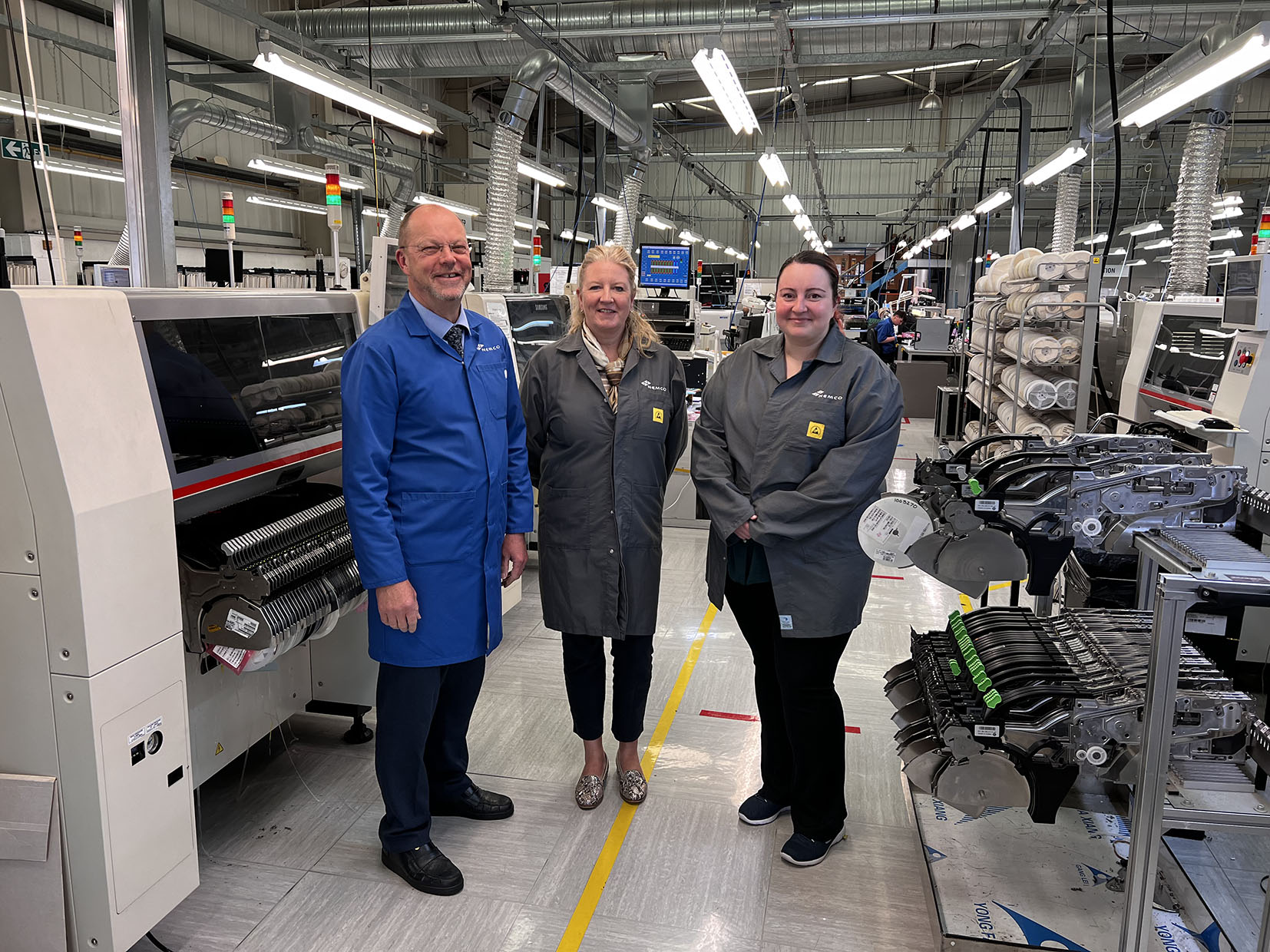

Record volumes for Nemco as it marks 10-year anniversary of supporting Fortress

Helping ease global supply chain disruption has seen Nemco extend its working relationship with one of the world’s leading designers and manufacturers of customised safety equipment.

The Stevenage-based contract electronics specialist is celebrating 10 years of supplying Fortress with assembled PCBs for a growing range of products that keep hundreds of thousands of people safe every day.

What started as prototype support and a few thousand assembled PCBs has now grown to volumes in excess of 90,000 per year and covering more than 50 different board variations across various solutions, including mGard trapped key, proNet, amgard ethernet enabled interlock, Atom and tGard configurable interlocks.

The business will be worth £2m per year for Nemco, which is on course to hit its best-ever sales year.

“We work really hard to build strategic relationships with our customers – it’s about a lot more than just supplying boards,” explained Bob Parker, Operations Director of Nemco.

“Our partnership with Fortress is the perfect example of our approach. We work with its design team on new product introductions and then offer technical advice on the most efficient Design for Manufacturing (DfM) process.”

He continued: “This is a real two-way conversation and involves lots of dialogue and collaboration. We’ve also got the capabilities in Stevenage to do prototyping work, so we can support the customer with quick turnaround assembled PCBs that speed up the development stage.”

There has been a lot of talk about disruption in the electronics supply chain and this is something Nemco has helped Fortress overcome through flexibility of supply, just-in-time production and providing alternative components to negate shortages across the sector.

This has ensured that many Fortress products can be supplied to customers in just two weeks, thanks to forward scheduling and advancing ordering.

Michael Trice, Design Manager at Fortress, went on to add: “Nemco boards are in all but two of our product ranges and that’s testament to the quality of the components supplied.

“We know the PCBs will work at the first time of asking and this means production and assembly at our factory in Wolverhampton is not held up and we can meet urgent client requirements. It’s a relationship that is going from strength to strength as we continue our collaborative new design with Nemco.”

Karen Stead, Head of Supply Chain at Fortress, provided her insight: “We are looking at another year of sustained growth by staying true to our mission of ‘saving lives by providing the best safety solutions’.

“To achieve this we need to have really strong relationships with our suppliers in place and the way we work with Nemco is a fantastic blueprint for us to use. There’s complete transparency on both sides and the understanding we have built up means we can pull off volumes at relatively short notice.”

Nemco, which was formed in 1985 by Dave Pearce and currently employs 130 people at its 60,000 sq ft Wedgwood Way facility, has identified significant opportunities in the automotive, aerospace, renewable energy and EV sectors and is planning to make significant inroads in the years ahead.

The company has made several strategic appointments in recent months and also joined the Manufacturing Assembly Network (MAN), a collective of seven sub-contract manufacturers and an engineering design agency.

This will see it tap into best practice, learning and development opportunities and, importantly, access to new opportunities that will arise from being part of the group.