Sheet metal storage system upgraded

A long-standing user of materials storage solutions from German firm Kasto Maschinenbau – KWM Weisshaar in Mosbach, Germany – called in the supplier last year (2024) to upgrade the electrical equipment, electronics and software of a 17-year-old Kasto UNIGRIP buffer storage system. A similar service is available in the UK and Irish markets from Kasto’s subsidiary in Leicestershire.

As a sheet metal processing, fabrication and logistics company, KWM Weisshaar processes around 5,000 tonnes per year of steel, stainless steel and aluminium every year. Most customers are located in Germany, Austria and Switzerland, the most significant industry served being rail vehicle construction. The company not only manufactures mechanical components such as roof segments for railcar bodies, but also complete air conditioning units and battery boxes. It has an annual turnover of about 50 million euros and employs around 450 people, approximately 10% of whom are apprentices.

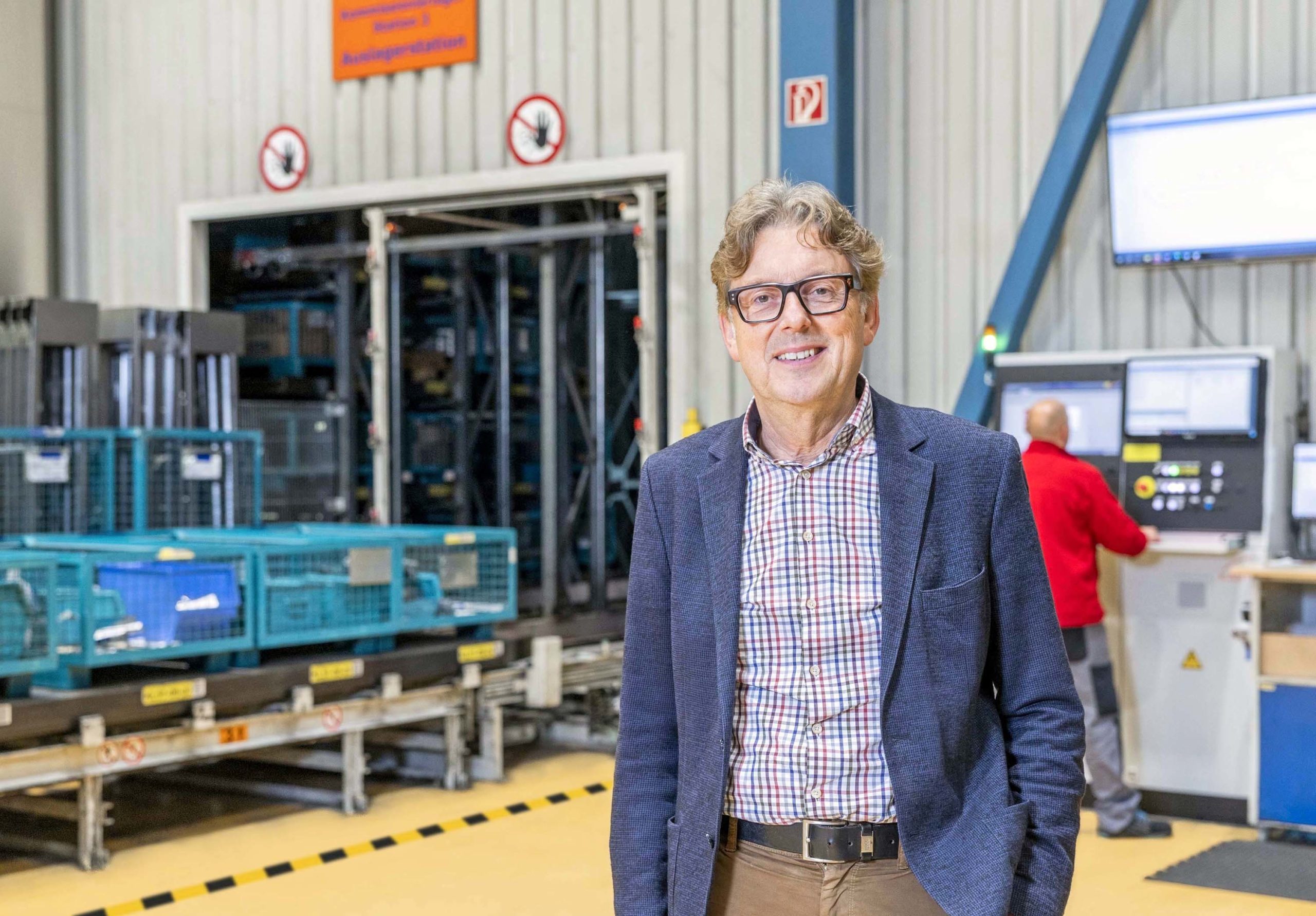

Karl Weisshaar established the company in 1979, but it was not until 2007 that a new, multi-story production facility was constructed. His son Jörg, who holds a degree is in industrial engineering, says: “At the time, we reorganised our entire material flow and invested in modern production machinery and efficient warehousing technology. Back then, my father was looking for a manufacturer that could supply not only the order picking storage system for final assembly, but also the bulk material warehousing. Working with the same partner for both storage systems was key for us.”

Another factor played a significant role in the decision-making. The supplier needed to implement the refurbishment project quickly, with minimal impact on production, as the sheet metal processing firm was reorganising its material flow while the business was fully operational.

Since 2007, KWM Weisshaar has been using the Kasto UNIGRIP buffer store with three output stations, along with a Kasto UNILINE with 13 output stations for raw material storage. The former has 682 spaces that can accommodate wire mesh containers ranging from 530 to 2,000 mm in height. Each has a maximum payload of 3 tonnes. The output stations are equipped with sensors that monitor the dimensions of the load and halt operation if the specifications are exceeded.

Holger Guddat, in charge of maintenance and repair at KWM Weisshaar, says: “Over the years, we’ve encountered only a very few storage system-related issues. The technology operates flawlessly, which is crucial to us, since any downtime would stop our entire production. With operational uptime in mind, we ensure that the storage systems are regularly serviced. If the unexpected does occur, we can rely on Kasto for prompt assistance. When we report a fault, a service technician usually arrives the same day and rectifies it almost always within a few hours.”

The overhaul started at the beginning of January 2024, at which time 10 Kasto service technicians were deployed to replace all the electrical components, including the switch cabinets, control panels and drive controllers. New Profinet bus technology was installed and the energy supply to the overhead gantry crane was upgraded.

Kasto technicians also modified safety equipment, such as the emergency stop, safety door, light barriers, and the limit switches for the hoisting gear and longitudinal travel, so they meet current specifications. In addition, the warehouse management system software KASTOlvr was swapped for the up to date KASTOlogic.

A lot of work needed to be done, but after seven working days it had been completed on schedule. During the following three-day commissioning, Kasto personnel trained KWM Weisshaar employees on using the new technology, after which the storage system was fully operational over two shifts per day. An added advantage is that the KASTOlogic can be interfaced with the proALPHA enterprise resource planning system in use at Mosbach, ensuring seamless data transfer.

Karl Weisshaar concludes: “Our experience with the retrofit was very positive. The project was well organised and Kasto did an excellent job of the implementation. With our upgraded UNIGRIP, we are well equipped for the next 17 years.”