Powdertech’s bespoke masking techniques avoid burr formation during powder coating

During the powder coating of metals, excess powder can gather against the edge of the masking material that creates a rough edge or ‘burr’. Burrs not only present challenges at component assembly, they also affect surface aesthetics. However, Powdertech Surface Science can offer bespoke masking solutions to overcome this issue.

Traditional masking processes can result in burr formation that subsequently requires a deburring process to remove the excess powder. This process adds time and cost to the project, and sometimes damage results to aluminum parts due to the force applied during the deburring operation.

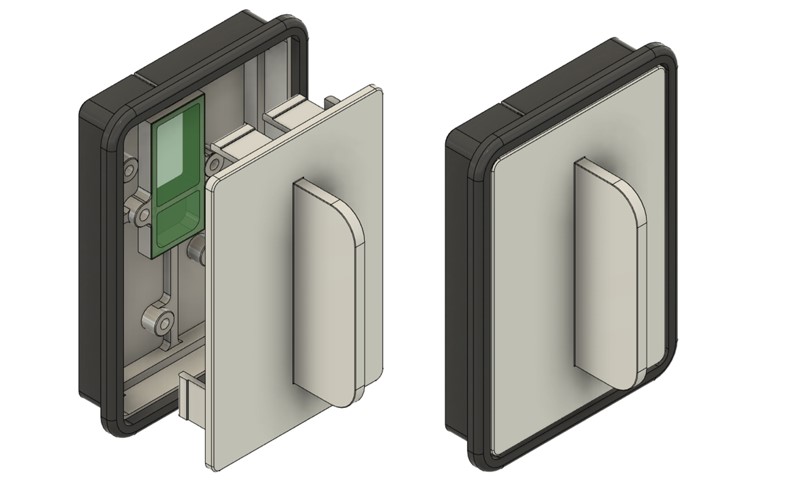

At Powdertech Surface Science, it is important to understand customer specifications and the performance requirements of its components, before offering the correct masking option, including a 3D masking technique for intricate components. To provide a higher level of accuracy in powder coating on low-volume complex parts, it is possible to use 3D masks designed on CAD software. As 3D masks are removed before curing, no burrs form. Through the application of 3D masking, the deburring process is unnecessary, saving time and retaining product quality.

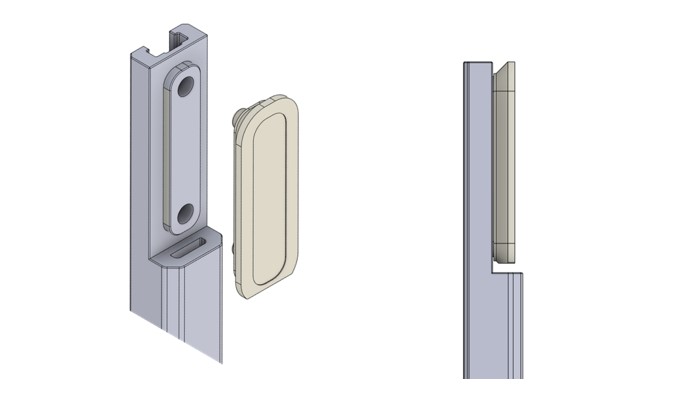

Another option available from Powdertech, mainly for higher volume components, is the use of bespoke bungs. With high-volume parts there is a need to mask areas quickly, while ensuring burrs do not form. The answer lies in the use of flexible high-temperature masks, designed on CAD and made in moulds. The mask design, part orientation and spraying parameters ensures that burrs do not form.

Powdertech Surface Science works in parallel with customer manufacturing processes and production timelines. The company’s engineering team has many decades of experience, both in the generation of finishing specifications,and selecting and designing the right masking scheme. This can be the key to ensuring that machined components meet aesthetic and performance standards, while moving through the finishing process within time and budget.