Start-up jets ahead

Based in County Durham, Waterjet-Tec Ltd is a new subcontract cutting company already making waves, thanks to its investment in an Optima O-Series 420 waterjet cutting machine from Kerf Developments. Founded by experienced entrepreneurs Terry Stewart and Peter Robinson, the business operates alongside its sister company,Laser Profiling (North East) Ltd.

The opportunity arose when a local waterjet company went into administration. “I had retired after selling a previous business, but we saw a gap in the market that was too good to miss,”explains Peter Robinson. “We secured premises, found the right machine and hired skilled staff.”

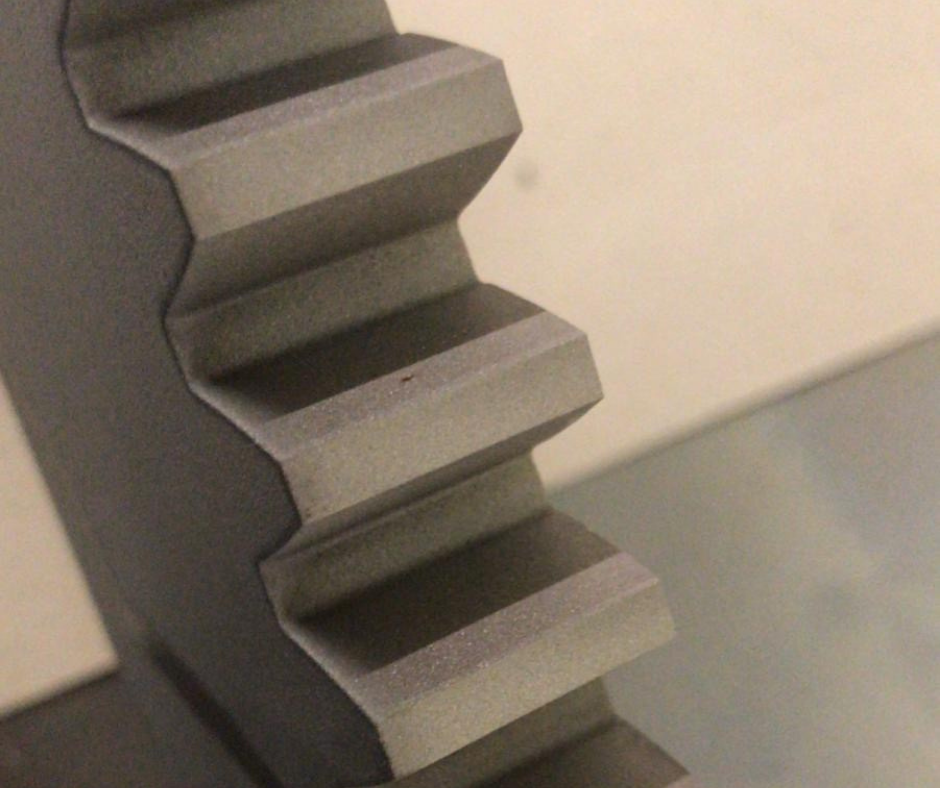

With decades of experience in sheet metal cutting, the directors recruited two engineers with specialist knowledge in waterjet technology. Terry Stewart says: “We identified two clear opportunities. Firstly, to cut a wide range of non-metallic materials that lasers and plasma cannot handle. Secondly, to serve industries such as aerospace and defence where heat from other processes risks altering material integrity.”

As their first major investment, machine reliability was crucial. The partners wanted twin cutting heads for productivity and a supplier with proven service back-up. “Too often we have been let down by poor spares and support,” adds Peter. “Kerf was the standout. Their Rochdale base holds spares in stock, meaning same or next-day availability, unlike overseas rivals.”

