The shop floor: A vision of the future

Hexagon recently staged its high-profile Future of the Shop Floor 2025 event at the facility of Mills CNC. Machinery & Manufacturing was an active participant in proceedings.

Hexagon’s Future of the Shop Floor 2025 was an opportunity for quality and production engineers to gain valuable insight from industry leaders. In particular, the event highlighted current challenges facing the manufacturing sector and how innovation, artificial intelligence (AI) and automation are already helping to overcome these issues and shape the shop floors of tomorrow.

Among many attractions on the event’s packed schedule was a Q&A panel session, hosted by Machinery & Manufacturing’s very own Publisher Laura Crawford. The panel, comprising both technology suppliers and users, boasted decades of experience and knowledge. Fielding the questions were: Greg Johnson, Marketing Manager & Internal Customer Services Manager at one of the world’s largest cutting tool manufacturers, OSG UK; Andy Heffer-Lamond, Sales & Project Manager at Ipswich-based metal fabrication solutions specialist HF Bond; and Jason Walker, VP of General Manufacturing at Hexagon’s Manufacturing Intelligence division.

Time for change

The panel was first asked to cite what they see as the biggest change currently taking place on UK shop floors?

“For me, it’s moving from reactive to proactive solutions,” said Greg. “With the introduction of the latest systems, manufacturers are not only able to analyse production but the entire supporting process. To use a buzzword, I see manufacturing getting ‘cool’ again. That’s good because exciting technology helps attract new engineers.”

From an end-user perspective, Andy reported automation, particularly the implementation of robotic welding, as the biggest change in recent times at HF Bond. To verify the comment of Greg, a young trainee at HF Bond has become very engaged with automated welding and is keen to become the company’s champion for this technology.

Indeed, the topic of automation was prevalent throughout the event, with experts from both Hexagon and Mills CNC available to share insights into the next wave of AI-driven robotics and smart factories are already reshaping the future of UK manufacturing. Visitors could learn how to integrate automation seamlessly into their production processes for maximum efficiency and output.

Connecting the dots

Laura’s next question was equally pertinent: Connected manufacturing – all hype or something UK manufacturing needs to harness?

“In truth, fully connected end-to-end manufacturing remains fairly visionary,” said Jason Walker. “Having said that, we’re seeing a growing number of shops gaining an advantage by starting to digitise certain processes. This activity also helps to identify areas that require improvement as manufacturers no longer rely on operators to flag issues.”

Added Andy: “Having a paper works order follow jobs around the shop floor isn’t the future. It’s time to move forward and make manufacturing process smoother and less subject to problems.”

Stumbling blocks

While there’s no doubting the advance of digitised, automated, connected technology to help shop floors achieve competitive gain, Laura asked about the ‘blockers’ preventing widespread investment. Andy stated that he sees resistance to change among sections of the workforce, particularly some senior-generation personnel, who perceive new technology as a threat to jobs.

“There remains a lack of understanding about the introduction of technologies such as automated welding,” he said. “The idea is for robots to take on repeat, somewhat mundane welding jobs and relocate or retrain workers to more skilled positions, adding value for both the employer and employee.”

Added Jason: “It’s almost paradoxical because we have the misconception around jobs and a shortage of manufacturers implementing these technologies, which makes industry less attractive to the new minds and skills we need. However, where we’ve seen manufacturers invest and attract new talent, existing personnel who were initially resistant to change start to see the benefits and often get a completely new lease of career.”

Greg listed two more so-called ‘blockers’: “Manufacturers sometimes fail to see the value that technology partners can bring in terms of technology implementation and maximising the benefits. Also, there’s occasionally a challenge in demonstrating a fast return-on-investment. Some of the digital thread technologies we’re talking about at this event might show modest returns initially before delivering far more substantial gains as the systems pervade through the business and staff take on more added-value roles.”

Closing the gap

This point prompted Laura’s next question of what skills do shop floors need now and in five years’ time?

“For me, the market needs digital engineers,” responded Greg. “Whether that comes from apprenticeships or an even younger level of education, I think we need a much wider conversation about how industry can develop and recruit digital engineers.”

Jason stated that although a requirement for traditional skills will remain, “we need a layer of digital skills on top as AI/generative begins to boost different stages of the manufacturing process.”

Another key opportunity at Hexagon’s Future of the Shop Floor 2025 was discovering how AI can transform manufacturing by enhancing efficiency, reducing waste and optimising production processes. Visitors were able to see how AI-driven analytics, predictive maintenance and smart automation can boost shop-floor operations through higher productivity and cost savings.

