Renishaw to showcase extended range of shop-floor inspection solutions at EMO 2025

Renishaw, a specialist in measuring and manufacturing systems, will be showcasing an extended range of products at EMO 2025 (Hanover, 22-26 September) that is designed to provide fast, automated and flexible inspection on the shop floor. Visitors to the stand (hall 5, stand D06) will see the new Equator-X 500 dual-method gauge alongside its Agility shop floor multi-sensor CMM system.

The Equator-X gauge enables manufacturers around the world to select the optimum inspection method, Absolute or Compare, for their process challenge – effectively deploying two systems in one.

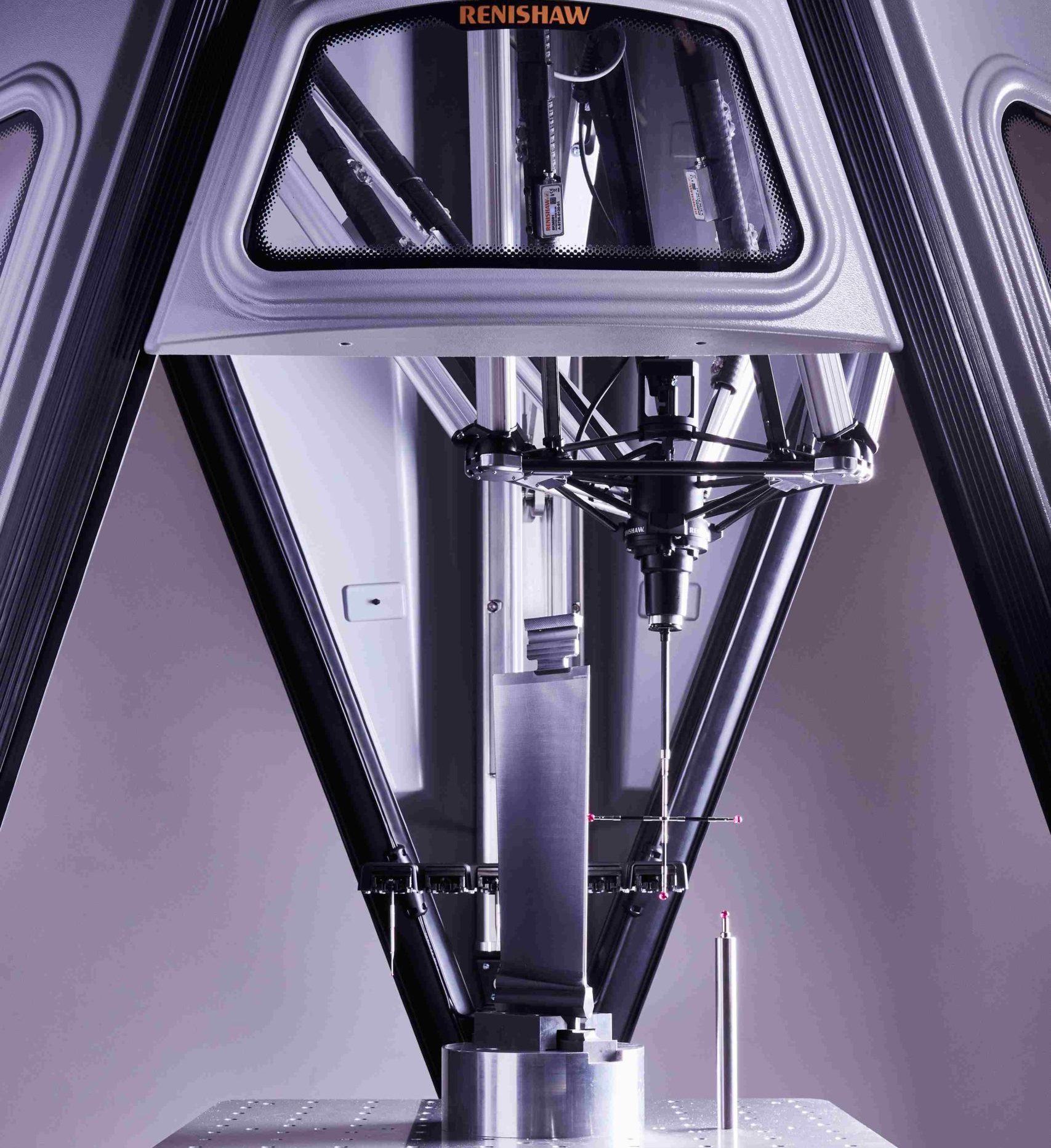

In Absolute mode, the Equator-X system measures parts at scanning speeds of up to 250 mm/s, improving inspection capacity and throughput for manufacturers of small-to-medium batch sizes and high part variety. This mode is particularly useful for first-off verification next to the machine or even at-line 100% inspection.

In Compare mode, the Equator-X system delivers a high scanning speed of up to 500 mm/s, making it suitable for inspecting large batches of the same component when cycle time is a priority. It also provides a high-speed measurement option where varying thermal environments present a challenge.

Key benefits of the system include: increased throughput, with high-speed measurement that increases inspection capacity; fully traceable in-process verification of parts on the shop floor; continuous validation of production processes; and the flexibility to select the optimal measurement method for each application with a single device.

The Equator-X 500 gauge is a dynamically stiff hexapod structure with independent drive and metrology frames. High-speed motion is achieved without compromising metrology thanks to design features such as carbon-fibre metrology struts, linear motor drives and the SP25M scanning probe.

User can deploy the system as a stand-alone shop-floor device or integrated within a fully automated cell, offering flexibility to adapt to evolving demands and variable shop-floor conditions.

