The right tool for the job

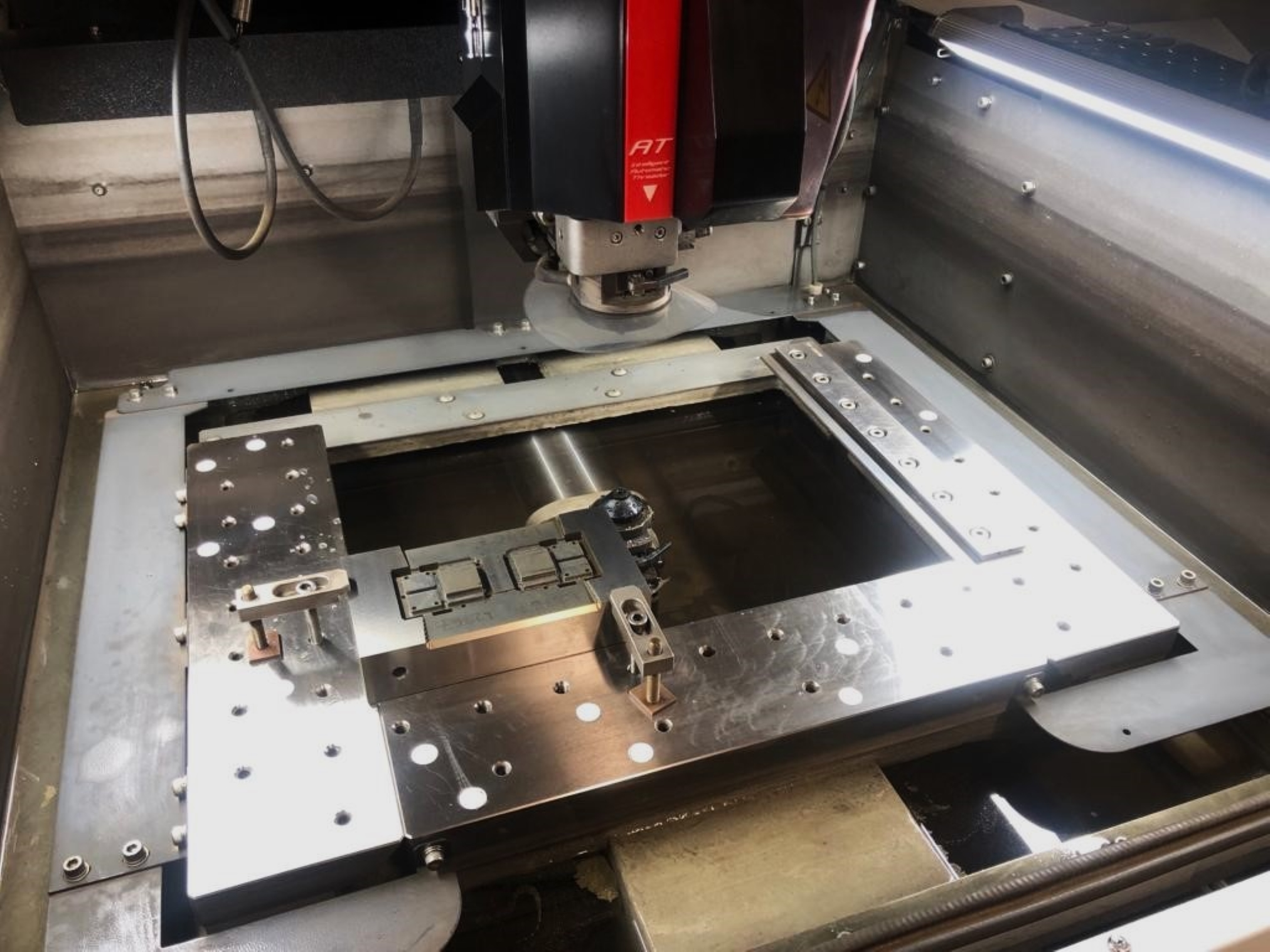

As a small subcontract toolmaking and machining business, Precision Engineering Services Ltd has carved a niche in the production of press and mould tools for the construction and DIY sectors. Producing everything from CNC machining and subcontract wiring of press and mould tools to maintaining and repairing precision tools for its clients, the Derbyshire business undertakes a significant amount of wire EDM work – this is why it has just invested in a Mitsubishi MV1200S wire EDM machine from the Engineering Technology Group (ETG).

The Buxton-based manufacturer has a selection of manual and CNC machine tools as well as a die-sink EDM machine and a wire EDM. However, with the company’s 12-year-old Mitsubishi BA8 wire EDM being the busiest machine in the company, its precision levels were sadly diminishing after more than a decade of non-stop operation. It was time for a replacement.

