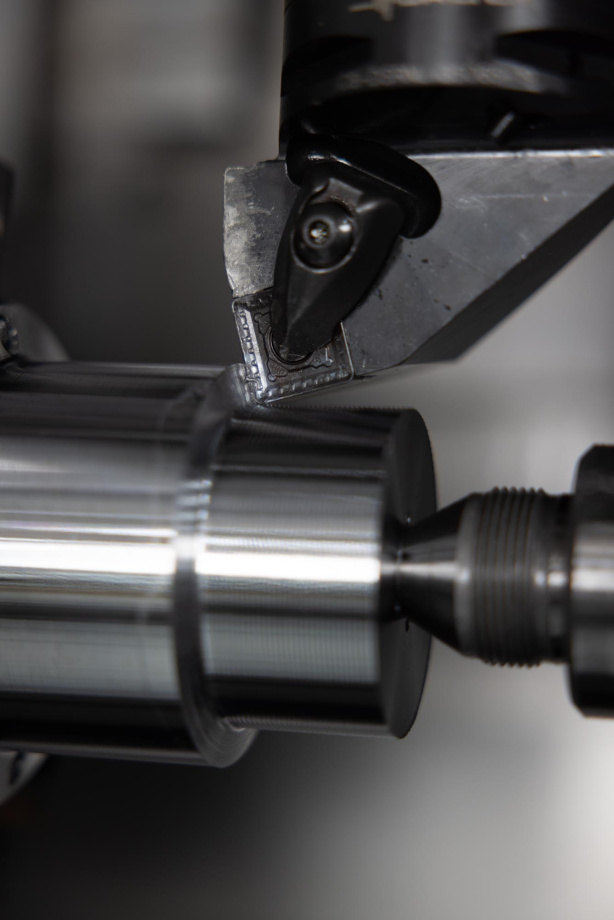

New Walter Tiger·tec® Gold rough turning inserts with HU geometries

With the new HU3, HU5 and HU7 geometries, Walter is completing its range of indexable turning inserts for heavy-duty roughing operations. The ‘H’ designation is for the negative, single-sided and therefore highly stable inserts, standing for ‘Heavy (Roughing)’, while the ‘U’ refers to their universal use. Each of the three new geometries has specific features making them suitable for different applications.

The HU7 geometry for steel and cast iron workpieces is the most stable turning indexable insert in Walter’s product range. It has a straight cutting edge and the negative protective edge chamfer ensures that it can be used at the highest feed rates with very large depths of cut of up to 17mm. It demonstrates excellent stability and is perfect for large-volume machining, even in difficult conditions. This includes the machining of forged parts or interrupted cutting.

Compared to the HU7, the HU5 geometry incorporates a curved cutting edge and an open chip breaker groove design that provides a slightly softer cutting action. The cutting pressure and cutting forces are considerably reduced. Therefore, the HU5 is the first choice insert wherever heat generation and/or vibration occur. This makes the grade particularly suitable for rough-turning high-temperature alloys and stainless steel.

The third insert design, the HU3 geometry with a V-shaped chip formation optimises chip breaking even with small depths of cut and fluctuating material removal rates. This makes the HU3 well suited for machining parts with a forged skin or varying surfaces. The HU3 has been designed primarily for use on steel materials with depths of cut from as low as 0.8mm whilst still maintaining chip control.

All three turning insert geometries are coated with the new Tiger·tec® Gold grades, WPP10G, WPP20G and the WPP30G. These impressive coating technologies further increase wear resistance due to the highly textured, multi-layered MT-TiCN structure. Not specific to, but manufacturers in the oil and gas and aerospace industries as well as manufacturers of turbines and generators in the power generation sectors, can therefore benefit from very high levels of productivity as well as process reliability.