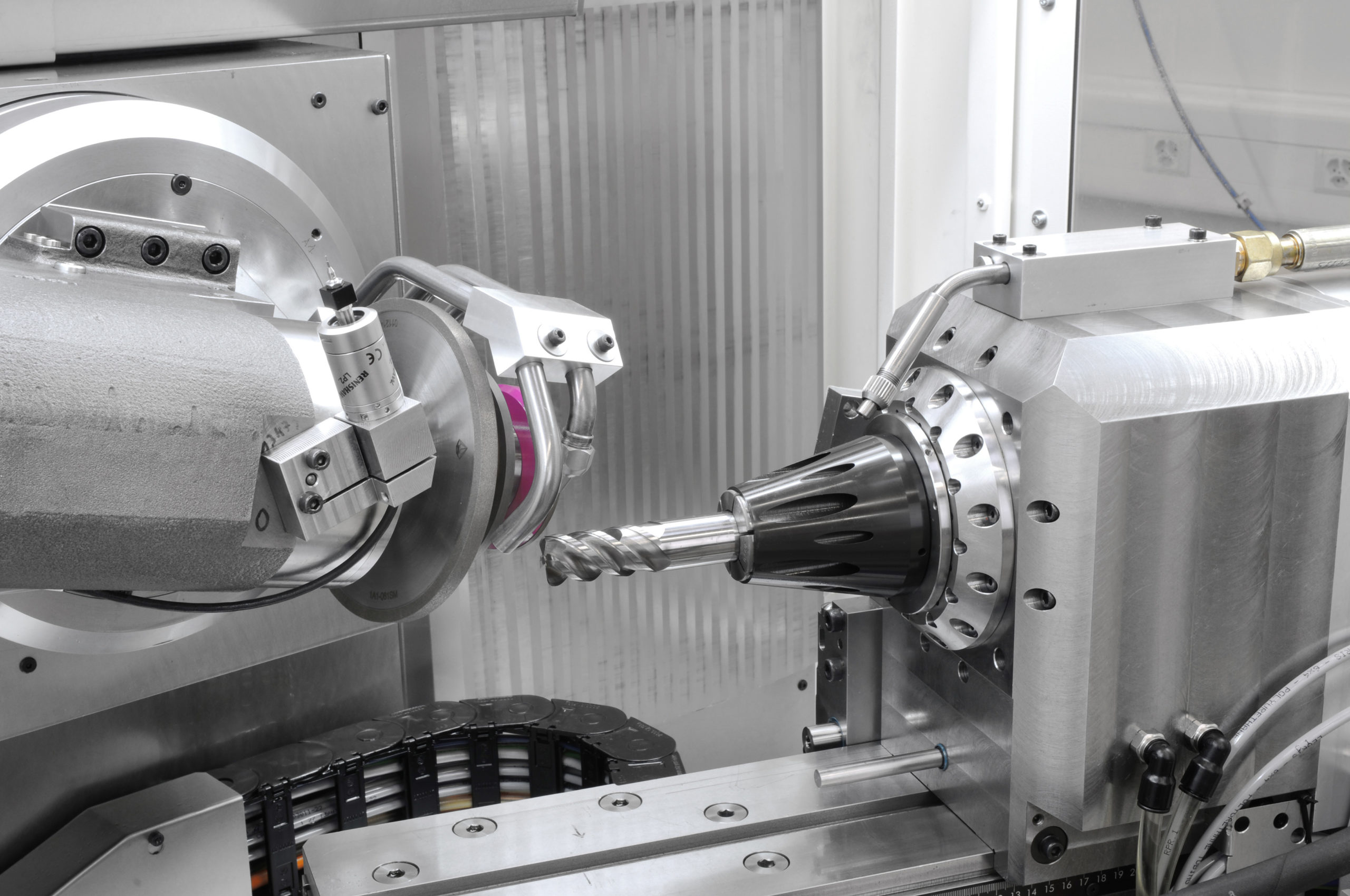

Rollomatic GrindSmart 830XW six-axis tool grinder suits larger diameter cutters

Rollomatic, represented in the UK and Ireland by Advanced Grinding Solutions (AGS), says that the combination of hydrostatic guideway technology and linear motors found on the top-of-the-range six-axis Rollomatic 830XW tool grinder delivers precision and efficiency in the production of larger diameter cutters. Notably, the use of the same coolant oil for the hydrostatic guides and grinding spindle, which is the same coolant used during grinding, ensures high thermal stability during set-up and production.

Rollomatic’s vision of ‘smart autonomous grinding’ is to provide end users with a fully autonomous machine capable of managing production with very little human intervention. A part of this ambitious concept is the ability of the GrindSmart 830XW to manage the offsets and manufacture the first parts within specification. Further items are included to achieve unattended production over several days within very tight tolerances as the machine interacts with optional external robotic and automation systems. Smart autonomous grinding from Rollomatic also includes machine connectivity and communication exchange systems, enabling interaction with measuring machines, laser etching machines and more.

Freedom of movement

The GrindSmart 830XW boasts a six-axis kinematic system for freedom of movement during machining on both sides via a total rotation angle of 240°. As a result, both right-hand and left-hand tools can be ground with the same wheel pack.

The hydrostatic system offers a high damping effect, resulting in smooth surface finish and extended grinding wheel life. The mirror-like surface finish, which is especially important for cutter flutes, is improved by around 20% on the GrindSmart 830XW compared with machines that do not employ hydrostatic technology, reports AGS. The six-axis arrangement allows the grinding point to remain constant on tools such as ball-nose cutters, those with full radii and special form tools. This capability enhances cutting tool geometry, including a radius shape accuracy of under 0.003 mm, in comparison with machines that only grind in five CNC axes.

The machine can manage offsets, achieve tight tolerances and interact with its own internally mounted FANUC-based robotic automation system, which has a capacity of 10 workpiece pallets with an auto-load capacity of up to 4,500 cutting tools.

Smart set-up assistant

The GrindSmart 830XW also includes a smart set-up assistant, which helps users achieve the first ground tool within all tolerances. The program generates a grinding path for each operation required on the blank. After completion of these grinding operations, touch probe measurements define the grinding wheel corrections before making the first tool. The machine then grinds the blank to the geometry programmed by the operator, taking into account the corrections required. In-process measurement functions then take place periodically by either the probe or laser measuring system to guarantee that tools remain within defined tolerances throughout production.

With its compact 15-station wheel and nozzle changer, which has capacity for up to 60 grinding wheels, the GrindSmart 830XW offers an arbor‐to‐arbor change time of only 5 seconds.

Additional options available include Rollomatic’s smart shank guide, which guarantees concentricity of under 0.002 mm for every clamping. It saves time and boosts productivity, as it is no longer necessary to probe tools for runout automatically during set up. Another option is Rollomatic’s smart steady rest, a precision steady rest for drills and other long tools. It provides stability for the grinding process and allows the use of faster feed rates.

Although designed for manufacturing larger diameter tools, the GrindSmart 830XW can manufacture tools from 1 to 32 mm in diameter with a maximum overall length of up to 300 mm. The grinding spindle’s synchronous motor has a peak power of 14 kW with a rotational speed of up to 12,000 rpm. As with all Rollomatic tool grinders, the machine comes with all available cutting tool software free of charge, with free lifetime updates. Users can also benefit from Rollomatic’s unlimited hours three-year parts and labour warranty as standard.