Total integration in sheet metal processing: Prima Power at Blechexpo 2025

Prima Power, a specialist in technology integration in the sheet metal working industry, showcased the power of total integration at the recent Blechexpo 2025 exhibition in Stuttgart, Germany. Under the motto ‘Evolve by integration’, the company presented its latest modular, scalable and automated solutions designed to grow with the evolving needs of modern manufacturers.

World premiere: Express Robot Cell

Among the key highlights of the stand was the Express Robot Cell, a new compact robotic bending cell making its world premiere. This flexible and fully automated solution integrates an eP0520 servo-electric press brake with 50 tonne of bending force and a 2320 mm bending length, a six-axis anthropomorphic robot and a three-axis Cartesian loader in a reduced footprint, making the cell suitable even for space-constrained environments. Its compact layout allows for fast movement execution and low cycle times, resulting in high productivity. The two robots work in parallel, further enhancing system efficiency.

The Express Robot Cell is designed for maximum flexibility and can handle a wide variety of part geometries with just two universal grippers equipped with suction, magnetic and clamping technologies, as well as one automatic tool-changing gripper. The entire cycle – gripping, centering, bending, overturning and unloading – is autonomously managed for optimal efficiency.

According to Prima Power, what truly sets this solution apart is its connectivity and expandability. Express Robot Cell can be integrated with FMS storages, such as the company’s Power’s Night Train, enabling continuous, unattended production. The stand-alone version can be easily upgraded to a connected solution, with automated loading from storage systems and unloading to automated guided vehicles (AGVs).

The system is built on a plug-and-play integrated metallic platform that houses the press brake and robot with peripherals in two main components, ensuring fast transport and easy installation. It is suitable for sectors like home appliance, HVAC, automotive, metal furniture and industrial components, handling small- to medium-sized parts from simple to highly complex geometries. Leveraging the know-how of the Prima Power Robotics Integration Unit, the new system is designed to grow with the customer from a stand-alone unit to a fully connected production cell.

