Precision in flight: Evolving machining solutions for aerospace manufacturers

The aerospace sector operates at the intersection of advanced technological demands and stringent cost-efficiency targets. With major aircraft manufacturers forecasting the production of over 42,000 new aircraft over the next two decades, the demand for precision machining tools continues to rise.

Aircraft construction is an intricate process involving a wide range of materials, each presenting distinct machining challenges. Aluminium alloys remain dominant, accounting for around 60% of structural components. Titanium and advanced composites also play essential roles in critical structural and performance-focused applications.

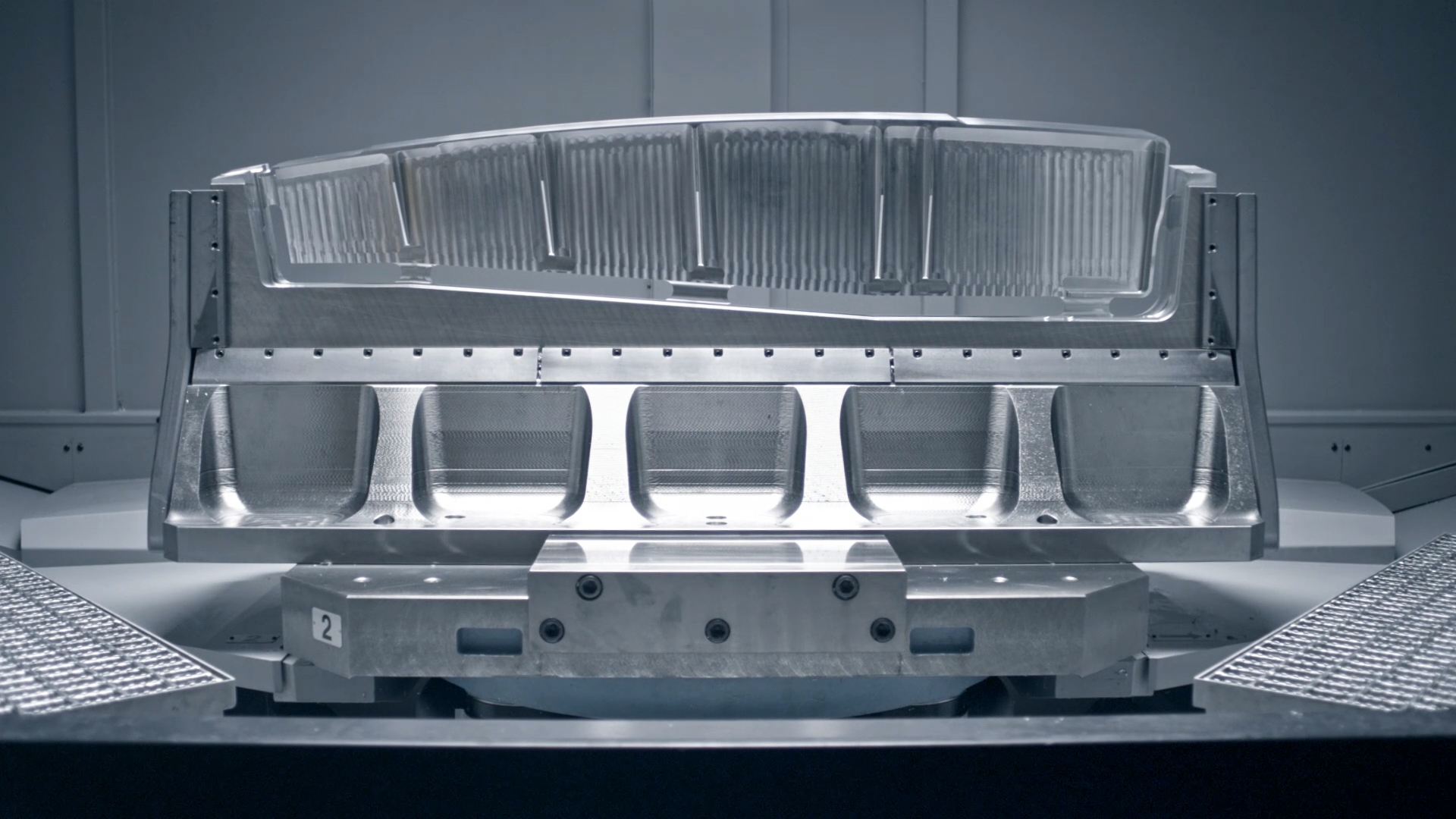

Aluminium alloys from the 2xxx, 6xxx and 7xxx series combine low weight with robust structural integrity. Machining these alloys requires methods that balance material removal, surface finish and dimensional accuracy. High-speed cutting technologies have become central to meeting such requirements. Modern milling cutters, such as Walter’s M2131 and M2331 systems, have been developed specifically to address these challenges. These tools offer insert sizes for depths of cut of 15 or 20 mm and enable chip removal rates of up to 11 l/min.

