The future of surface cleaning is here now

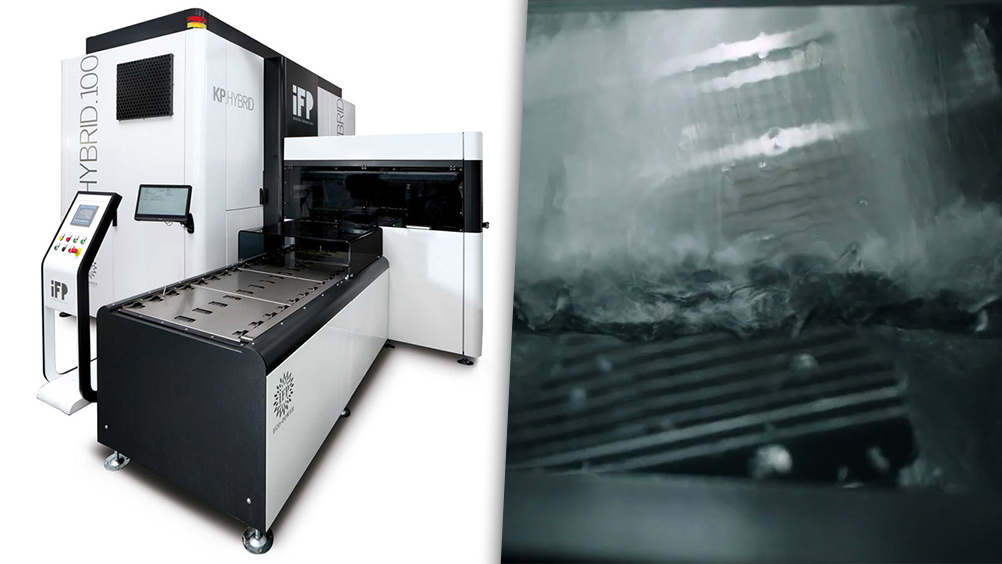

Kemet is introducing its latest range of advanced cleaning machines, designed to deliver superior performance through a fully enclosed vacuum treatment cycle. According to the company, every phase of the process ensures exceptional removal of residues, oils and contaminants from finished products while maintaining full environmental safety with zero harmful emissions.

The new systems combine multiple state-of-the-art technologies, including spray cleaning, basket rotation, aqueous solutions, modified alcohols, hydrocarbons, HFE and ultrasonic cleaning. This synergy guarantees high standards of precision, efficiency and sustainability, reports Kemet.

Key benefits include:

- Minimal loss of solvent, reducing process cost and environmental impact

- Distillation, separation and filtration of contaminants allows oils to be reused in machining processes and swarf/particles to be reused or economically disposed

- Uses modified alcohols with a flash point of more than 60°C under vacuum, so machines do not require ATEX approval, reducing build cost

- Ethernet connection provides online diagnosis of technical issues and predictive maintenance.

- Cleans component areas that are hard to reach with aqueous/HFE solvents, including blind holes and tubes.

The ideal applications are determined by factors such as production volumes, contamination levels and the dimensions of semi-finished products. Kleen Power Technology is trusted across a wide range of industries, including precision engineering, automotive, heat treatment, hydraulic components, springs, moulded parts, jewellery, watchmaking, medical and dental instruments, kitchenware, and electronics.