Integrated productivity: Combi Genius with LSR

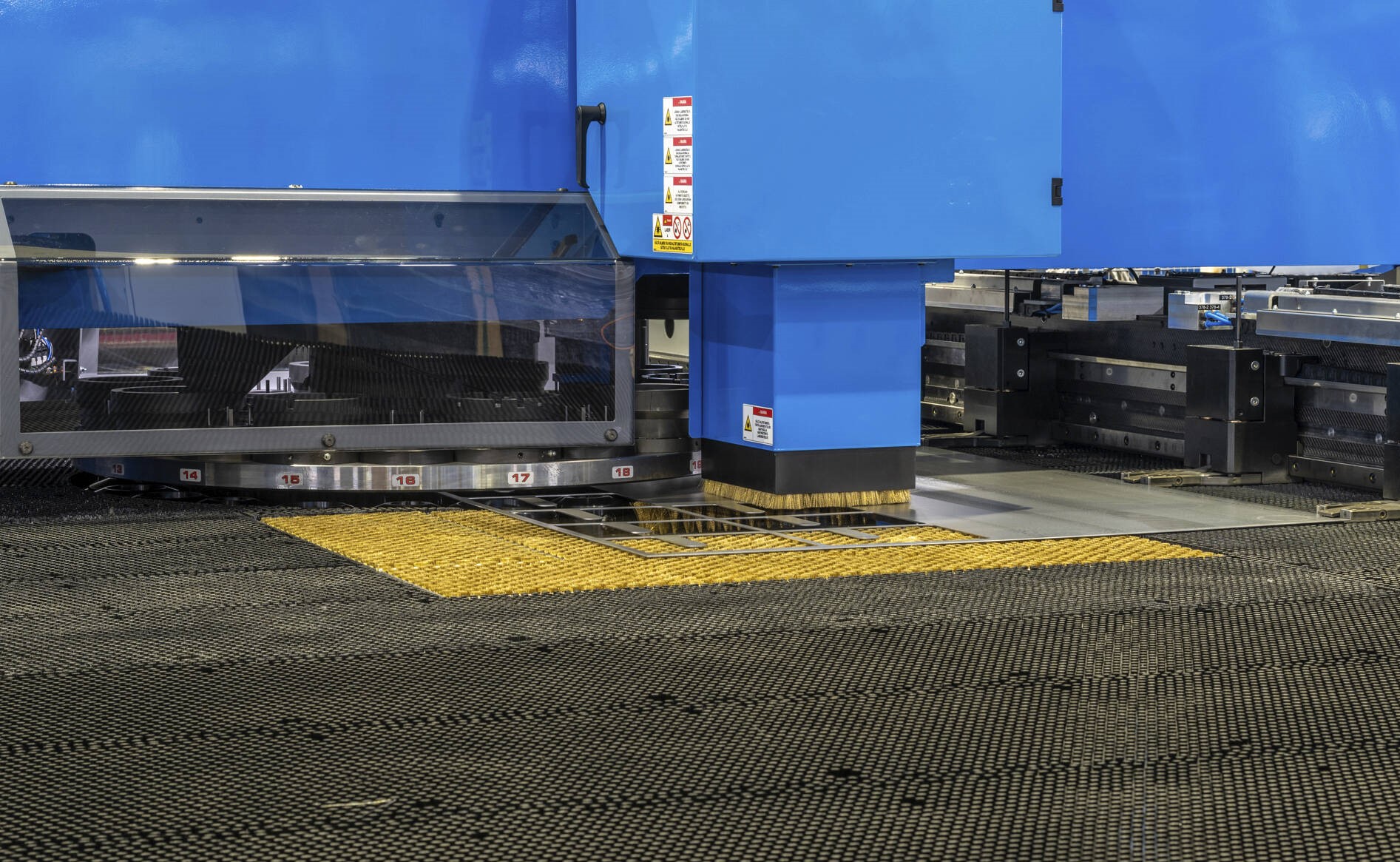

Also on display was the Combi Genius punch-laser combined system, a reference point for versatility and productivity in advanced manufacturing. This modular solution merges punching and laser cutting in a single machine and, when combined with the LSR (Loading and Stacking Robot), becomes a fully automated system for sheet handling, part picking and intelligent stacking.

Combi Genius integrates multiple processes – punching, tapping, forming, marking and laser cutting – into one highly efficient cell. Thanks to its intelligent brush table system, it can handle even the most complex shapes and sensitive materials across a wide material range from 0.5 to 8 mm. With up to 400 tools in turret, a 6 kW fiber laser, and performance levels reaching 300 kN punching force and 1000 hits per minute, Prima Power says it delivers best-in-class productivity without compromising flexibility.

When connected to systems like Night Train FMS or integrated with a panel bending machine, Combi Genius becomes the core of a complete flexible manufacturing system (FMS), enabling end-to-end process automation with minimal manual intervention.

One suite, all technologies: Prima Power’s integrated approach

At Blechexpo, Prima Power displayed its fully integrated software suite NC Express CAM and its expanded capabilities. A key highlight is the new NC Express Brake, which enables programming the entire eP series servo-electric press brakes.

The integration of technologies – from laser cutting, punch-shear and combi to panel benders and press brakes – unlocks the full potential of a connected workflow. One of the most powerful advantages is the automatic propagation of design changes across all stages of programming, regardless of the technology involved. This reduces programming time while ensuring consistency and efficiency across the production process. These advancements reaffirm Prima Power’s commitment to delivering an intelligent, user-friendly, all-in-one software ecosystem that empowers manufacturers to optimise their operations through smarter, faster and more connected workflows.

Prima Power’s breakthroughs in 3D laser processing

In addition to the products on display, Blechexpo gave visitors an exclusive look at Prima Power’s latest innovations in 3D laser technology. Among the highlights was the recently launched Giga Laser Next, designed as a game changer for high-volume automotive production.

Giga Laser Nex features a market-first configuration with four heads working simultaneously on a single piece that boosts productivity by 280% per square metre.

Making its debut at Blechexpo, the Laser Next Core 2131 builds on the Laser Next platform to deliver quick payback and reduced total cost of ownership. Engineered specifically for job shops, Prima Power says it offers the largest working envelope in its category and high levels of versatility for both 2D and 3D cutting and welding, plus one-click programming for rapid CAD-to-cut transitions.