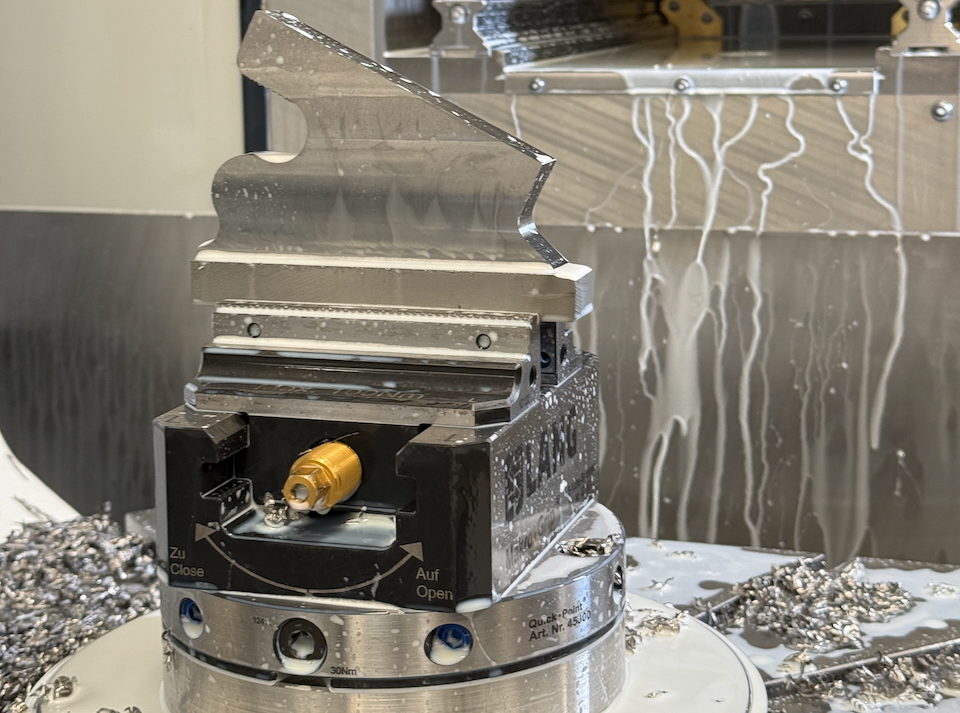

The trial focused on the machining of a titanium (Ti-6Al-4V) sample workpiece featuring a number of freeform surfaces, pockets and slots. Recording an original (unoptimised) cycle time of 30 minutes and 35 seconds, a second run following the application of Vericut Optimizer saw this time reduce to 23 minutes and 6 seconds, a 24.5% saving. The various operations included dynamic milling, face milling and radius cutting using a selection of Seco cutters, such as solid-carbide end mills and indexable-insert shoulder mills.

Then it was time to re-run the trial with energy monitoring hardware, including current clamps and a sender unit, temporarily fitted to the three-phase, 440V main feed of the Grob CNC mill-turn machine. The system was able to collect, process and report total energy consumption for both optimised and non-optimised NC code.

“For the purposes of trial expediency, data analysis took place manually using spreadsheets,” says Henrik Nyby, Manufacturing Consultant at Virtual Manufacturing UK. “Virtual Manufacturing UK specialises in real-time energy monitoring and digital optimisation tools for manufacturers, with Gazpacho Energy at the heart of our offering. By continuously monitoring energy usage, Gazpacho Energy enables you to make informed decisions on when and how to deploy your production equipment. You can uncover patterns, identify peak usage times, pinpoint energy inefficiencies, and optimise your operations for maximum efficiency.”

19% energy savings

Algorithm-based Vericut Optimizer data showed predicted energy savings for the component of 19%. With Virtual Manufacturing UK’s help, the aim was to qualify this calculation.

“Capturing and collating data across the main feed showed the Grob machine consumed 13.75 kWh for the un-optimised cycle of the titanium sample component, whereas the optimised cycle saw the machine consume 11.11 kWh: a 19.2% reduction,” reports Henrik.

Adds Luke Manders, Development Engineer at Seco Tools UK: “Interestingly, certain machining strategies, such as adaptive milling, appeared to deliver higher energy savings than other operations. The trial proved useful in many ways, helping to grow our knowledge of this technology.”

A reduction in electricity usage of around 19% is significant and would accumulate rapidly over a batch of components.

“The energy savings add to the already considerable savings that Vericut Optimizer provides in reduced cycle times, typically 10-30%, making for an attractive investment proposition with a potentially fast return-on-investment,” says Scott.

Most CAM systems do not adjust for changing cutting conditions. In particular, they fail to compensate for chip thinning. Chip thickness is the most important parameter when machining, not feeds and speeds, as many assume. Vericut Optimizer automatically adjusts chip thickness for each tool operation using Vericut-calibrated materials and cut-by-cut tool engagement analysis. Optimizer keeps the chip thickness as constant as possible by adjusting feed rates, block by block of NC code, even adding blocks if necessary to deliver ideal cutting. The result? Shorter cycle times.

Life support

Another aspect of the sustainability trial at Seco Tools was tool life and the potential provided by Vericut Optimizer to extend the lifecycle of carbide tools. Optimizer provides a balance between machining with high cutter engagement (for productivity) and the prevention where necessary of excesses like force, deflection and chatter to reduce carbide shocks and extend tool life. Unfortunately, the trial at Seco Tools did not demonstrate sufficient run time to verify extended tool life of up to 30% witnessed by Vericut on other customer parts.

With the trial complete, the next step will see Seco Tools UK extend the sustainability theme at its ITI (Inspiration Through Innovation) event in February 2026.

“We’re working towards the creation of an entire end-to-end sustainability demonstrator,” reveals David. “By considering the manufacture of a component from start to finish, we plan to show how many process touch points we can impact in terms of sustainability. In total, the demonstrator will involve solutions from around 12 technology partners, with Vericut Optimizer playing a central role. The event will also feature an expert panel discussion on this increasingly important topic.”