OSG Micro Precision Drilling: Offering Solutions for Small Diameter Hole Production

When it comes to manufacturing, the devil is in the details, especially when dealing with small diameter holes. We know that in complex parts with long cycle times and high cost of manufacturing the fear of breaking small diameter drills can leave machinists resorting to slowing down processes. But fear not, OSG’s ADO-MICRO range has emerged as a machinist favourite, providing reduced cycle times and increased security that make the impossible, possible.

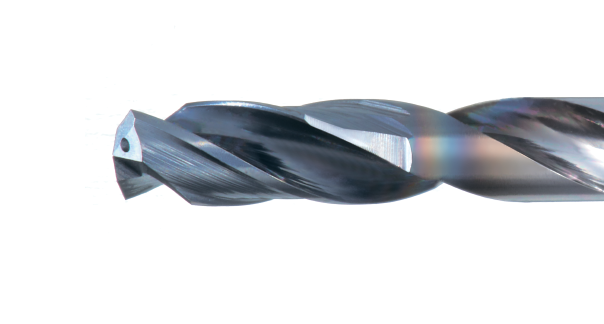

Small Diameter, Big Impact: ADO-MICRO is a small diameter carbide drill designed specifically for micro hole applications. With sizes starting at 0.70mm – 2.00mm with through coolant and drill length ratios from 2D to 30D.

Chipping Away at Problems: One of ADO-MICRO’s standout features is its double margin geometry with an extended flute and shortened end margin. This design significantly enhances chip evacuation, a notorious stumbling block in small diameter hole drilling. The double margin configuration aids the stability of the tool and reduces rifle marks on the inner surface of holes. Say goodbye to clogs and costly interruptions!

Flowing to Success: Another winning feature of the ADO-MICRO is its pair of large oil holes and a hollow shank design. This clever setup allows for a increased coolant flow, ensuring trouble-free chip evacuation and keeping the manufacturing process smooth and cost-effective.

In a world where precision matters more than ever, OSG’s Micro Drilling Solution ADO-MICRO proves that even the tiniest holes can have a massive impact on efficiency and cost-effectiveness.

Embrace the future of drilling with OSG, where challenges become opportunities.