TaeguTec expands Maxi-Rush exchangeable-head milling series

TaeguTec’s Maxi-Rush range of exchangeable solid-carbide end mills has received a major expansion. The expanded line now includes a wider range of configurations, offering customers operational flexibility across various manufacturing applications. From standard milling operations to specialised tasks, the expanded selection addresses nearly every modern machining requirement.

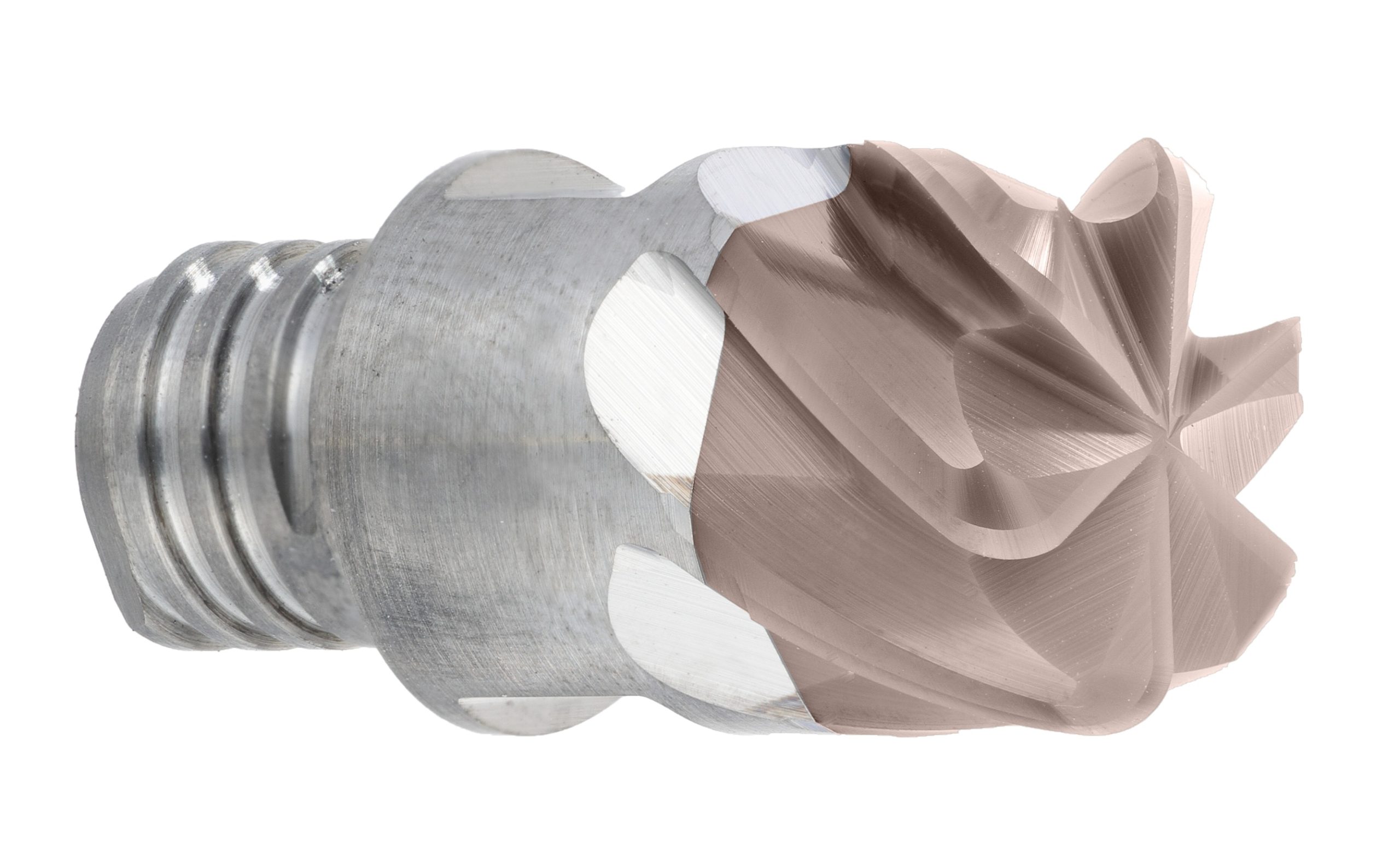

The Maxi-Rush series already delivers productivity advantages while addressing the challenge of reducing tool replacement time, carbide consumption and costs. It supports rapid head replacement in seconds rather than minutes, and offers high rigidity with a patented clamping mechanism that ensures both strong clamping forces and micron-level repeatability. According to TaeguTec, the series rivals the performance characteristics of solid -arbide tools while offering the economic advantages of modular tooling.

The latest expansion includes numerous enhancements that broaden capabilities, incorporating proven high-feed milling geometries that maximise material removal rates. Notable new additions feature MXES-R four-flute, unequally spaced, variable helix cutting edges that reduce vibration during challenging machining operations. Suitable for optimising chip evacuation and minimising cutting forces when performing slotting, side and face milling, and trochoidal milling, TaeguTec says MXES-R is the ultimate all-rounder.

Also new is the MXEE-R-1.5D four- and six-flute roughing heads with 1.5xD flute length. These heads provide high performance thanks to their chip-breaking cutting edge, which facilitates high feed rates and smooth machining compared with conventional milling methods. This capability signifies an advancement for manufacturers aiming to achieve higher material removal rates while maintaining superior surface finish.

For high-feed machining with shallow depths of cut, the new MXFX-04/06 series delivers high productivity. It employs optimised cutting-edge geometries that facilitate feed rates increases without spiking power consumption. Available in TT5513 and TT5523 grades, the MXFX-04/06 enhances material removal rates, leading to time and cost savings across production operations.

Other new variants include the MXED-I07/I09-1.5D long cutting edge design featuring seven- and nine-flute configurations with variable helix and pitch technology. These new products not only achieve smooth surface finish during side milling by reducing vibration, but also improve productivity and tool life through a higher number of cutting edges. Engineered to address the demanding requirements of mould and die manufacturers that previously relied on solid-carbide end mills for roughing, the versatile series is complemented by the MXFM-I06 six-flute face milling heads that provide precision facing with significant tool life benefits. Other new systems added include the TTRD-A60 and TTRD-W55 threading solutions that accurately address ISO and BSW threading requirements.

The expansion showcases the introduction of the TT5513 grade, which offers high wear resistance. This new grade features an ultra-fine substrate with optimal toughness characteristics, providing abrasion resistance through its sophisticated nano-crystalline structured AlTiN layer. The anti-abrasion and crack-resistant PVD coating delivers high performance for demanding mould steels and pre-hardened steel applications.

In addition to the MXEE A02 and MXEE A03 which has shown high performance in machining aluminium alloys widely used in the aerospace and automotive industries, the newly released MXEE RA03 features a chip-breaking cutting edge that reduces cutting load and vibration during machining. Minimising chip volume, it enables faster and higher-volume machining.

The series expansion also encompasses a new range of shank systems designed to optimise performance across various machine configurations. New steel shanks featuring step-neck designs (MXSSD-S), carbide variants (MXSSD-C) and tungsten options (MXSSD-W-A) offer high rigidity and precision in extended reach applications. The taper neck systems in the MXTSD series accommodate complex geometries while maintaining stability and vibration resistance.