Pathway to manufacturing resilience

Machinery & Manufacturing visited Mazak’s annual open house in December to see newly introduced machines and hear exclusively from Managing Director Alan Mucklow about market expectations

There were many reasons to visit Yamazaki Mazak’s recent open house at its European Manufacturing Plant and Technology Centre in Worcester. Over 500 visitors from more than 240 companies clearly thought so too. All those passing through the doors got to see 20+ machines on display and take advantage of technology showcases, presentations, expert consultations and guided factory tours – the latter focusing on Mazak’s significant new investment in two fully automated laser cutting machines.

The machine tool sector has seen quite a few challenges lately but, according to Mazak, the key factor is the UK’s manufacturing resilience. Investment is the overriding key to success for the UK’s manufacturing fraternity, whether it’s a new machining centre, turning centre, laser cutter, hybrid machine or automation system.

Breaking new ground

Helping to entice visitors on their investment pathway at the Mazak open house were a number of new-release machines, including the HQR-200/3 NEO turning centre. Equipped with three turrets, two spindles and added tool stations, users enjoy enhanced processing capability for the faster completion of complex parts in a single set up. An optional enlarged (112mm diameter) spindle bore is available for bar work up to 102mm diameter, facilitating the machining of prismatic components from bar material using only a turning centre – work that otherwise would require a machining centre to complete. A redesigned automation device contributes to a 20% reduction in unloading time compared with previous models.

