Tebis 4.1 Release 10: Everything in a single CADCAM software solution

The focus of the latest Tebis 4.1 Release 10 is Tebis SmartOps, which supports end-to-end automation of CADCAM processes within Tebis software. Users can now master many design and manufacturing tasks faster and more easily, or reproduce them at any time. Tebis announced 4.1 Release 10 will be available in autumn 2025.

Tebis SmartOps

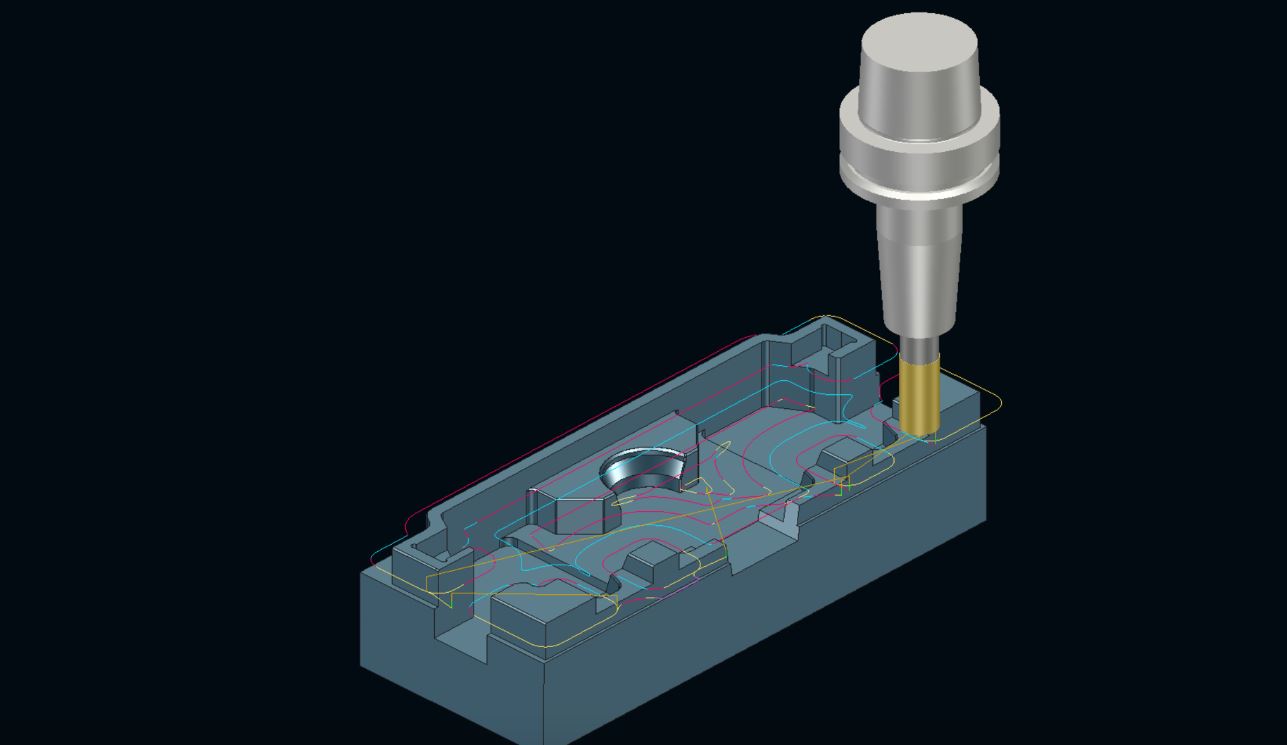

Whether manufacturing simple or highly complex parts, every manufacturing process involves reoccurring tasks. With Tebis SmartOps, the company says users can rely on intelligent, sophisticated CADCAM operations that provide full automation thanks to powerful templates.

SmartOps can be used with the complete set of Tebis function modules. Users can tailor SmartOps to specific tasks, with all collected manufacturing know-how managed in libraries. According to Tebis, production will become smarter, faster and future-proof.

The new technology has already been put to use by several project partners, as automation product manager Torsten Fiedler reveals: “Our project partners are especially excited that Tebis SmartOps can be set up entirely within the familiar CADCAM environment without the need for special scripting or programming knowledge. This is where Tebis SmartOps stands out from competitor products.”

He continues: “They are also enthusiastic about the ability to adapt the CADCAM process flexibly at any time. Users are guided through individual process steps by a wizard and can intervene as necessary. The user can quickly and easily update the entire manufacturing process using parametric functions.”

