The dawn of a new grinding era

In an era where precision, efficiency and adaptability are crucial to advanced manufacturing, Dawn Machinery says it is redefining expectations in grinding technology. With over three decades of R&D experience, the company has built a strong reputation for producing special-purpose machines tailored to a wide range of machining needs. Its latest innovation, the Dawn DN series of vertical grinding machines, marks a milestone in high-precision grinding.

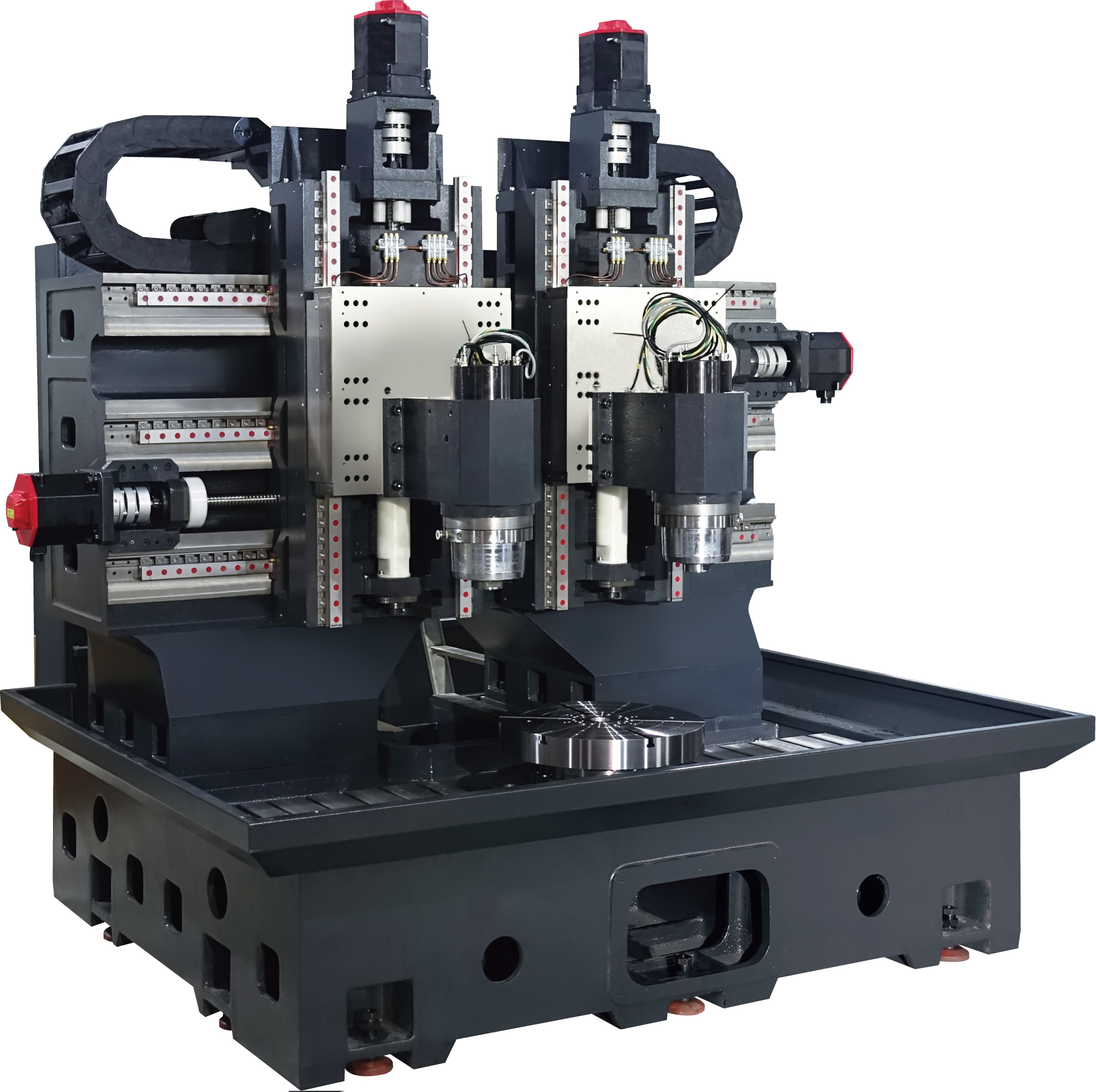

The DN series harnesses the inherent strengths of vertical grinding design. With models ranging from DN 200 to DN 2500, the machines are engineered to support swing diameters from 280 to 2500 mm and workpiece weights up to 10,000 kg. The vertical layout simplifies the handling of large and heavy components, improving stability during clamping and allowing easy access via overhead hoists.

