Supporting a greener future for transport with a complete range of solutions

A rapid increase in battery electric vehicle (BEV) development, manufacture, and implementation, shows that electric vehicles are not only the future but are, in fact, the present. The automotive industry is on the brink of colossal changes and soon our perception of cars and transportation will alter completely.

ISCAR, a company with many years of experience in the production of metal cutting tools, offers unique, cutting-edge solutions for the new BEV Industry. As a leader in providing productive and cost-effective machining solutions, ISCAR strives to stay up to date with all the new trends and technologies and be a part of a brighter, greener future.

The following outlines some of the common component machining processes in the BEV industry and some of the leading possible machining solutions and recommendations for each part.

One of the most notable trends of the electric vehicle powertrain is its simplicity. There are far fewer moving parts compared to the traditional internal combustion engine (ICE), therefore manufacturing time, and cost dramatically drop when producing BEV’s.

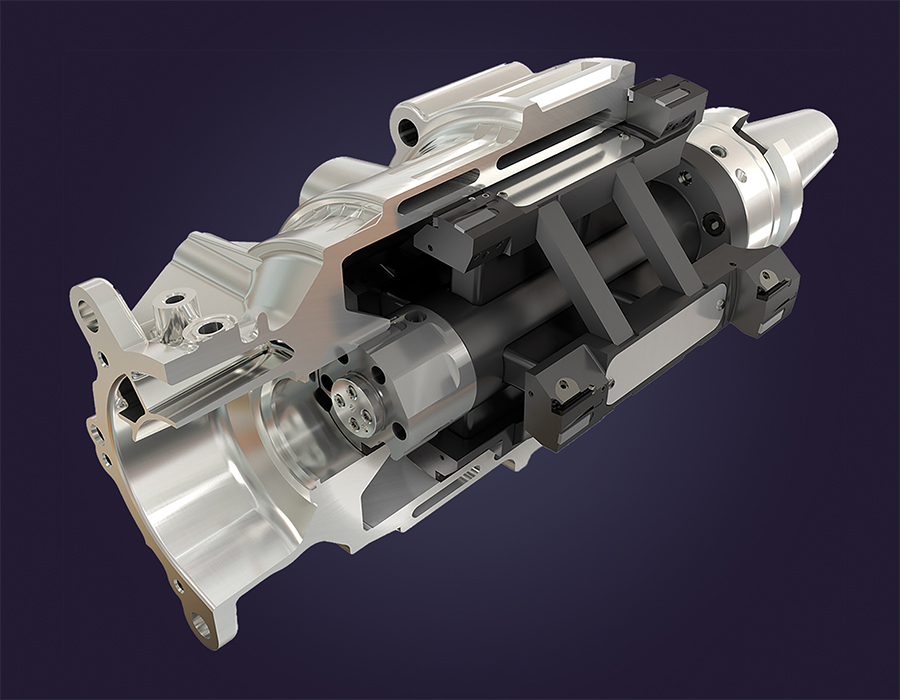

One of the main components of an electric motor is the motor housing (stator) made from aluminum. A special approach is needed to achieve this part’s critical key characteristics of lightweight, durability, ductility, surface finish and precision, including geometrical tolerances. The partially hollow form represents an additional challenge and maintaining low cutting forces is essential for roughness and cylindricity requirements.

ISCAR’s complete machining solution for this process has facilitated the transformation from the standard costly lathe-based process to an economical machining center. Our aim is to reduce scrapped parts and reach an optimal CPK ratio. (Process Capability Index- producer’s capability to produce parts within the required tolerance.)

The most challenging operation in machining the Aluminum stator housing is the main diameter boring and reaming. Because of the trend to use low power machines, the tool’s

large diameter and long overhang require creative thinking to minimize weight and spindle load while maintaining rigidity. Exotic materials such as titanium and carbon fiber are used for the tool body, as well as the welded frame design.

The use of Finite Element Method (FEM) helps resolve the obstacles associated with this challenging application by enabling the consideration of many parameters, such as cutting forces, displacement field during machining, natural frequency, and maximum deformation.