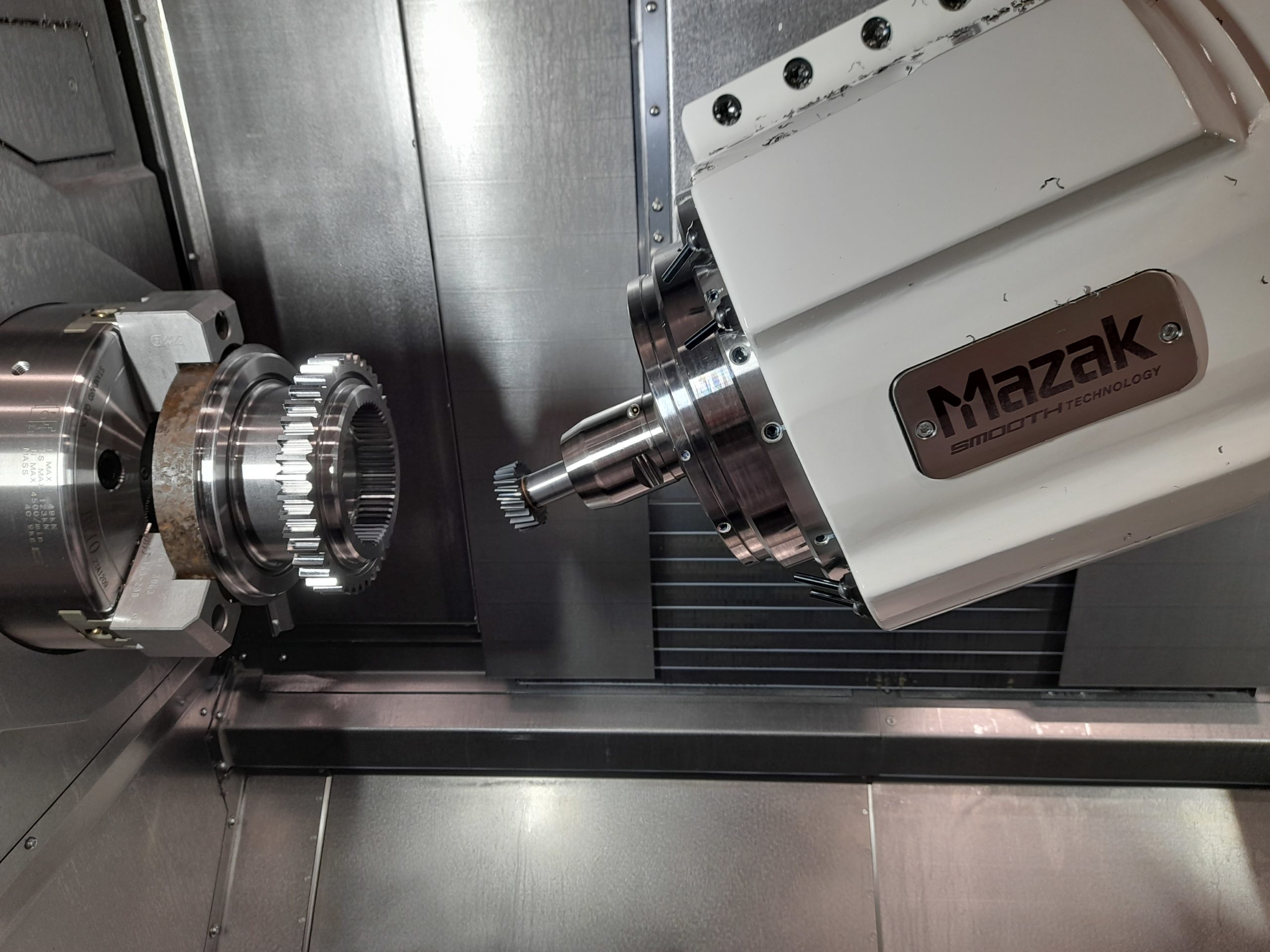

Making its UK exhibition debut was the INTEGREX i-350H ST AG multi-tasking machine with gear cutting and measurement capabilities. The machine was busy at the open house demonstrating a range of specialist tasks such as gear skiving, gear hobbing and gear milling, outlining its ability to reduce production costs, shorten lead times and improve overall efficiency.

Also catching the eye was Mazak’s FSW 460-V hybrid machine with friction stir welding (FSW) capability. This innovative machine is suited to the manufacture of cooling parts for semiconductor equipment, as well as a range of electric vehicle (EV) components like inverter cases, battery cases and motor cases. The high-speed, high-rigidity FSW spindle facilitates joining accuracy via a control function that maintains constant tool thrust force.

From a laser cutting perspective, the open house showcased Mazak’s latest OPTIPLEX 3015 NEO fibre laser. Available in power output from 3 to 20kW, the machine’s beam shaping technology adjusts laser beam power distribution on the workpiece in a controllable and repeatable manner to achieve optimal processing results.

Tour de force

The highlight of the Worcester factory tour was undoubtedly witnessing the complete transformation of Mazak’s laser cutting facility. By replacing the plant’s previous CO2 lasers with two fully automated 6kW OPTIPLEX 3015 NEO 2D fibre laser cutters, Mazak is seeing dramatic reductions in cycle times, idle times and energy consumption. The OPTIPLEX machines cut cladding for machine housings, with support from a double tower automation system to feed sheet material and a robotised Mazak Smart Manufacturing Cell for part sorting.

In an exclusive chat with Machinery & Manufacturing at the open house, Alan Mucklow said: “It’s been a challenging but strange year because we’ve actually performed strongly, based largely on our performance in key sectors like aerospace and defence. The biggest challenge we’ve seen is in the subcontract market, but that’s all about confidence. We still sense a pent-up desire from subcontractors to invest, but the trigger point has moved back. We’ve had a perfect storm of elections here and in the US, alongside the undercurrent of ongoing conflicts and interest rates higher than we’ve seen for some years.”

However, with sentiment beginning to settle and most predicting interest cuts as 2025 ticks along, Alan Mucklow is perceiving a tangible growth in confidence. Seeing over 500 visitors at the Mazak open house certainly seems to support this notion.

“We’re very proud of our annual open house event,” he says. “Sure, it’s a great lead generator, but it’s more about issuing a message that investment is important for success. We practice what we preach in that regard if you look at our factory’s recent investments in grinding, five-axis machining and laser cutting technology. Visitors hopefully leave the open house having learnt something about how they can make their own operations easier, more effective and more profitable.”