Tool Manufacturing Around The Clock

Based in Lower Bavaria, Huber GmbH CNC-Präzisions-Werkzeugschleiferei has for 30 years been a medium-sized company repairing and manufacturing precision tools for the machining industry. The Eggenfelden company also develops and produces high-quality special tools, circular saws and band saws.

The VOLLMER Group’s sharpening machines have been part of the Huber machine park from the very beginning, and last year they completed their ensemble with a VGrind 360S grinding machine. Huber is using the VOLLMER machine and its 24/7 automation capability to boost the production of semi-standardised milling tools for the machining industry.

“We have come a long way since the foundation of our company in 1994, and we are now a strong German company with 30 highly motivated employees,” says Andreas Fröhlich, Operations Manager at Huber GmbH. “We must set a good example in the tool manufacturing industry in terms of quality, customer focus and employee satisfaction.”

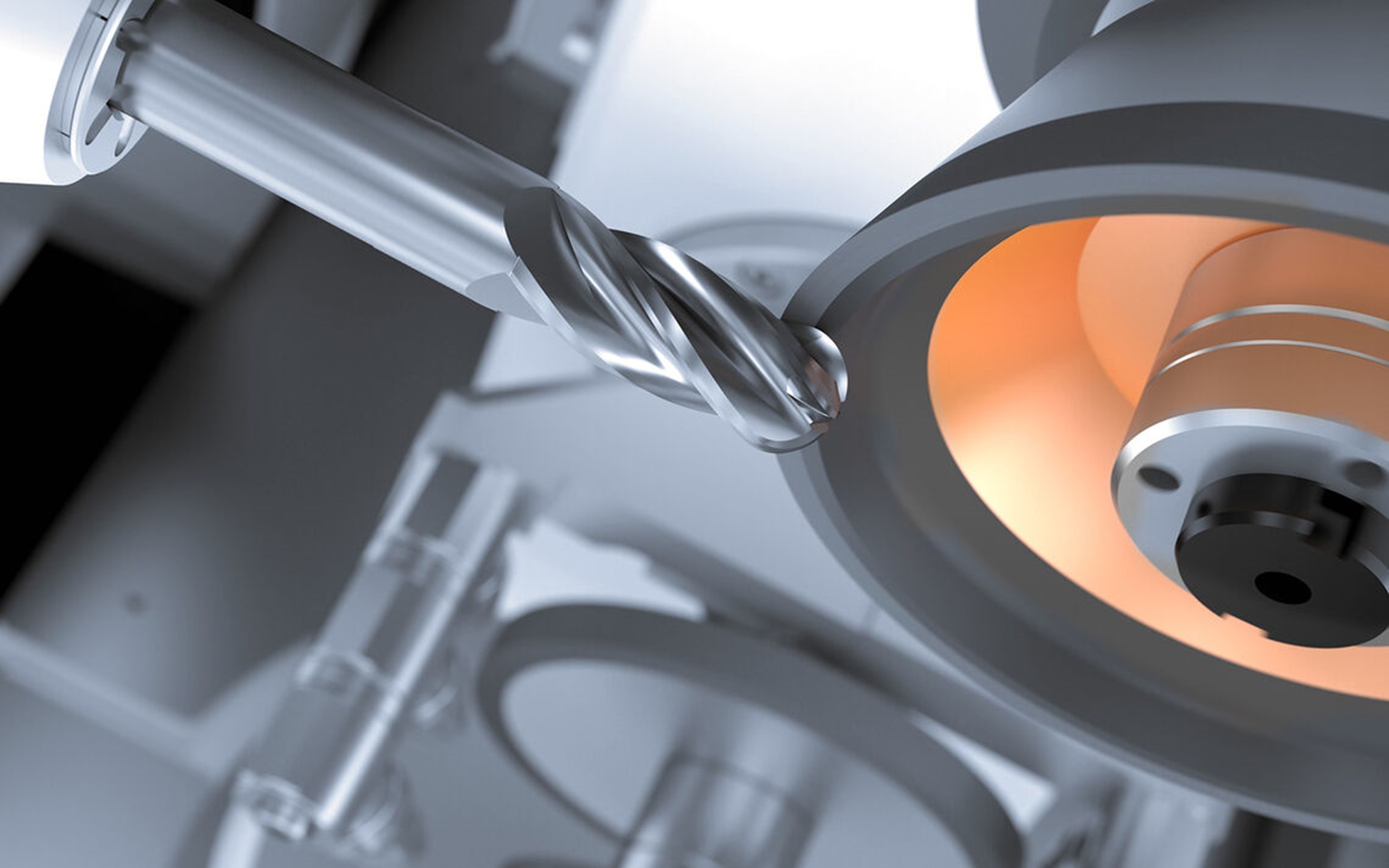

Manufacturing high-quality, durable and cost-effective standard and special tools, resharpening circular and band saws as well as knives and reliably supporting customers with services – this is how Huber GmbH has made a name for itself in the industry. Its range of carbide tools includes high-performance milling cutters such as end mills, radius and ball end mills, torus cutters, special milling cutters and mould tools. It also offers personalised advice and services such as a coating service. By coating its tools with temperature-resistant and wear-resistant auxiliary materials, Huber ensures significant improvements in carbide tools’ operating life and cutting performance.

“When it comes to sharpening machines, we have relied on the technological expertise of the VOLLMER Group since our company was founded. We currently have five VOLLMER machines in use – our most recent purchase was a VGrind 360S last year,” says Andreas Fröhlich

Huber uses the VOLLMER CHD 270 machine and the Solution K850-T and KBN710 sharpening machines from Loroch – a company of the VOLLMER Group to machine carbide-tipped and high-speed steel circular saws. Thanks to automation solutions, the machines typically run around the clock, grinding carbide-tipped circular saws with diameters of up to 840mm. To meet the increasing demand for high-performance carbide milling cutters, Huber purchased a new VOLLMER VGrind 360S tool grinding machine in 2023. This investment has enabled Huber to expand the production of standardised cutting tools. Equipped with the VOLLMER HC4 chain magazine, up to 158 shank tools with different sizes and geometries can be automatically produced and machined.

“The VGrind 360S grinding machine with chain loader enables production around the clock, seven days a week, allowing us to fulfil our high order volume quickly and with high quality and precision. As such, the VOLLMER machine is a perfect match for our guiding principle and self-imposed goal to deliver the best possible quality and precision ‘despite’ speed,” says Christoph Ziegler, Production Manager at Huber GmbH.

Alongside automation, the decisive factor for Huber was that the VGrind 360S is suitable for ensuring consistently high-quality machining thanks to the wear-free linear induction motors on the X, Y and Z axes, and also reduces maintenance costs. With two grinding spindles situated one above the other and the grinding wheel set positioned at the C-axis pivot point, the VGrind 360 tool grinding machine enables efficient multi-level machining. This means that machining times can be reduced thanks to the shorter travel distances of the linear axes, which is also beneficial in terms of the speed promised by Huber.