Unlike the ICE, the electric motor generates its maximum torque from a standing start. This means it does not require a complex transmission system to operate. A simple reduction gear is enough for the average electric vehicle. This reduction gear sits between the stator housing and the gear cover.

To maintain concentricity between bearing seats of the stator and gear cover, the reaming operation must be performed in the same machining sequence.

For this operation, ISCAR provides a special “push and pull” reaming type tool with adjustable PCD blades that manage to retain the geometrical tolerances required in different inner diameters on this Aluminum part.

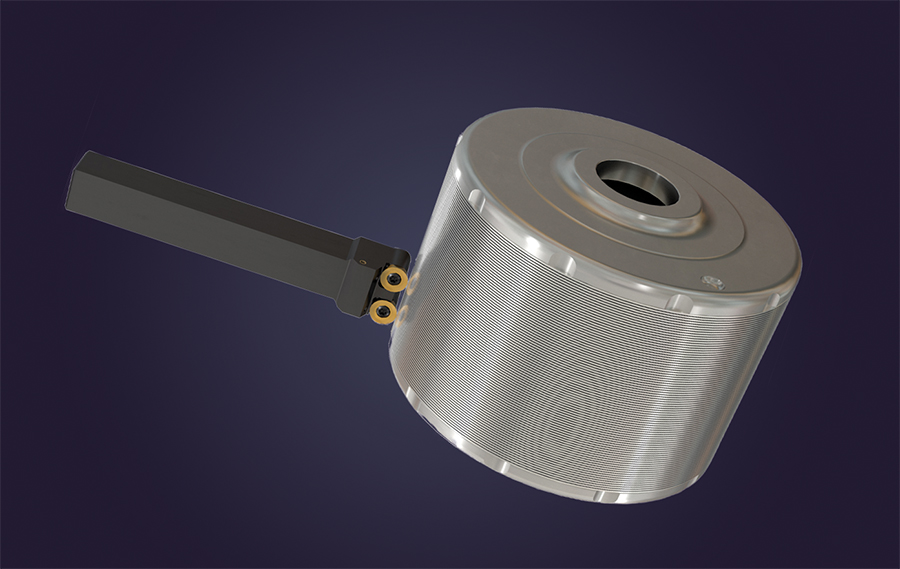

The rotor consists of many stacked plates of electric steel. Lamination sheets are used instead of a solid body to reduce current loss. The surface must be completely clean of chips, oil, water, dust or dirt, and coolant fluid cannot be used, only air. This is a challenge as a lot of heat is generated on the cutting area and the fragmented chips stick to the surface. Surface finish requirements for this interrupted turning operation remain strict.

ISCAR has overcome these challenges by developing a combined tool with coolant holes both on top and bottom of the cutting edge to cool and blow away the chips. The two round inserts are positioned for semi finish and finishing operations, generating an excellent surface finish.

As batteries are replacing fuel as an energy source for vehicles, the battery case is an integral component of the car design. Large size and light weight requirements make aluminum a natural choice for manufacturing this part. But, when dealing with high-end supercars or sport cars, every unit of weight counts. That is why some automakers turn to the use of carbon fiber reinforced plastic (CFRP), which offers lighter weight, high rigidity, and lower thermal conductivity than aluminum.

ISCAR has a wide array of tools specially designed to machine aluminum and CFRP, which provide productive and economical solutions for any application. For example, for the required drilling holes, the SUMOCHAM indexable head drilling line offers a variety of geometries suited for specific materials. For drilling Aluminum, ICN heads are designed with a sharp cutting edge and polished rake face. ICG heads feature a chip splitter for better chip removal when working with a long overhang. For drilling CFRP, special ICF geometry is available with diamond coating – this drilling head is designed to overcome all the typical CFRP machining failures such as delamination.

The Automotive industry has already started changing its direction, moving toward the new challenging era of BEV production, but without a doubt using ISCAR’s cutting edge technology and innovative solutions will keep the part manufacturer ahead of the industry and help adapt to the growing changes needed to make a greener and healthier place to live.