Renishaw to showcase advanced technologies at Southern Manufacturing & Electronics 2026

Renishaw will be exhibiting at Southern Manufacturing & Electronics 2026 on 3-5 February at the Farnborough International Exhibition Centre. Visitors can find the company on stand C250, where it will present a range of metrology and manufacturing solutions, including the UK debut of the Equator-X™ dual-method gauge.

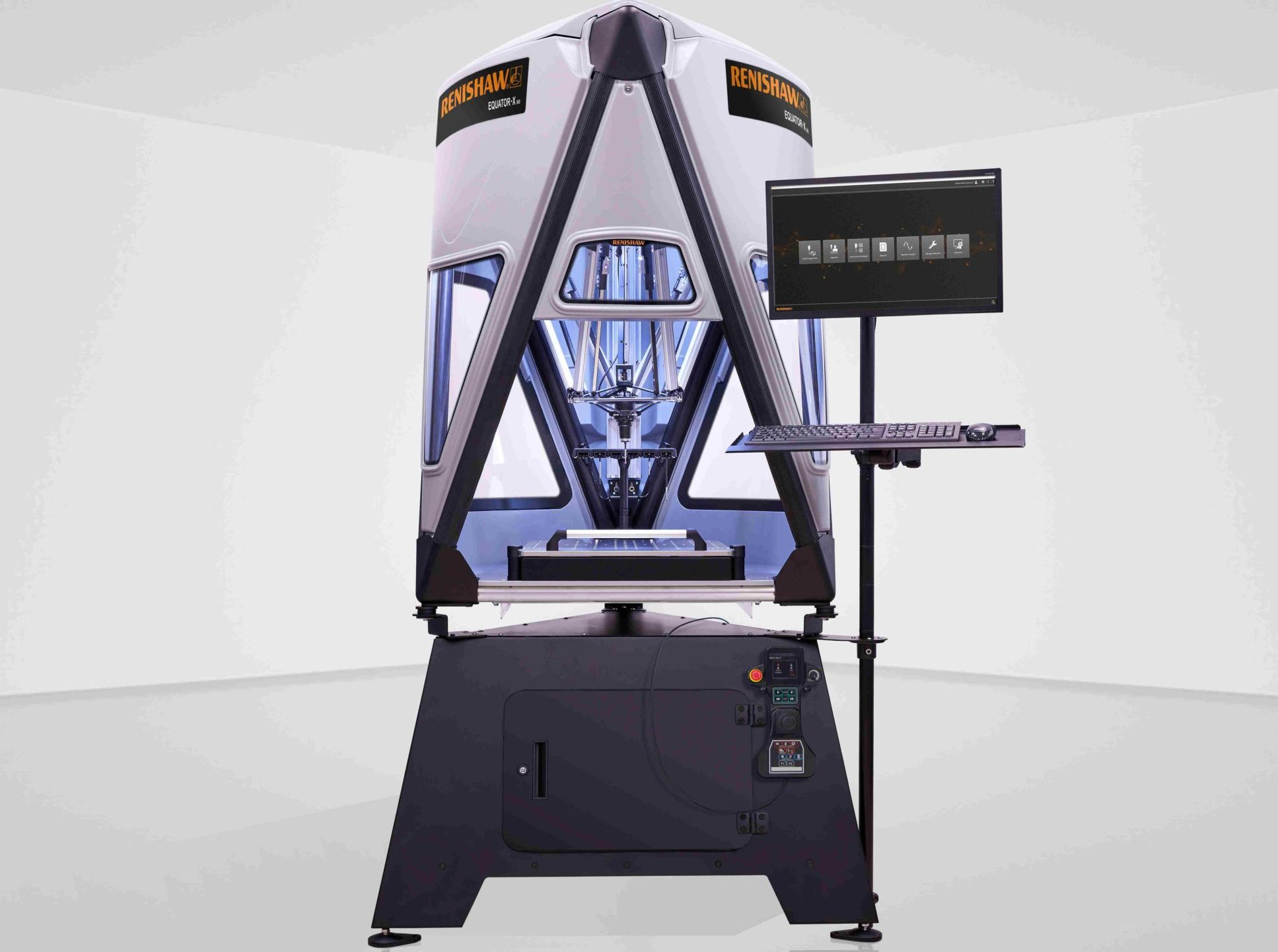

The Equator-X™ system (pictured) will take centre stage on Renishaw’s stand, with live demonstrations featuring an aerospace component. The demonstrations will illustrate the system’s ability to measure parts directly on the shop floor and provide immediate production feedback.

“Southern Manufacturing & Electronics will be the first UK exhibition to feature our Equator-X™ dual-method gauge,” says Michael Duffield, UK General Manager at Renishaw. “The Equator-X system enables measurement of parts as close to the source of production as possible, providing instant feedback on component conformance. Connection to the machine tool allows precise process control by updating tool offsets, maximising yield and profitability.”

Visitors will also discover how Renishaw Central delivers real-time insights into production performance and explore the new MODUS™ IM Equator Programmer software. This intuitive, CAD-based programming solution enables faster offline program creation, automatically importing GD&T data from CAD, with full simulation. Certified algorithms ensure accurate feature measurement, feature construction and precise part alignment.

Elsewhere on the stand, attendees can explore Renishaw’s rotary and linear encoder solutions, which deliver high-precision position feedback to enhance machine accuracy. Built with a zero-wear, non-contact design, the encoders feature incremental or absolute scales, with read-heads providing low-noise position signals for superior motion control in demanding industrial applications. Renishaw will also display its range of FORTiS™ enclosed linear encoders (pictured), designed for robust, high-performance measurement, with vibration resistance, in harsh environments such as machine tools.

In addition, the stand will highlight additive manufacturing (AM) systems, demonstrating Renishaw’s capabilities in precision metal 3D printing and post-processing measurement. Also on display will be the company’s machine tool probes, which support accurate, efficient and repeatable machining processes.