Subcontractor grows by investing in Hurco machines

Factory 33 was established in 2016 in a factory unit in Carterton, Oxfordshire, as a subcontract manufacturer of medium to large batches of components to fine tolerances in short lead-times. It is maintained to exceptional standards of cleanliness commensurate with the expectations of customers in the food, scientific, medical, motorsport and other discerning industries.

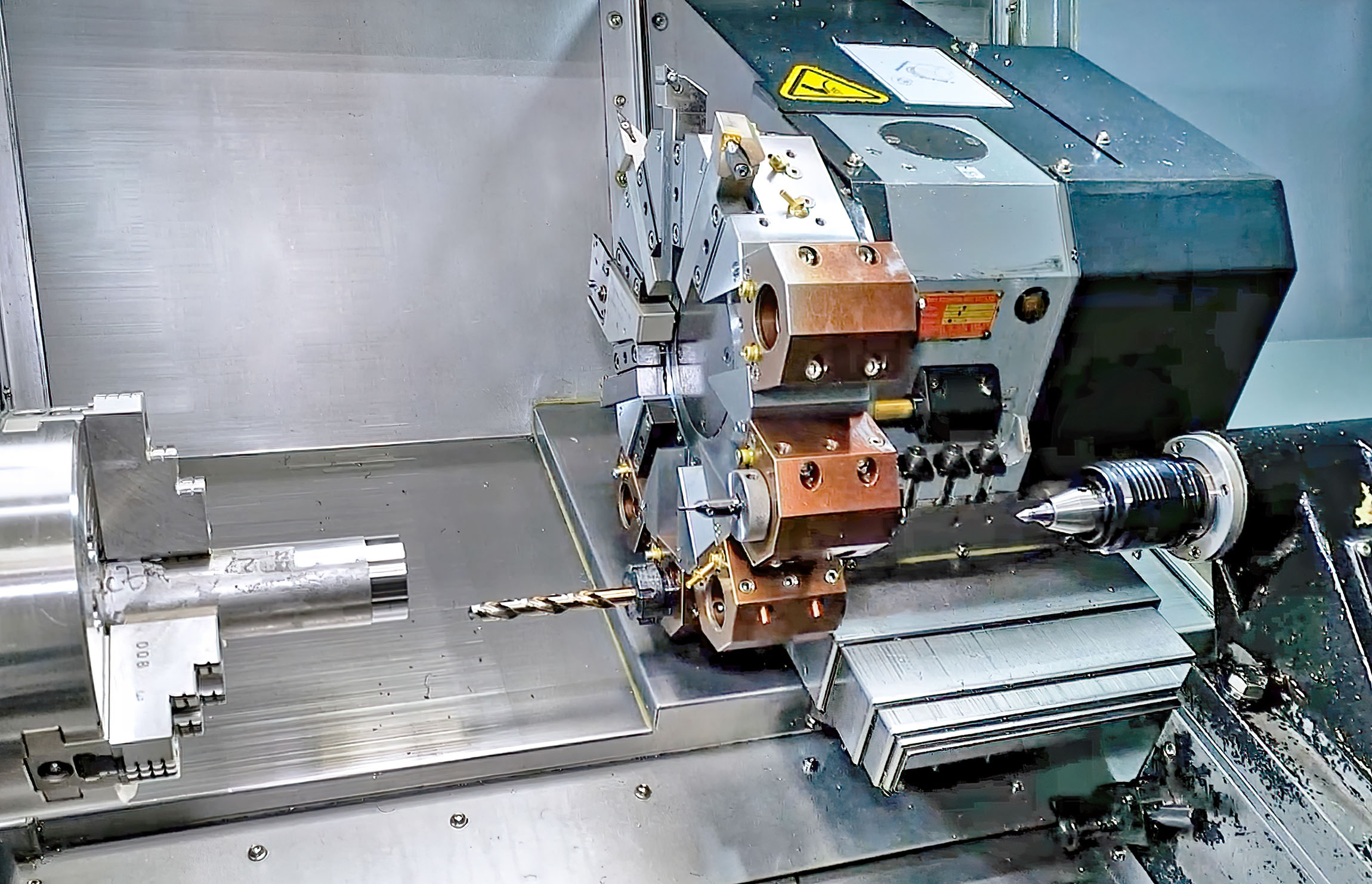

An extensive variety of materials is processed from aluminium, brass and copper to stainless steel, titanium, Inconel and a variety of different plastics, principally on machining centres and a CNC lathe from Hurco Europe, High Wycombe.

When they started Factory 33, owners Martin Krzywina and Karina Ringer-Krzywina, both time-served engineers, had more than 10 years’ experience in the design and manufacture of precision engineered components for numerous sectors including Formula 1, cryogenics, aerospace, nuclear and medical. They invested initially in a Hurco VMX30Ti 3-axis vertical machining centre with a 4th axis rotary table and a Hurco TM8i lathe, since which time additional 3- and 5-axis VMCs have been bought.

The most recent purchase is a Hurco VMX30UDi 5-axis machining centre supplied with linear scales and through-spindle coolant as standard, as well as a 40-station magazine with swing-arm toolchanger. The direct-drive SK40, 15,000 rpm spindle can deliver 15 kW of power and travels are 763 mm x 508 mm x 520 mm. Control is by the proprietary WinMax 5 twin-screen CNC system.

Managing director Mr Krzywina commented, “We love the Hurco control and especially its graphics. You can show not only solid models but also the toolpaths. It gives so much confidence when running 5-axis programs.

“You can follow the actual cutting cycle in real time on the screen, so you always know where a tool is in the machining area, even if you cannot see it through the coolant.”

He is impressed by the coolant delivery system, which he says is one of the best he has ever worked with, particularly as there is no loss in pressure irrespective of the coolant level in the tank. He also singles out for praise the direct-drive spindle on the 5-axis machine, which produces surface finishes that he describes as “impeccable”.

Mr Krzywina is also a fan of the ‘interrupt-cycle’ button, with which he can pause any job mid-cycle and change inserts on a mill or check tools. He is then able re-start the program exactly where it was stopped. This can be done at any time while the program is running and works equally well for NC and conversational programs.

The sustained growth of Factory 33 has allowed extra services to be added that are tailored to customers’ needs, underpinned by continued investment in high quality machine tools from Hurco. Design services are provided with the aid of EdgeCam CADCAM software, which also handles CAD models supplied by customers.

An ongoing focus on accuracy and fast turnaround times, and the ability to offer various finishes and treatments as well as kits or assemblies plus consignment stocking of parts, are enabling the subcontractor to continue to win new customers.