OSG UK: Set to drive more growth

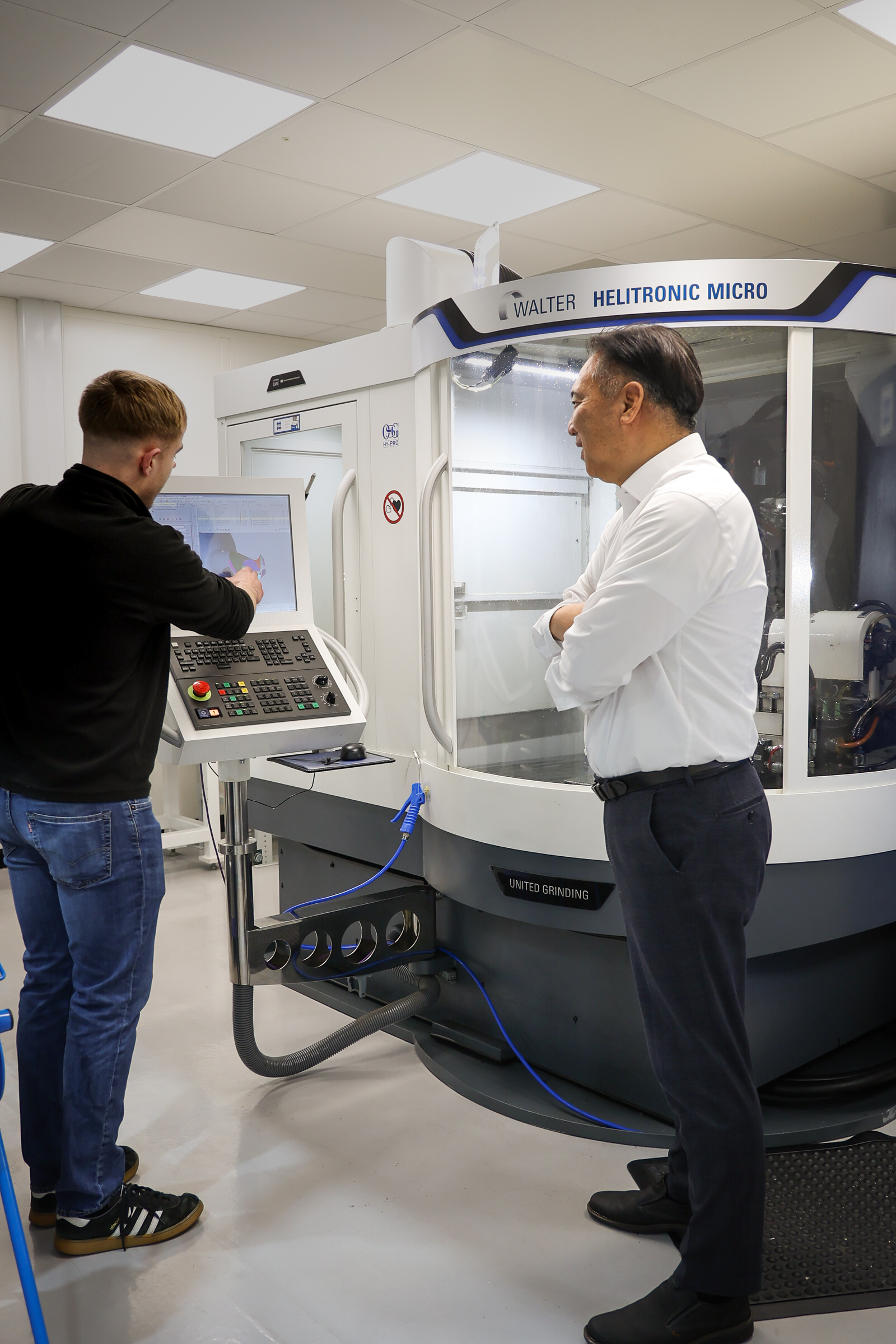

Akinori Fujiyama, the new Managing Director of cutting tool manufacturer OSG UK Ltd, speaks exclusively with Machinery & Manufacturing about his future ambitions for the business

As the figurehead of any company, appointing a new Managing Director is a statement move. For OSG UK, part of Japan-headquartered OSG Corporation – the world’s largest manufacturer of round cutting tools – the appointment of Akinori Fujiyama marks the start of a new chapter in the evolution of this successful and progressive business.

Akinori (Art) Fujiyama joined OSG Corporation’s sales department almost 30 years ago. Following spells at OSG in the USA and Mexico, he returned to Japan for 10 years before taking up the position of Managing Director at OSG Slovakia. Seven years later, he is fulfilling the same role at OSG UK, bringing his wealth of experience to the British cutting tool market.

“I want to lead OSG UK to even higher levels of growth,” he says. “My management style is a little like a Premier League coach. I want to leverage the skills of our many talented employees to create new opportunities.”

Major milestone looms

Art Fujiyama is already looking ahead to a major milestone: the 30th anniversary of OSG UK in 2029. He wants to see what level of gains the business can achieve in the lead up to this landmark moment. “It would be great if we could celebrate by setting out notable achievements,” he says. “We’re currently drawing up a roadmap of ambitions that will lead us towards key targets.”

He continues: “Increasing sales means selecting and focusing on key products. We have plenty of potential to increase our UK market share in both carbide end mills and drills, for instance. These tools – renowned for their Japanese quality and craftsmanship – provide UK machine shops with tangible benefits.”

The focus at OSG UK is always on the customer’s cost per part. As a market differentiator, the company assesses the value its can add to a machine shop’s production process. What is possible: more throughput, more tool life, applying a single tool to more applications?

Current sectors proving strong for OSG UK include aerospace, a core industry for many years, while automotive, medical and general engineering are also performing well. Key among the target markets is micro-machining.

Sustainable future

With an eye on industry trends such as sustainability, OSG UK identifies its eco-friendly Green Tap as an “icon” product of the coming years. The company manufactures the Green Tap series using proprietary methods that reduce CO2 emissions by 35% against standard product production.

“A major goal of OSG globally is to scrutinise our environmental impact,” says Art Fujiyama. “We’re looking at net-zero factories and reducing our carbon footprint worldwide, including here in the UK.”

He adds: “Pivotal to our sustainability efforts and business growth over the next few years will be our global manufacturing sites, all of which operate on kaizen-based continuous improvement principles. Our four UK manufacturing sites, for example, provide us with the potential to look at all markets as potential growth areas. We can tailor solutions in accordance with the specific objectives of customers.”

The flagship UK manufacturing facility is Nuneaton, which produces standard tools, including the HY-PRO performance range, as well as custom tools for every industry and micro-cutters down to 0.3 mm diameter. OSG UK’s Basildon manufacturing plant produces made-to-order taps, while Brighouse-based Brunswick Tooling (owned by OSG) manufactures application-specific tooling with a focus on reamers. Also part of the OSG UK Group is Flatley Engineering in Dublin, which supports both the UK and Ireland markets.

Continuous growth

Business at OSG is going from strength-to-strength. It is already the world’s fourth largest cutting tool manufacturer and closing fast on third place. In 2024, Europe was the company’s largest growth region, indicating OSG’s level of ambition across the continent, including the UK.

“I would like express my sincere thanks and best wishes to my long-standing predecessor Andy Kano, who has moved on to another OSG group company,” concludes Art Fujiyama. “Andy’s amazing work put OSG UK in a great position for a bright future. I’m now focusing on picking up where he left off, with the aim of reaching the next level of performance and growth.”