Automation with Tebis SmartOps makes the difference

CAM: milling

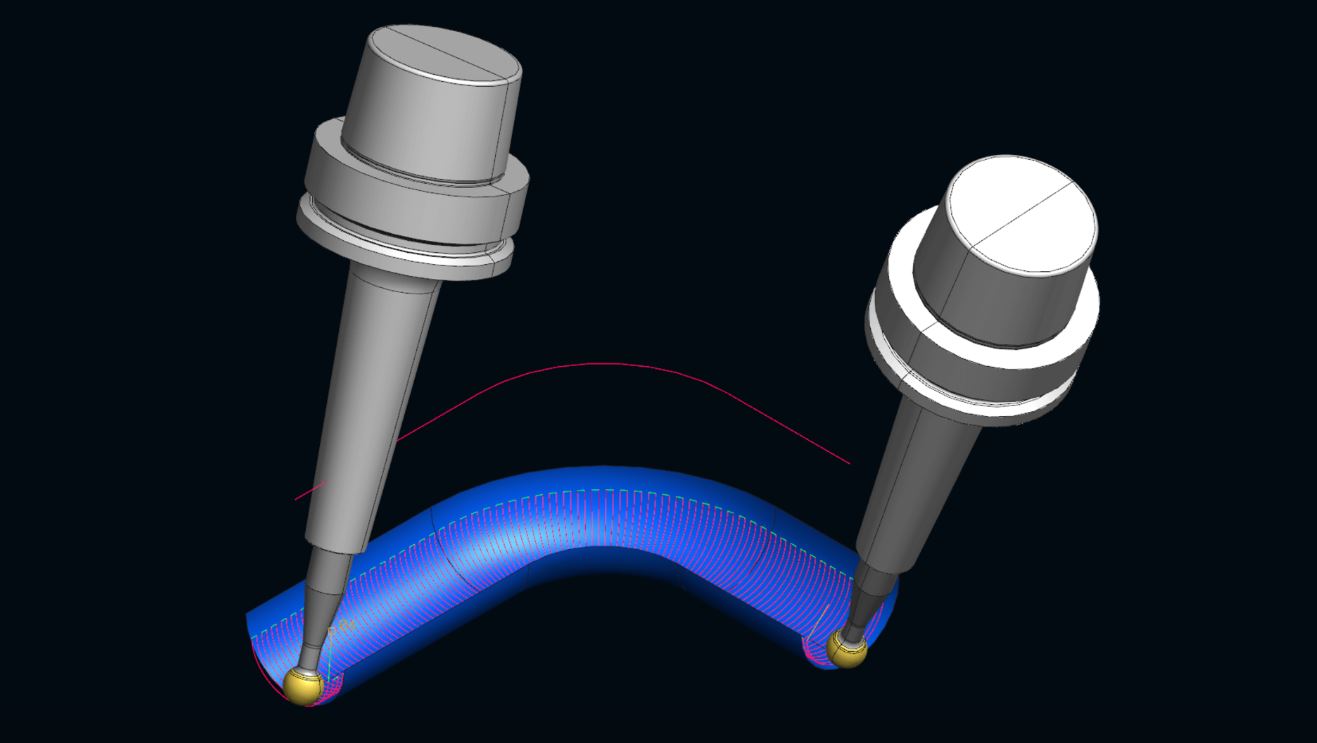

Tebus has made tool-path programming for five-axis simultaneous machining even easier. Users can now select a curve to calculate the tool orientation. They can also specify an angle to improve cutting conditions further.

In addition, machine retract movements can now be accurately controlled in Tebis for all five-axis simultaneous milling functions. Retracts can be processed at rapid traverse or normal feed rate, optimally matching the retract movements to the machine type and control.

20% faster roughing

The roughing options have seen further improvement. Thanks to optimised infeed movements, high feed-rate cutters that enable very high metal removal rates, especially for large parts, can now be used even more efficiently and with less tool wear.

New options for combined roughing operations also ensure longer tool life and up to 20% faster processing on the machine. If specific areas are excluded from machining during roughing, additional filtering options can be used for even more targeted control of subsequent machining.

Optimised connecting paths for three-axis machining centres

Tebis supports full control of machine control systems in which the linear axes are not synchronised. When potential for collision exists, the connecting path is automatically generated at a safe height. This lets users exploit the full potential of older three-axis machining centres. Positioning takes place at maximum speed.

CADCAM: automation

Tebis customers now benefit from even greater automation when machining freeform features. As when machining using ruled features, users can now specify in the tool search whether the tool should be automatically replaced with a longer one in the event of possible collisions. Alternatively, operators still have the option of controlling the collision check manually like before.

Freeform features are also even easier to prepare for automated CAM programming. They can be disconnected, linked or broken interactively.

CAD: 3D design

In some cases, to avoid residual material at the edges and protect cutting edges, freeform surfaces have to be extended tangentially for optimum milling results. In Tebis, this is fast and automatic.

The Tebis parametric solution is extremely close to the actual practice of machining. Users can interactively adjust the result and update it globally with a click of the mouse.

CAD: reverse engineering

Tebis now offers efficient, highly automated generation of wire-frame models from scanned data sets. The generated wire frame can then be optimised in a flexible manual process.