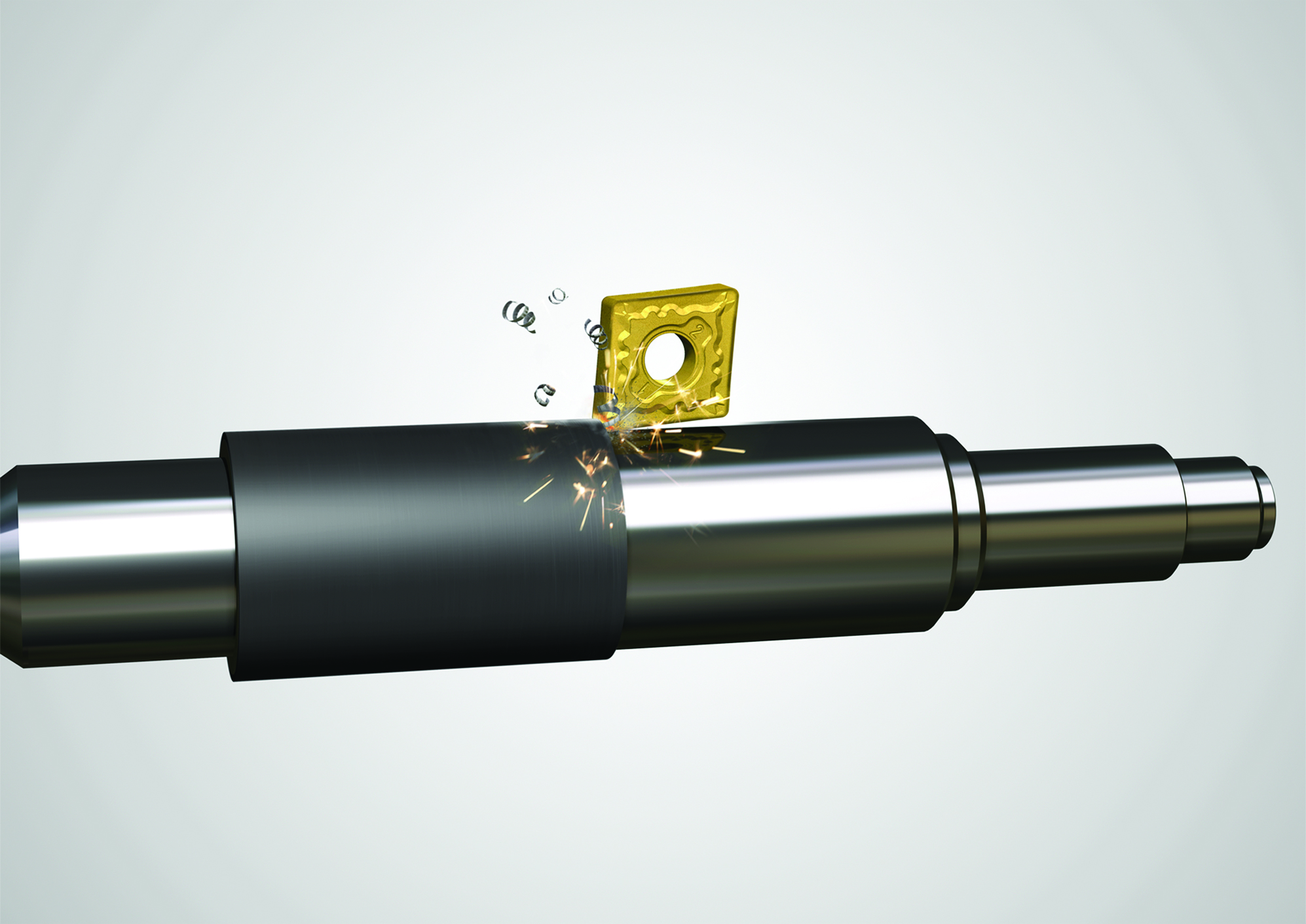

New positive inserts for MC6100 from Mitsubishi Materials

Tooling engineers and CNC machine programmers face a huge choice of turning insert grades and chipbreakers in the modern market place. Mitsubishi Materials has designed and developed two top class grades, MC6115 and MC6125. These 2 two grades have now been expanded to included positive 5°, 7° and 11° inserts.

MC6115, is a CVD coated turning grade for steel machining, which is capable of both high speed machining and providing excellent cutting edge stability.

MC6125 is highly versatile and can perform at the highest level across an increased range of different applications. This enables an easy first choice start point when choosing an insert for turning steels and thereby reduces the inventory levels of inserts.

Both grades have innovative CVD coatings that provide the double benefit of excellent cutting edge stability and long tool life for machining a wide range of steels.

MC6115 has the combination of a high hardness base material and new thick Al2O3 outer coating with improved wear and peeling resistance at high temperatures while the MC6125 has the combination of a tough base material and as well as the advatages of the multi-layered of Al2O3 coating for improved wear resistance at high temperatures. It also has higher peeling resistance and cutting edge stability achieved by super TOUGH-GRIP technology. This provides the ultimate enhancement of the adhesion between the Al2O3 and TiCN base coating layers.

Super Nano Texture Technology

The outstanding crystal orientation of the Al2O3 coating has been developed by improving the conventional Nano Texture Technology. These technological improvements increase both wear resistance and tool life.

A new range of geometries

The combination of the tough substrate and wear resistant coatings is also extremely useful for the new positive geometry range of 5°, 7° and 11°. The introduction of the positive inserts enables an even wider range of steel turning applications including boring and steeper profiling work.

The inserts are finished in a gold colour for easy identification of used edges and the new are available in a wide range of positive geometries and 10 different chipbreakers –

5° VBMT and WBMT.

7° CCMT, DCMT, RCMT, RCMX, SCMT, TCMT, VCMT,

WCMT and XCMT.

11° CPMH, TPMH and WPMT.

11° without hole SPMR, SPMN TPMR and TPMN.

MC6125 Multi-layer Coating Structure

Gold colour outer layer for used corner identification.

Multiple Ti compounds and an Al2O3 layer for wear resistance.

Super Nano Texture Al2O3 layer for resistance to high temperatures.

Super TOUGH-Grip for adhesion between layers.

Fine granular TiCN layer for additional wear resistance.

View the MC6100 brochure by clicking the link below.