Revolutionising Motorhome Manufacturing

Auto-Trail V.R. Ltd, a distinguished British motorhome and campervan manufacturer since 1982, has come a long way from its origins as a caravan repair business. Today, it stands as a market leader in high-quality leisure vehicles, renowned for its customisable, luxury motorhomes. The key to their continued success? Embracing cutting-edge technology.

Auto-Trail’s journey began as a modest caravan repair service, but it wasn’t long before the company responded to the growing demand for bespoke, high-end motorhomes. Over the decades, Auto-Trail introduced notable models like the Cheyenne range in the 1990s and the A-Class motorhome in 2006. These milestones cemented its reputation for innovation and excellence.

Auto-Trail’s vehicles are more than just motorhomes—they are gateways to adventure. Each vehicle is meticulously designed to seamlessly integrate into the lifestyle of adventurers, making every journey memorable. What truly sets Auto-Trail apart is its commitment to personalisation, offering an extensive range of customization options to meet and exceed customer expectations.

Embracing Advanced Technology

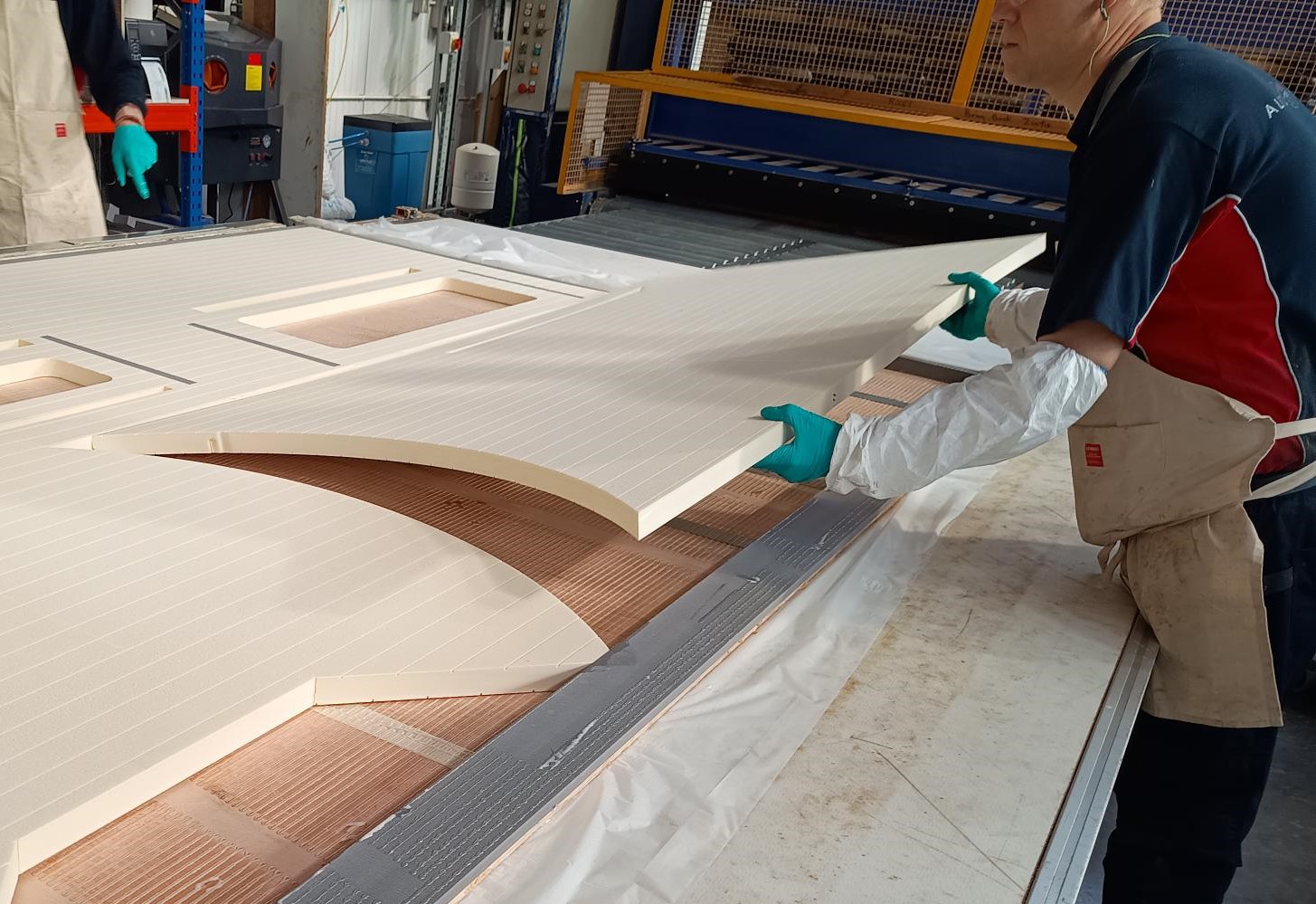

Facing the imminent retirement of a skilled employee and the limitations of manual production methods, Auto-Trail decided it was time to automate. “The limitations of hand-cutting and the need for more precise and efficient methods were clear,” explains Design Engineer Paul Spivey. After evaluating various technologies, Auto-Trail chose the AXYZ INFINITE 4022 1C2Z ATC CNC Router. Its flexibility, multi-change router head, and suitability for their manufacturing environment made it the ideal choice.

The introduction of AXYZ machines revolutionised Auto-Trail’s production, particularly in handling insulation material for pressed panels. Manual cutting was replaced with precise CNC routing, allowing for better shaping, reduced component count per panel, and improved fit. This change led to significant reductions in waste, printing, paper, and transport costs. Additionally, the machines facilitated the production of customized parts, enhancing efficiency and material utilization.

Quality and Innovation

Integrating AXYZ technology not only optimized production but also maintained high-quality standards. The precision of CNC routing ensured each part met strict quality requirements, crucial for the reliability and performance of Auto-Trail’s motorhomes. This technological advancement resulted in significant cost savings and quality enhancements, reinforcing Auto-Trail’s reputation for excellence and customer satisfaction.

The shift to automation was positively received by Auto-Trail employees, who viewed it as an opportunity for professional growth. Automation empowered them to adapt to new technologies and take on enhanced roles within the organization. As manual tasks were automated, employees could focus on innovation, collaboration, and continuous improvement. To ensure smooth operation, Auto-Trail invested in training, equipping workers with the skills needed to operate the new technology efficiently.

Integrating AXYZ machines wasn’t without its challenges. Auto-Trail faced spatial constraints and the need for process optimization. However, through meticulous planning, testing, and collaborative problem-solving, these obstacles were overcome. Specialized equipment and adjustments to bills of materials, cut lists, and drawings ensured a smooth transition to automated production.

Auto-Trail maintains its AXYZ machines with regular onsite engineer checks and a maintenance contract with AXYZ. Looking to the future, the company plans to further integrate automation into its processes, continuously seeking opportunities to optimize production and drive innovation.

Looking Ahead

Auto-Trail V.R. Ltd remains committed to expanding the use of automated technologies across its production areas, aiming for greater efficiency and productivity. The implementation of AXYZ machines has marked a significant shift in Auto-Trail’s manufacturing approach, allowing for custom-shaped parts, optimized component counts, and improved panel construction.

The adoption of AXYZ CNC routers has significantly transformed Auto-Trail’s manufacturing landscape. By automating key production processes, Auto-Trail has enhanced operational efficiency, reduced costs, and maintained high-quality standards. This successful integration of AXYZ technology underscores Auto-Trail’s commitment to innovation and customer satisfaction, setting a new benchmark in the motorhome manufacturing industry.