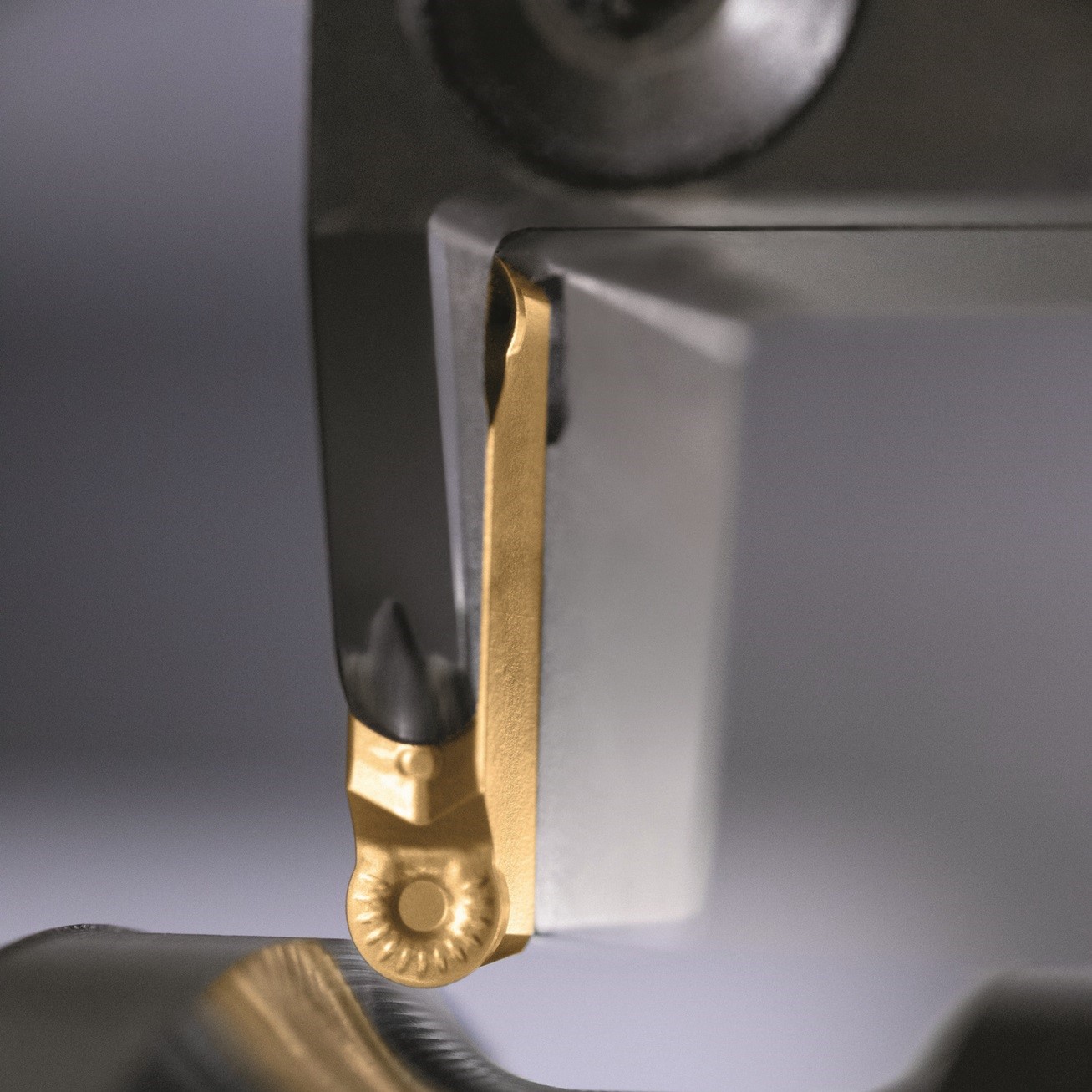

The new Walter Tiger·tec® Gold WSM33G grooving grade

The WSM33G is Walter’s first PVD grade to be specifically developed for the high loads that occur during grooving operations. The cutting tool material combines third-generation TiAlN with TiSiN to form a multi-layer coating with exceptional hardness and increased toughness. A special post-treatment reduces friction and ensures a smooth surface, thereby optimising chip removal and process reliability. Furthermore, the gold top layer makes it easier for users to detect wear. Walter uses the new PVD coating on single-edged SX cutting inserts with positive engagement and a self-clamping system. It can also be applied to indexable inserts from the double-edged DX18 system, where a second prism ensures stability in the insert seat.