As the Managing Director who has taken over the family business he has worked at for almost 30 years, Chris Barlow says: “Our Mitsubishi BA8 wire EDM has worked fantastically well since the day we bought it. However, after more than 10 years of non-stop running, the ball screws were deteriorating and maintaining precision was becoming more of a challenge. We knew the machine ‘inside out’, so we could build in tolerance errors to maintain precision – but we knew that a new machine would be the best route forward. With linear drive technology and Tubular Shaft Motors instead of ball screws, the new MV1200S has a 12-year accuracy warranty and an Optical Drive System (ODS) that provides circular accuracy within 1μm, so we won’t have this concern in the future.”

The toolmaker took delivery of the new Mitsubishi MV1200S wire EDM machine in May, which replaced the previous Mitsubishi BA8. Alluding to why the company once again opted for a Mitsubishi EDM machine, Chris continues: “The Mitsubishi BA8 was a brilliant machine and if we had room for both, we would have kept it. When it came to picking a machine, we didn’t review the market as we knew that Mitsubishi was the best fit for our business. We did our due diligence when we bought the Mitsubishi BA8, moving from another brand to Mitsubishi. After a decade of highly productive precision machining with the BA8 – we have complete confidence in the Mitsubishi brand. Furthermore, we have familiarity with the Mitsubishi platform and transferring all our programs to the new machine was a seamless exercise.”

The installation of the new Mitsubishi MV1200S and its commissioning proved a stress-free transition with minimum disruption to Precision Engineering Services. As Chris continues: “Migrating our programs to the new machine was very easy. We could either edit the NC files on the machine control or we could run the programs through our EdgeCAM software, delete our old power files, select new processing parameters and re-run through the post-processors. This meant it only took five minutes to alter each of our legacy programs whenever a repeat job arrived.”

With the majority of programming done offline in the office with EdgeCAM, Precision Engineering Services is yet to yield the full benefits of programming on the Mitsubishi control system. As Chris continues: “Whilst our programming is still completed offline, there is a huge difference with the new Mitsubishi control panel, as it has the new intelligent D-CUBES control. The large touchscreen control is user-friendly and intuitive, and we now spend less time scrolling through option menus – everything is right there on the screen. The PC is also far more powerful and faster. The previous BA8 machine could take 15 to 20 minutes to set up for every different process, the MV1200S takes less than 10 minutes. This 5 to 10-minute saving may be small, but if you have to re-set the machine 5-10 times a day – the savings add up quite rapidly.”

Further improving the set-up and running time is the new wire re-threading system. As Chris continues: “On the old BA8, wire re-threading due to breakages or the re-setting of jobs would require the tank to be emptied every time. If you had a job with a profile that required 30+ holes, this would mean emptying the tank repeatedly, which would take 1 to 2 minutes every time. With the new MV1200S, the tank only drains to the mid-point and then automatically refills. This means a wire re-thread takes around 30 seconds as opposed to 1-2 minutes.”

“Another improvement with the new MV1200S is the axis positioning when the wire breaks. On the previous machine, if the wire broke, the machine would return to the start position, re-thread the wire and then jog through the programmed path until it returns to the wire break point – and then it would resume cutting. With the MV1200S, it re-threads the wire at the wire break point and immediately resumes cutting, saving valuable time. These incremental savings, like the machine setting on the CNC, are the culmination of lots of small updates that add up to considerable savings when it’s calculated every day or week.”

With regard to overall cutting time, Chris states that the generator on the previous machine was only one generation behind that of the MV1200S. “The speed of cutting is always restricted by the wire. However, features that would take four passes to finish on the BA8 can now be done in three or sometimes two passes. This improves our productivity by 25 and even 50% in some cases. For example, on a hole we would previously take away the slug with the first cut and follow this with a skim cut to take the hole or feature to size. The third and fourth cuts will be finishing cuts to obtain the high-quality surface finishes we need. With the MV1200S, the second cut to size is often of high enough quality – but we may sometimes need a third pass.”

This 25 to 50% productivity improvement is credited to the new V350 generator which has a significantly higher effective clock rate. The voltage is built up faster and with greater precision thanks to reduced capacitance loss. With a faster voltage build-up, spark duration and working voltage can be lowered, so customers like Precision Engineering Services will notice higher surface quality and lower power costs.

Chris concludes: “The machine is faster, more powerful and more precise than its predecessor. The more we familiarise ourselves with the machine and the intuitive new control system, the more we find features that can improve our productivity beyond the realms of what we thought possible. The service and support from ETG has been fantastic throughout and their EDM experts are always on hand if we need them.”