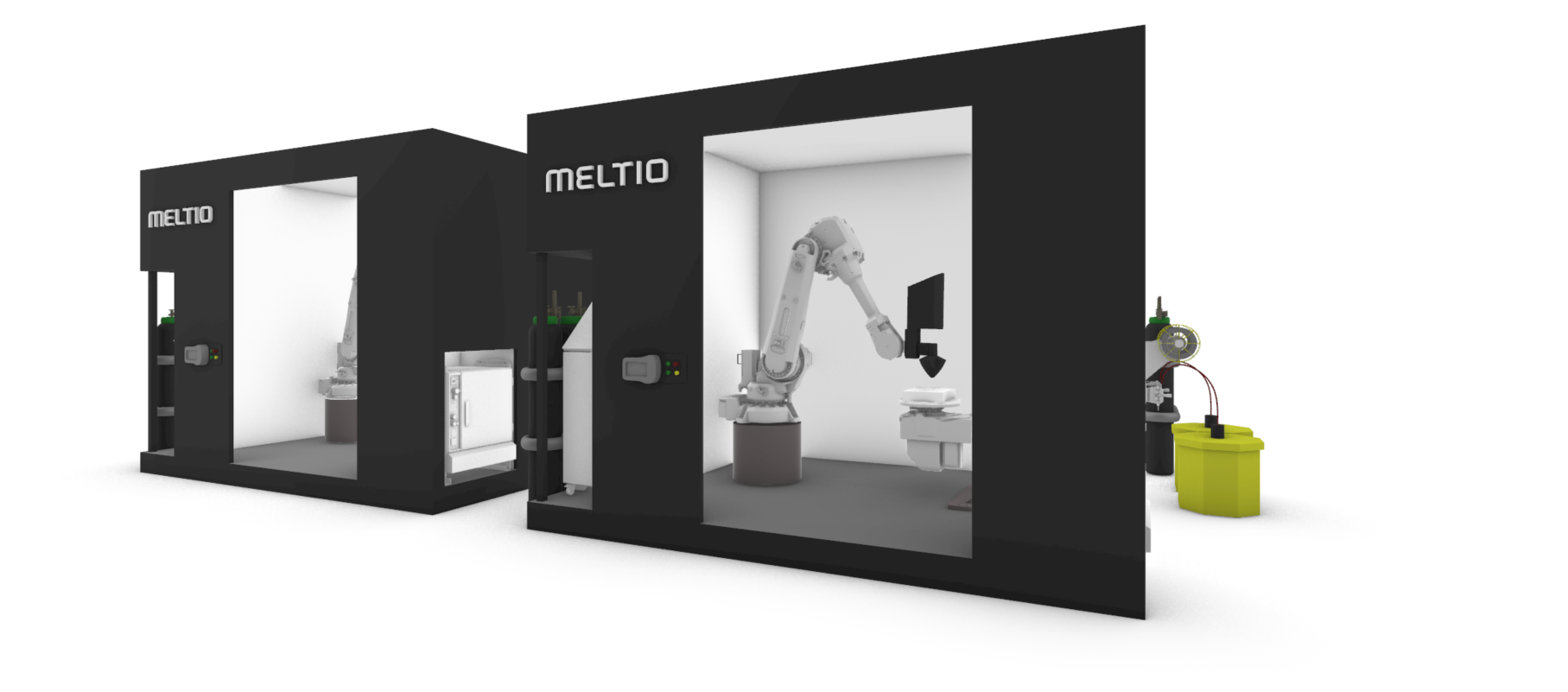

The new Meltio Robot Cell

Meltio has launched the Meltio Robot Cell, a turn key metal Additive Manufacturing solution to boost the performance of a industrial robotic arm in a safer, more reliable and highly accurate way by controlling the entire process including its recently launched slicing software Meltio Space.

Meltio Robot Cell is compatible with the open hardware platform that allows Meltio to integrate metal 3D head into any brand of robotic arm but in this case in order to propose a faster and better user experience is proposing a standardization, the Meltio Robot Cell. The volume and work area defined in the Meltio Robot Cell workspace meets all manufacturing needs using our industrial-level additive manufacturing technology to take full advantage of Meltio’s metal 3D printhead and be able to manufacture parts in an industrial environment autonomously thanks to its monitoring and safety features. Robot and positioner are installed on a self-supporting platform, laser safe enclosure together with Meltio Engine, Meltio Space and accessories.

With Meltio Robot Cell, Meltio company is fulfilling most of the applications that industry and integrators need when printing industrial metal parts and is the reason this standardization matches together with the possibility to build custom integrations with the help of meltio partners.

Meltio Robot Cell is designed as a plug & play system, with a single electrical power supply and a single inert gas supply. The environmental conditions are standard and this cell cannot be outdoors or unprotected from the sun and dust, it must be in a controlled environment. This solution allows the customer to receive a product ready to use for robotic metal 3D printing.

Meltio Robot Cell is certified and tested to operate with an ABB robotic arm as standard configuration and is aimed at all industries and is an evolution of the Meltio Engine Robot Integration as a base production model to enable industries to incorporate 3D printed parts manufacturing with the Meltio head integrated into a robot into their production systems.

Meltio Engine Product Manager, Alejandro Nieto is excited about this new innovation:

“Meltio’s main commitment with the launch of Meltio Robot Cell is to offer all types of industries the ability to manage the entire manufacturing process using our metal 3D printing technology consisting of a Meltio head integrated in a robotic arm and in a safe environment, in order to just produce parts. This new hardware system allows the customer to receive a ready to use cell for robotic metal 3D printing, removing the integration process and long assembly lead times. The Meltio Robot Cell has a specific area for every supply the cell requires on a daily basis, only connecting to the inert gas and electric supply is enough to start manufacturing.”