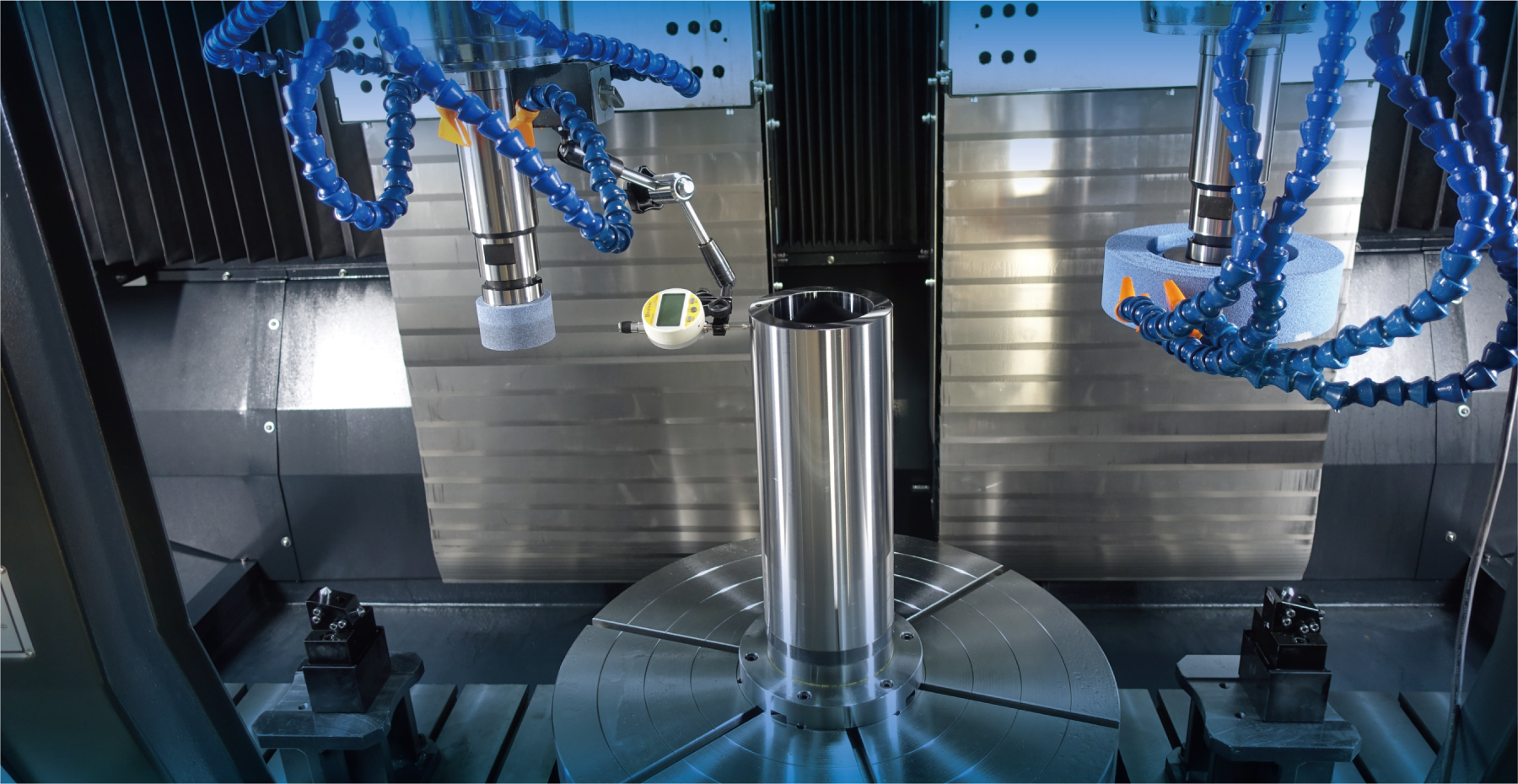

Now available in the UK from RK International Machine Tools, the DN machine features a double-column structure that enhances rigidity, with fully enclosed covers and oil mist reclaiming systems that contribute to a clean and controlled environment. The design supports a wide variety of configurations, including single or dual spindles and optional automatic tool changers, making the DN series highly adaptable across industries.

The user interface is another stand-out feature. With conversational programming, operators can execute complex grinding processes without writing traditional code. Siemens CNC controllers with large touchscreen displays provide an intuitive control experience, supported by Dawn’s extensive grinding application knowledge built into the system.

Precision is central to the DN series. The machines offer ultra-fine positional accuracy, with axis movements measured in increments of 0.0001 mm and turntables delivering sub-micron rotational precision. Build components such as Swiss, German and Japanese guideways and ball screws, along with optional linear motors, ensure lasting performance and minimal wear.

A full range of standard and optional accessories is available to expand the machine’s capabilities. These include oil mist extractors, magnetic filters, diamond dressers, in-process measurement systems and collision avoidance sensors. Optional touch probes and online gauges support real-time inspection and quality control.

Simon Rood, General Manager at RK International Machine Tools, reflects on the recent developments: “Having spent time with the Dawn Machinery team and observing the build of the DN-2502 two-spindle machine, I was genuinely impressed by the quality and precision of the engineering. The application scope from ID/OD grinding to cam and taper profiles is vast and growing.”

Dawn Machinery’s commitment to turnkey solutions sets it apart. Through the company’s partnership with RK International, Dawn Machinery offers a complete support package from initial consultation and time studies to installation, training and aftercare.

Alan Hsu, CEO of Dawn Machinery, highlights the importance of local support: “With RK’s deep grinding knowledge and customer service ethos, we can ensure our machines deliver value and performance worldwide.”