Rapid Fusion aims for transatlantic expansion with first US deal

Rapid Fusion is looking to break into America after signing a new reseller agreement with a US additive manufacturing specialist. The Exeter-based business, which employs 10 people at its state-of-the-art Skypark demonstration centre, has joined forces with Phoenix Analysis and Design Technologies (PADT) to sell its robotic additive manufacturing systems to customers in the aerospace and defence sectors.

Bosses at the technology expert believe there are almost £2 million worth of opportunities to be enjoyed in the first year across the western half of the country and have earmarked its Apollo, Zeus and Medusa solutions as offering significant time and cost savings compared to existing models.

The company will initially target PADT’s existing client base, whilst leveraging the US firm’s technical knowledge, manufacturing networks and 30-year track record to make inroads into a market that is estimated to be worth $619.3 million globally by 2030.

Jake Hand, Managing Director at Rapid Fusion, says: “We’ve had significant success disrupting the large format additive manufacturing (LAFM) arena in the UK and Europe, and felt it was time to push into the US. We needed to find the right partner who not only understood our values and our products but also had immediate access to clients who would benefit from our solutions. Initial conversations with PADT founder Rey Chu got us really excited, and we’re delighted to sign the deal that makes the company our first US reseller.

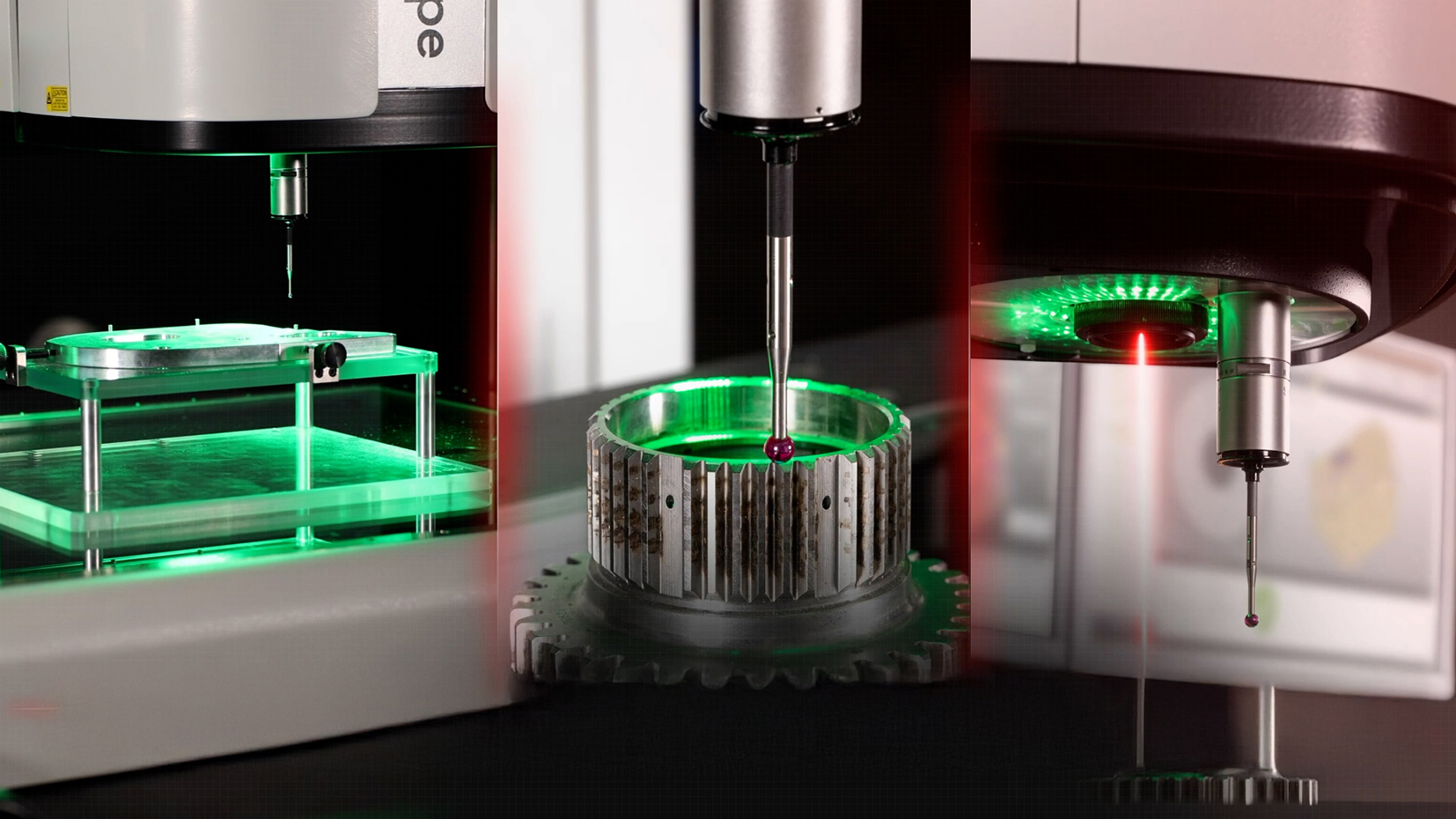

He continues: “PADT will have access to our full portfolio, including Apollo (a full turnkey 3D robotic printer), Zeus (a 3D printing robot that incorporates a unique CNC milling capability) and Medusa. The latter is a real LFAM gem and is three times faster than conventional machines, twice as accurate, and promises to reduce training and maintenance costs by 30%.”

PADT has already committed to recruiting and training up a dedicated Rapid Fusion sales specialist, with the longer-term plan being to host several of the firm’s robots at its headquarters at Arizona State University Research Park in Tempe. It will use its business-to-business marketing and sales function to communicate with prospective customers, initially in aerospace and defence and then moving into automotive, construction and medical.

Interested parties will engage in an initial needs discovery conversation that will proceed to an application analysis and pilot proposal. Once agreed, the project will be executed with the goal of building a business case and ROI justification using jointly defined success metrics, employing actual customer data.

Based on the findings of the pilot, a commercial proposal will then be developed for a production system purchase, system implementation, training and post-sale support.

“Rapid Fusion’s pellet extrusion and robotic arm-based 3D printing systems offer a complementary and disruptive alternative to our current additive manufacturing offerings, enabling new applications in aerospace, construction, motor vehicles, and tooling,” says Rey. “With a 100,000-strong marketplace on the West coast alone there is so much potential to disrupt the US marketplace, and we’re looking forward to accelerating the UK firm’s presence here. The key will be getting the first customers on board and then we have a fantastic test case to entice more companies to adopt the technology.”

Jake concludes: “The US is the largest country globally for additive manufacturing and a strategic part of our expansion plans. We conservatively forecast around £2 million of revenue in the first 12 months and then, over time, for it to grow to become our largest territory.”