Sodick UX450L machining centre has major impact on manufacturers since launching in spring 2024

Introduced to the UK in spring 2024, the Sodick UX450L machining centre from Sodi-Tech UK has already made a major impact on manufacturers. This high-speed machining centre with linear drives comes with a 10-year guarantee on positional accuracy, with UK machine shops already keen to take advantage of its performance.

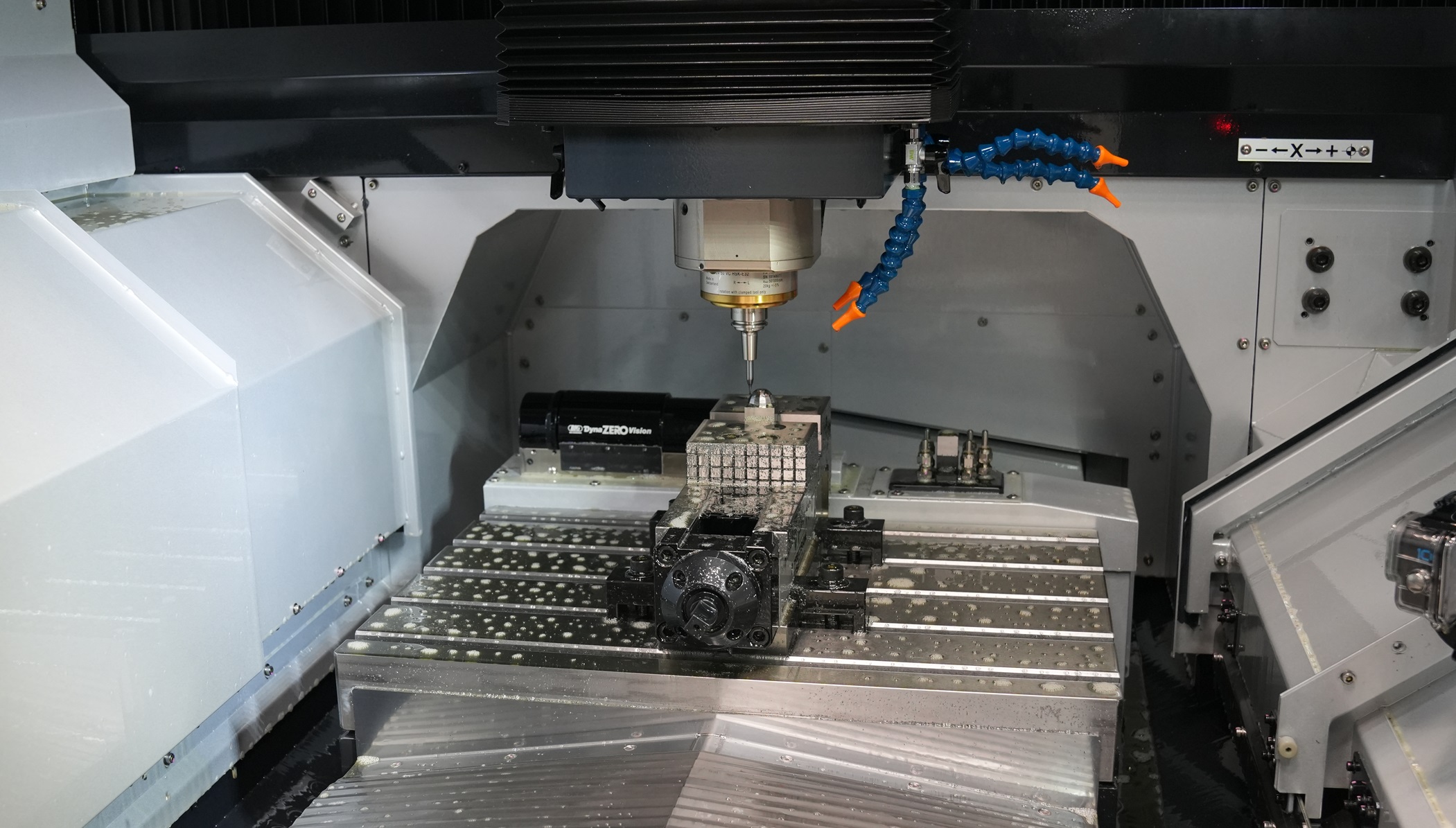

To push boundaries, a machine tool must have a solid foundation, and Sodick offers this attribute with its gantry structure and a low centre of gravity that combine to deliver stability and rigidity. Furthermore, coolant passes through the structure that covers the spindle body to suppress thermal displacement.

Conor Plaskitt, Technical Sales Manager at Sodi-Tech UK, says: “We’re very well known for EDM but not so much for high-speed machining. However, the two work together very well. For a typical copper or graphite electrode manufacturer, the Sodick UX450L can provide the solution. If you look at processes where spark erosion isn’t always necessary, use the UX450L. It’s suitable for hard milling where manufacturers want ‘mirror-like’ surface finishes and very tight tolerances. The machine offers a 40,000 rpm spindle, alongside the ability of the machine kinematics and axis movements to start and stop very quickly with pinpoint precision.”

From a specification perspective, the Sodick UX450L has X, Y and Z-axis travel of 450 x 350 x 200 mm supported by a 600 x 400 mm work table. The machine has a 16-position automatic tool change facility and linear glass-scale feedback on the X, Y and Z-axis linear motors, all of which benefit from temperature control.

Looking at potential parts for manufacture on the Sodick UX450L to eliminate time-consuming processes on alternative machines, Plaskitt says: “The machine is suitabel for complex components that need very high surface finishes, such as mould tools. Our UX450L can achieve high-quality surface finishes that eliminate the requirement for time-consuming grinding or secondary polishing. Likewise, the machine can replace jig grinding operations.”

The LN4X NC control unit offers intuitive interaction through its 19-inch touchscreen. Easy-to-use programming software prompts the operator to input simple data parameters for immediate gains in machine uptime. Other features include a sleep mode function that minimises power consumption by recognising idle times such as program stops, coolant stops, axis movement stops and more. Furthermore, the SEPTune machining support system delivers simple and smooth operation with just four steps to the machining operations.

To streamline productivity, Sodick has introduced its MotionExpert-S simulation software and the EF-Tune machining feed rate software. MotionExpert-S provides collision detection, while EF-Tune analyses programs and recommends optimal feed rates and cutting conditions.

Notably, a Blum tool measurement system works in tandem with a Renishaw touch sensor.

“We would traditionally use a laser, but with a spot diameter on the laser, manufacturers are limited to the minimum diameter of cutting tool available,” says Plaskitt. “On the Sodick UX450L we use an optical system, which means we can go down to a 0.2 mm diameter cutting tool with absolutely no problem and still measure to a couple of microns. The camera we have on the machine will not only check the form of the cutter but also the run-out. The shrink fit toolholders are good for 2 µm, but we can counteract that by using the camera system.”

He concludes: “This is not your run-of-the-mill machining centre. It sits in the top tier of the machining centre pyramid, supporting high-end medical and mould and die applications, as well as other niche areas that demand high levels of precision.”