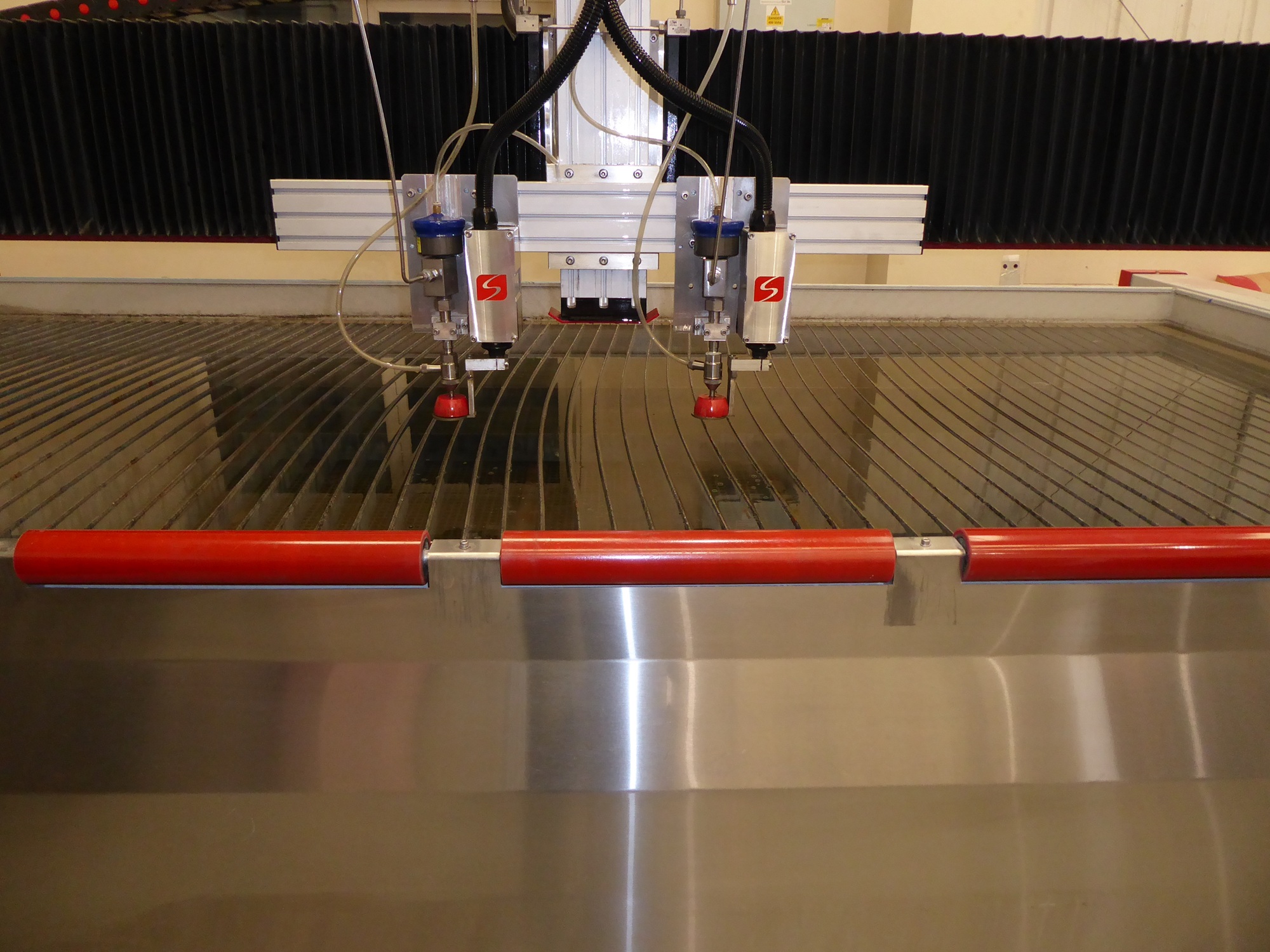

Waterjet-Tec chose the Optima O-Series 420, a 4 by 2m machine with two cutting heads powered by a BFT ECOTRON® pump delivering pressures up to 4000 bar. This enables precision cutting of almost any material up to 200mm thick.

Productivity and Performance

The machine was commissioned in April and has already transformed throughput. Terry Stewart explains: “Many defence and offshore projects can only be cut with waterjet. The twin-head capability lets us cut twice as many parts as competitors, making us both faster and more cost-competitive.”

Large projects, such as profiling subsea nylon pipes, are also handled with ease thanks to the Optima’s rigid frame, twin-drive bridge design and high-speed servo system. Lights-outrunning for up to 20 hours unmanned is already in place, with further automation under review.

The machine’sIGEMS CAD/CAM nesting software adds further efficiency, enabling fast programming, quoting and material savings. “It gives us a real edge in responsiveness,” says Stewart.

Concluding, Peter Robinson adds: “Kerf has supported us every step of the way. With the Optima 420, we expect a rapid return on investment and forecast an annual turnover approaching £1m.