Open Mind’s hyperMILL CAM software helps composites specialist accelerate

Melton Mowbray-based KS Composites, which operates at the pinnacle of the motorsport industry, has invested in hyperMILL CAM software from Open Mind Technologies. Operating in the motorsport market since founder Kelvin Smith opened for business in 1985, KS Composites works with numerous Formula 1, GT, Le Mans and BTCC teams.

Complementing the company’s design, FEA and CFD services is a 48,000 sq ft manufacturing site that supports with kit cutting, fitting, assembly, wet-lay composites, autoclaves, ovens, a composite shop, a machine shop and much more. Whether it’s the development of new lightweight wind turbines, the production of super-efficient alternative energy vehicles or the special demands of the aviation and military industries, KS Composites approaches all projects with the same enthusiasm and professionalism.

Dan Johnston, Business Development Manager at KS Composites, says: “We’re a turnkey composite solution provider that offers a range of services, from engineering to 3D printing and CNC machining, as well as composite manufacturing. Each customer has an individual requirement that we must respond to – everyone has nuances within their projects and programmes, and we leverage every service at our disposal to provide for our clients. Customers will initially come to us with a fully developed concept or just the genesis of an idea. What that journey looks like will depend on each client, but we fundamentally take an idea and our engineering division will provide the solution. If someone has a blueprint for a project, we’re agile and responsive enough to deliver on time.”

Justin Tallboys-Cotton, Sales Manager at Open Mind, adds: “KS Composites came to us because of their needs, which are not only metallic but also composite machining. They run everything from three-axis vertical machining centres to complex five-axis gantry machines. One thing that KS Composites liked about hyperMILL is that the licences are very modular. So while they use the five-axis licences, they don’t need all of it: KS Composites just selects the two or three modules needed to do their work. They know they can expand if needed.”

Looking at a replica race car manufactured by the company, Johnston says: “On the vehicle itself, we have carbon composite body panels and machined GRP and 3D printed elements. We’re hitting on all our core services with this vehicle. One of the first things to come into our new building was CNC machines.”

At that point, KS Composites identified the need for a CAM package that could get the most out of its CNC machines. The company went to the market and evaluated the options, saying it was clear from the outset that hyperMILL was the obvious choice.

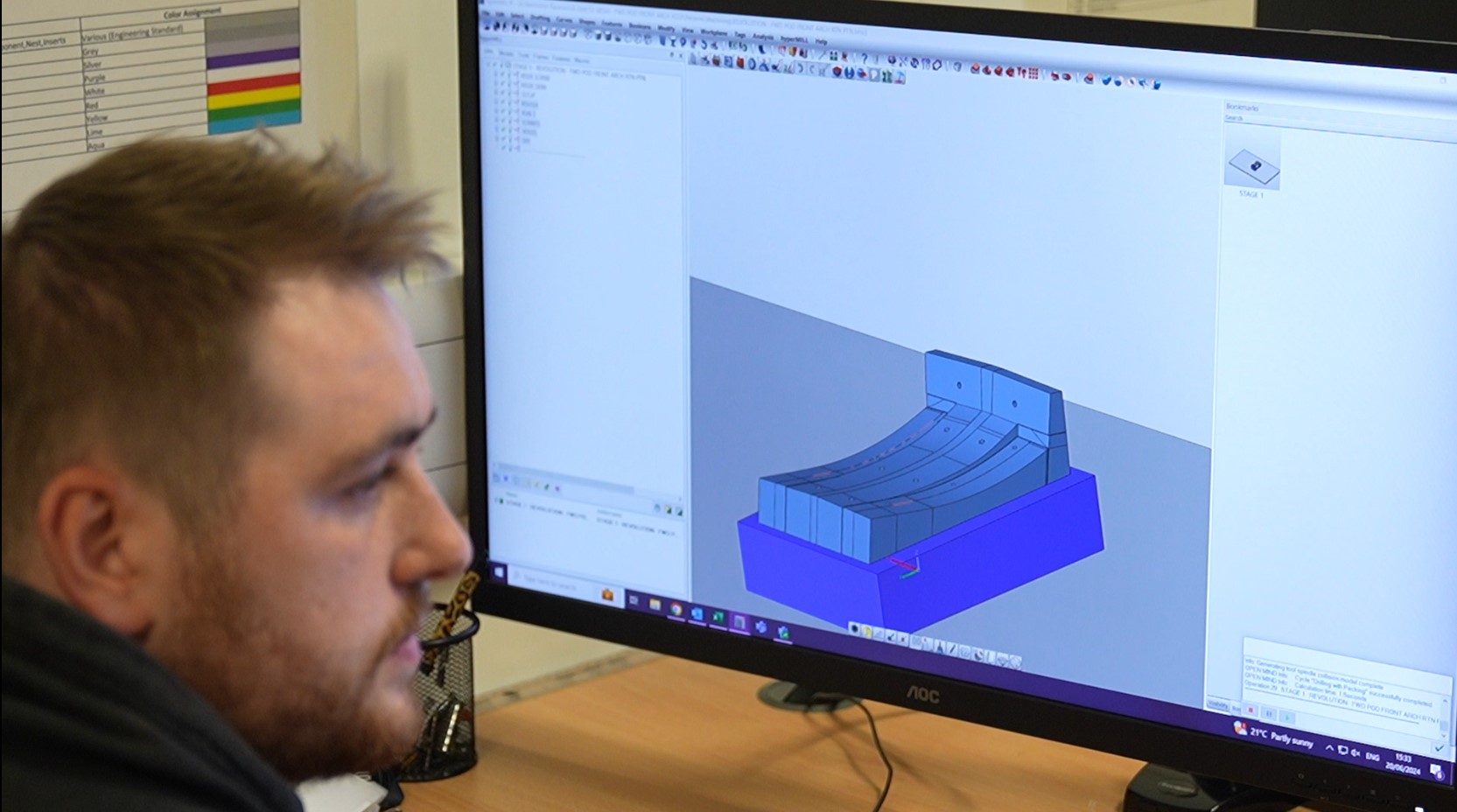

“It makes me extremely proud to see how KS Composites are embracing the tools within hyperMILL,” states Tallboys-Cotton. “For example, they colour-code their components and use bookmarks and templates. This provides consistency throughout the process, especially when programs created by different staff members work in different ways. It also helps with time to market: KS Composites can reduce their programming time to a bare minimum, ultimately getting parts on machines quicker to keep customers happy.”

Johnston concludes: “The hyperMILL CAM system is making our life so much easier, especially when we’re making things like a show vehicle. We’re representing motorsport’s pinnacle: high performance and high precision. That’s what we’ve achieved with hyperMILL.”