R E Thompson invests in new Flexible Manufacturing System.

R E Thompson has continued the long relationship with Fastems by investing in a new Flexible Manufacturing System and modernizing their existing systems.

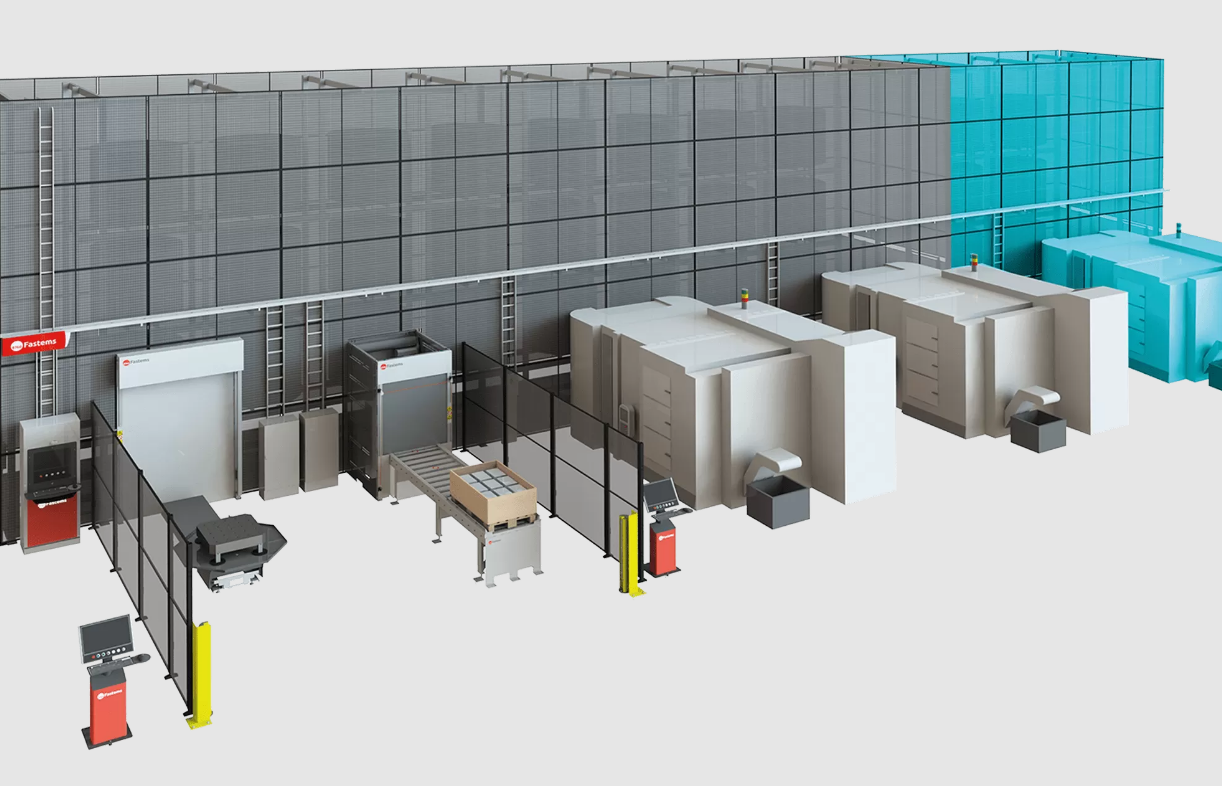

This is a pallet-based system for automating machining Centres, enabling high productivity regardless of the Workpiece variety. Automation enables higher spindle utilisation per machine, ensures constant quality and allows bottleneck resources to be shared. When stand-alone machines run an average of 2,000 out of 8,760 hours annually, machines in an FMS run 6,000 hours on average.

As well as having a new FMS, R E Thompson has reinvested in 15-year-old equipment to upgrade to the latest Fastems software; this will reinject life into old equipment sustainably.

All four Fastems systems at R E Thompson will now run on the latest Fastems flagship software – manufacturing management software (MMS) 8. This will ensure all systems are connected to the R E Thompson network with the highest level of Industry 4.0 connectivity available. MMS is the industry’s most advanced production planning and execution software. MMS is always one step ahead by automatically calculating the optimized production workflow and necessary resources-based orders. MMS automatically adapts to changes in the daily production schedule and displays information to maintain the production output.