The cutters deliver smooth surfaces even in pre-finishing operations. Their dense PVD coating ensures high stability and minimises cutting edge build-up. The insert seat design secures the insert against the centrifugal forces encountered in HSC applications. Additionally, internal coolant channels direct fluid to the cutting edge, extending tool life and supporting efficient chip evacuation.

While aluminium alloys are common in fuselages and wings, titanium alloys such as TiAl6V4 and Ti5553 are used in components that demand exceptional rigidity, including landing gear and flap tracks. Titanium’s low thermal conductivity and high strength present significant machining difficulties, often resulting in rapid tool wear and long cycle times.

Reducing machining time in titanium components provides manufacturers with clear competitive advantages. Tools such as the Walter BLAXX M3255 helical milling cutter are designed to address these challenges. The cutter’s geometry enables multiple teeth to engage the workpiece simultaneously, while the positive insert geometry supports smooth cutting and reduces resistance. This combination allows higher metal removal rates and faster machining.

Effective heat management remains critical when machining titanium. The M3255 cutter features optimised chip clearance and coolant delivery, ensuring chips are reliably evacuated even at higher speeds. Its tangentially positioned indexable inserts increase cutting power and allow machining of forged parts where hardened surface layers can damage conventional cutting edges. Used primarily in rough machining, this solution has been shown to reduce titanium machining times by approximately 22% and double tool life due to its insert geometry and chip evacuation capabilities.

Machining heat-resistant superalloys (HRSA), such as nickel-based alloys used in engine components, adds further complexity. Conventional carbide milling cutters typically achieve cutting speeds around 50 m/min. In contrast, ceramic cutting tools can operate at speeds approaching 1,000 m/min, significantly reducing cycle times.

SiAlON ceramics are particularly suited to HRSA machining because they are less prone to temperature fluctuations than whisker-reinforced ceramics. In milling operations, where cutting edges are repeatedly heated and cooled, thermal shock can cause cracks and fractures. Dry machining with ceramic cutters is therefore recommended to avoid these effects and to reduce lubricant use.

One of the most demanding HRSA applications is the production of blisks – bladed disks made from nickel-based alloys. Machining each blade pocket with conventional tooling can take more than 30 minutes. Ceramic milling cutters with high-feed geometries can complete the same operation in about 10 minutes. In heat-resistant alloys with hardness up to 44 HRC and tensile strength of 1,400 N/mm², feed rates of up to 9,500 mm/min can be achieved—performance more commonly associated with aluminium machining.

Solutions such as the Walter MC075 ceramic end mills incorporate SiAlON technology for high temperature resistance. Available in a range of geometries and interfaces, these cutters offer cutting speeds up to 1,000 m/min while supporting consistent performance in superalloy applications.

Alongside advances in cutting tools, the aerospace industry increasingly adopts near-net-shape manufacturing methods. Unlike the automotive sector, where large production volumes are common, aerospace production is characterised by relatively low quantities, even at the largest manufacturers. This has led to the adoption of 3D printing and forging techniques to create components closer to their final form, significantly reducing machining requirements.

Near-net-shape processes can cut material usage by up to 90% and reduce the weight of components by more than 50%. From a machining perspective, these methods help shorten cycle times, lower costs and decrease waste. Nevertheless, 3D-printed parts still require finishing operations to achieve the required surface quality. The layered structure inherent in additive processes often results in rough surfaces and dimensional variation, which must be corrected by milling and grinding. Heat treatment can introduce distortions that also demand additional machining. Support structures generated during printing must be removed to finalise the component.

These requirements ensure that precision cutting tools remain essential to aerospace manufacturing, even as additive processes mature.

Across the sector, tooling innovations have had a measurable impact. In the production of aluminium structural components, one aerospace manufacturer implemented Walter’s M2131 milling cutters to produce wing ribs. The result was a near doubling of material removal rates, reducing machining time by 46% while extending tool life by over a third and lowering the cost per component by 28%.

Similar improvements have been demonstrated in titanium applications. Adopting the Walter BLAXX M3255 cutter in machining Ti5553 landing gear parts achieved cycle time reductions exceeding 20% and doubled tool life, resulting in a 31% decrease in tooling costs.

For superalloy machining, the introduction of the MC075 ceramic milling system reduced machining time per blisk blade pocket from 30 to 10 minutes. Despite higher tool investment, the reduction in cycle time and the increase in throughput resulted in overall machining cost savings of 65%.

As the aerospace sector works towards CO2-neutral operations by 2050, such tooling solutions contribute to sustainability goals. Reducing energy consumption, limiting coolant usage and supporting lightweight design are all areas where modern machining technologies play a role.

Looking ahead, tool manufacturers are increasingly integrating digital capabilities into their solutions. Walter, for example, offers comprehensive tool management systems that incorporate digital twins, AI-supported parameter recommendations and predictive maintenance. These capabilities help manufacturers optimise utilisation rates and improve process reliability.

Advanced cutting tools and digital integration demonstrate that innovation in machining remains central to aerospace manufacturing. With demands for performance, efficiency and sustainability continually increasing, tooling solutions are evolving to support the industry’s ambitions for the decades ahead.