New workholding products to be launched for automated production

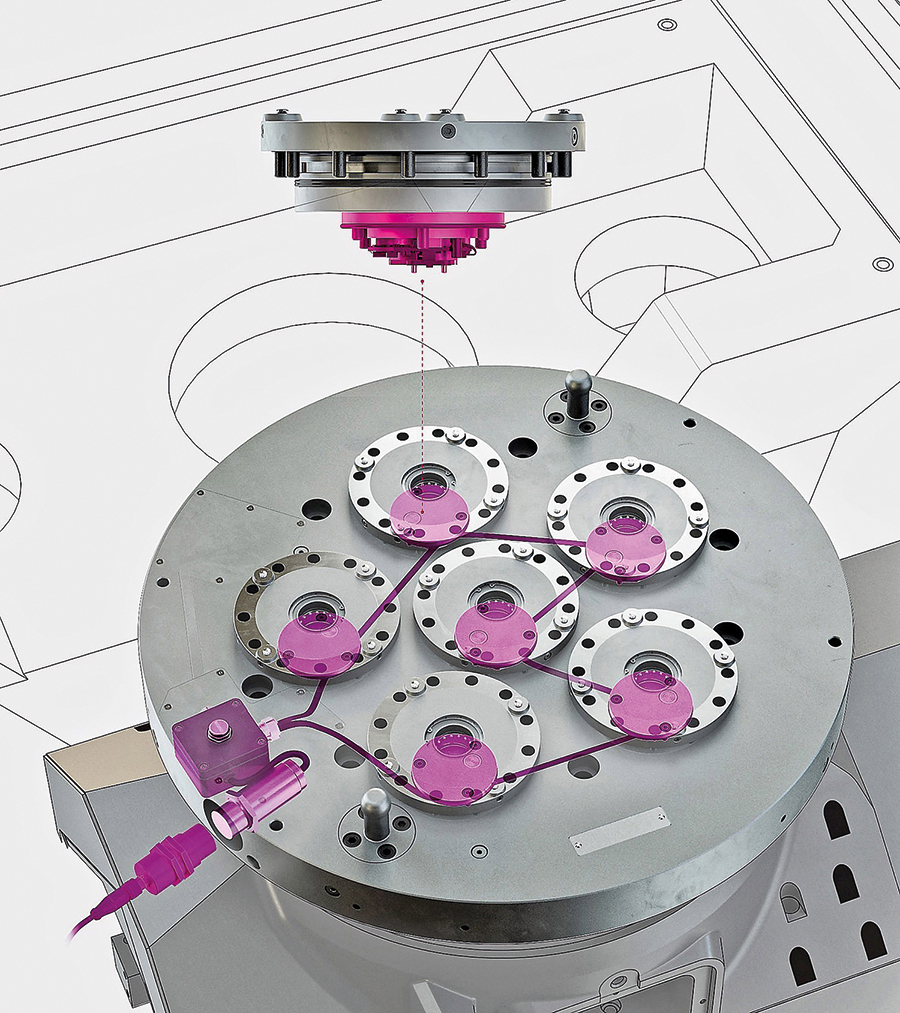

Roemheld will show for the first time in the UK a new, modular, sensor-based system that digitalises zero-point clamping by enabling digital recording of its status. STARK.intelligence enables data on workpiece loading and unloading to be integrated directly into an automated manufacturing process. Information is also provided on the condition of the clamping equipment to facilitate its scheduled maintenance.

Each fixture is equipped with its own sensor box to measure position, temperature and pressure in real-time. A master unit receives data from several units and outputs the information to different devices via an IO-Link. The device can be the machine tool’s control screen, computers in the quality assurance department or the service engineer’s smartphone.

STARK.intelligence can be combined with various STARK zero-point clamping systems and may be retrofitted easily to machine tables and quick-release fixture plates.