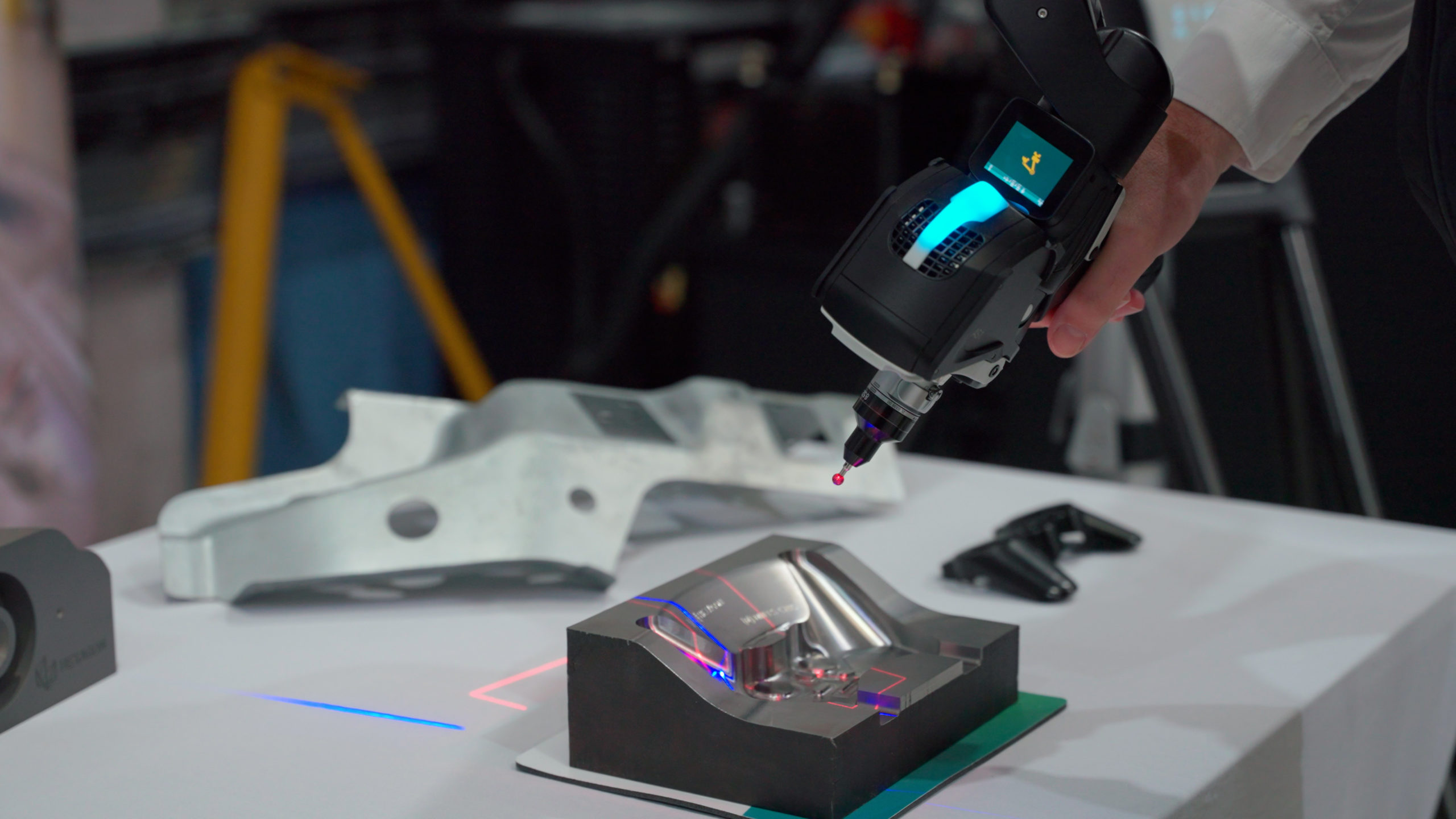

Those in attendance could also discover more about digital transformation, notably embedding quality at every stage of the manufacturing process. The digital transformation is already enabling some shop floors to leverage real-time monitoring, data-driven decision-making and automation to enhance consistency and quality control.

Magic button

Laura wrapped up the Q&A by asking the panel about the ‘magic button’ they would press to improve UK manufacturing overnight.

“My magic button would see more implementation of the innovation we have on offer in the UK,” said Greg. “I see so many tech start-ups and companies bringing amazing technologies to market. I want UK manufacturers to benefit from these advances over the coming years as it will help them become more competitive nationally and internationally.”

On a more political level, Andy said his ‘magic button’ would see the Government demonstrate greater understanding and appreciation of what manufacturing SMEs do for the UK economy.

“I think it’s clear we need more than one magic button,” stated Jason. “Mine would probably be overcoming the cultural barriers to adopting new technologies. It would be great if more manufacturers had a better understanding of the solutions that can make their production more efficient and sustainable: a kind of ‘enlightenment’ button.”