The standard software platform for the new Equator-X 500 system features an intuitive and feature-rich operator interface coupled with Renishaw’s latest Modus IM Equator metrology software applications. This comprehensive suite of software tools delivers convenience and robust performance for programming, reporting and operation, simplifying complex tasks and enhancing user experience.

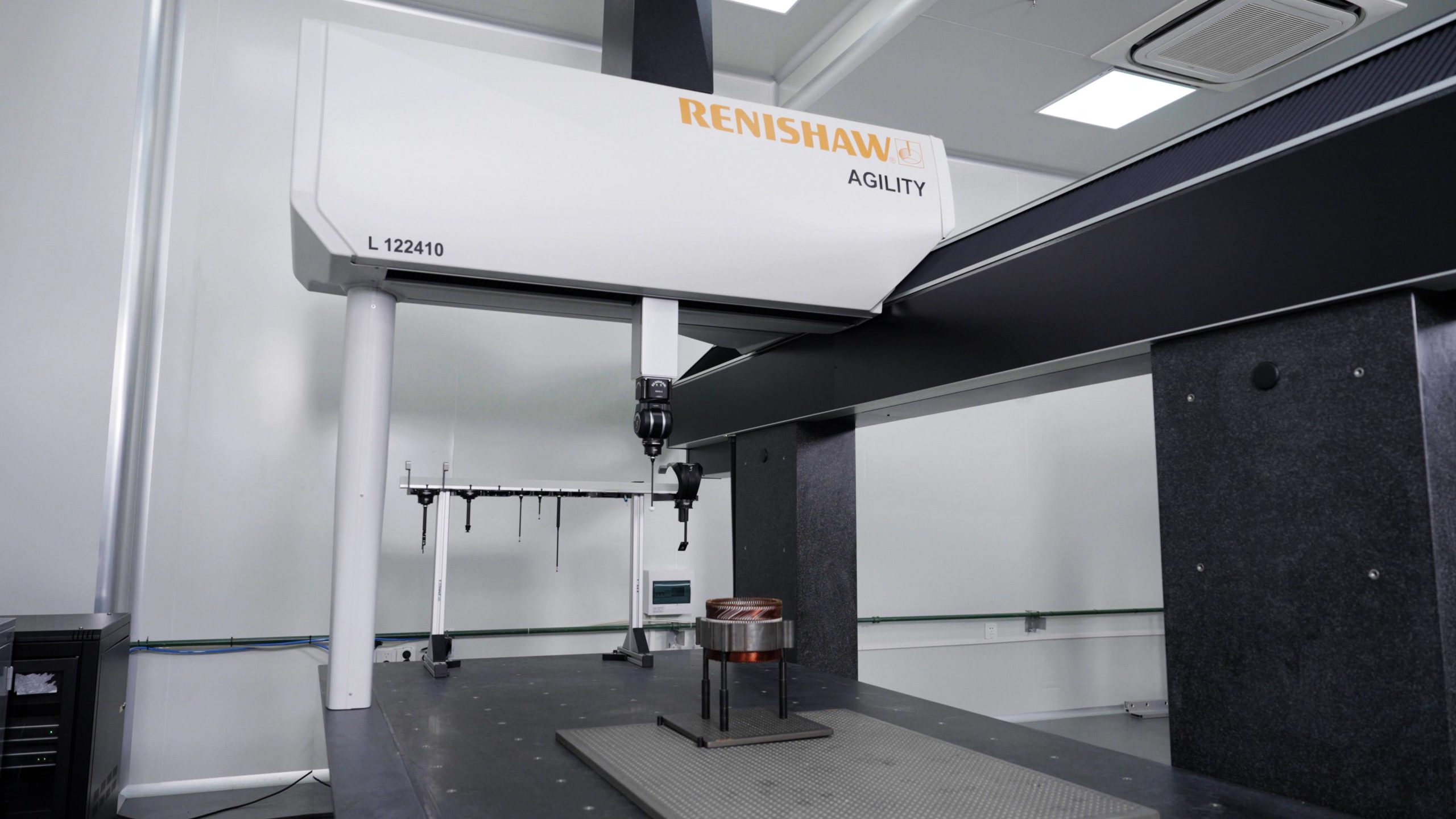

Also on display, the range of Agility CMMs has been designed for speed and accuracy. Optimised for Renishaw’s Revo five-axis multi-sensor system, the established range of Agility CMMs also includes machines for the measurement lab, offering high-throughput platforms capable of using any one of the seven dedicated Revo sensors.

Renishaw says its Agility S shop-floor CMMs provide an accurate and robust solution for inspecting parts in a production environment where clean air and temperature control cannot be guaranteed. Available with working volumes ranging from 700 × 900 × 600 mm up to 1600 × 2400 × 1200 mm (X × Y × Z), some variants offer a raised working volume to accommodate pallet loading systems or rotary tables. All shop-floor models feature elevated Y-axis guideways for further stability and protection from airborne contaminants.

Agility L machines, designed for the metrology lab, are specified for a temperature range of 18-22°C, providing high-performance, multi-sensor five-axis measurement in cleanrooms. The single-sided raised Y-axis design with an outrigger leg expands accessibility for manual part loading when automation is not required. Agility L frames are available with working volumes ranging from 500 × 500 × 500 mm up to the new and largest 2000 × 3000 × 1600 mm.

The Equator gauging products and Agility CMMs are compatible with Renishaw Central: a manufacturing data platform which enables CNC connectivity and closed-loop process control on the shop floor. Renishaw Central uses measurement data to identify deviations and automatically send correction updates to the appropriate manufacturing machines.