TaeguTec unveils WIN-SWISS modular tooling for Swiss turning

Cutting tool specialist TaeguTec has unveiled its WIN-SWISS modular head and holder system. Designed to enhance productivity and efficiency in Swiss turning centres, the new tooling solution tackles the long-standing challenge of time-consuming insert changes while improving the rigidity and precision requirements of sliding-head turning applications.

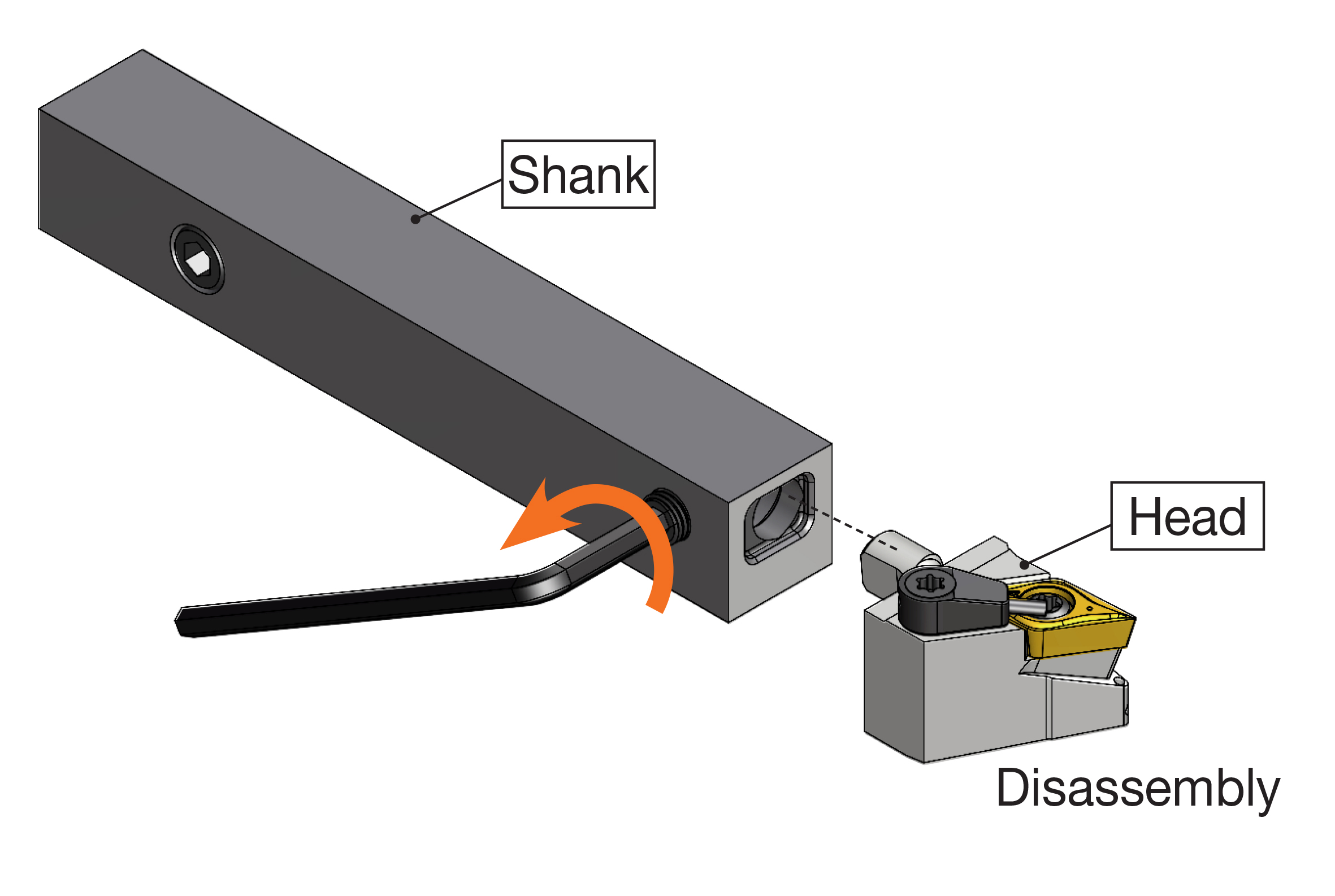

The WIN-SWISS system allows operators to change inserts outside the machine by detaching only the modular head, while the shank remains securely attached to the tool post. This approach eliminates the necessity for the complete removal of holders, reducing set-up time and minimising production downtime.

Performance testing shows that the WIN-SWISS system achieves a 77% reduction in tool change time compared with conventional holders, reducing typical changeover periods from 108 seconds to just 25 seconds. This improvement translates to enhanced productivity and lower manufacturing costs for precision machining operations.

WIN-SWISS incorporates TaeguTec’s proprietary fastening technology, which features a unique combination of screw clamping and tapered face contact, delivering machining stability comparable with conventional integrated holders. The robust assembly mechanism utilises a taper design combined with lever principles to ensure rigid clamping between the tool shank and the heads. This concept provides repeatability and maintains dimensional deviation within +/-5 microns, all while requiring only a single rotation of the clamping screw.

The modular design philosophy extends beyond mere convenience, providing inventory benefits through the ability to mount multiple heads on a single shank. This flexible interchangeability enables manufacturers to optimise their tooling investments and maintain comprehensive machining capabilities across various applications.

WIN-SWISS offers a comprehensive selection of modular heads tailored to Swiss turning requirements, including external turning, Y-axis machining, parting, grooving and back-turning. It features TaeguTec’s COOL-BURST high-pressure coolant delivery technology, which provides both top and bottom coolant supply. The system directs concentrated high-pressure coolant precisely to the cutting edge, enhancing chip control, prolonging tool life and facilitating higher machining parameters.

TaeguTec has engineered the WIN-SWISS system with an error-proof assembly mechanism that prevents incorrect head and shank combinations. Furthermore, the system’s design philosophy prioritises operator safety and ease of use by minimising the risk of losing spare components and inserts during simplified changeovers, a common concern with traditional integrated holders.