New LK CMMs suit large-scale, heavy-duty measurement

Two new ranges of bridge-type coordinate measuring machine (CMM), MAXIMA and MAXIMA R, have been launched by LK Metrology to meet rapidly expanding demand for the precise measurement of large, heavy components, often of significant complexity. The machines are suited to quality control applications across industries such as aerospace, energy, automotive, heavy engineering, power generation, transportation and industrial machinery, where consistent measurement results and long-term stability are paramount.

LK’s ceramic materials for the beam and spindle guideways, which the company says provide a near-perfect stiffness-to-weight ratio, combine with a robust structure to deliver consistent accuracy and repeatable results in the order of 3 µm. Low gap, high-efficiency air bearings and zero-hysteresis drive systems ensure unmatched quality and low maintenance, reports the company.

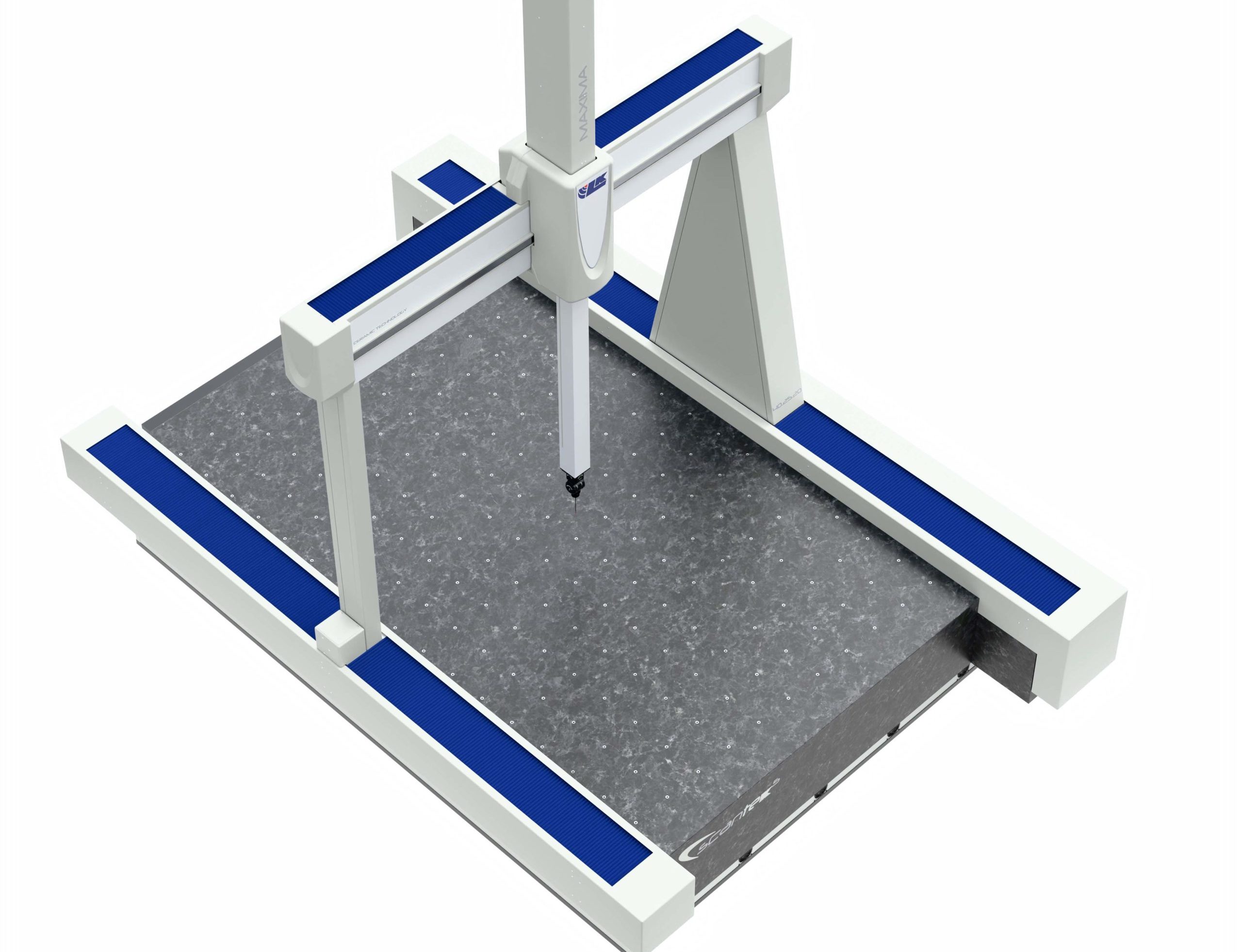

According to LK, the MAXIMA series offers the largest measurement volume available on the market, from 12 to 72 cubic metres, of any CMM with a granite table. Its high capacity provides stability, ensuring the machine maintains peak performance even when supporting heavy workpieces. Included in the range are 28 models in six table lengths from 3 to 8 m, and seven variants of bridge cross section up to 3 m.

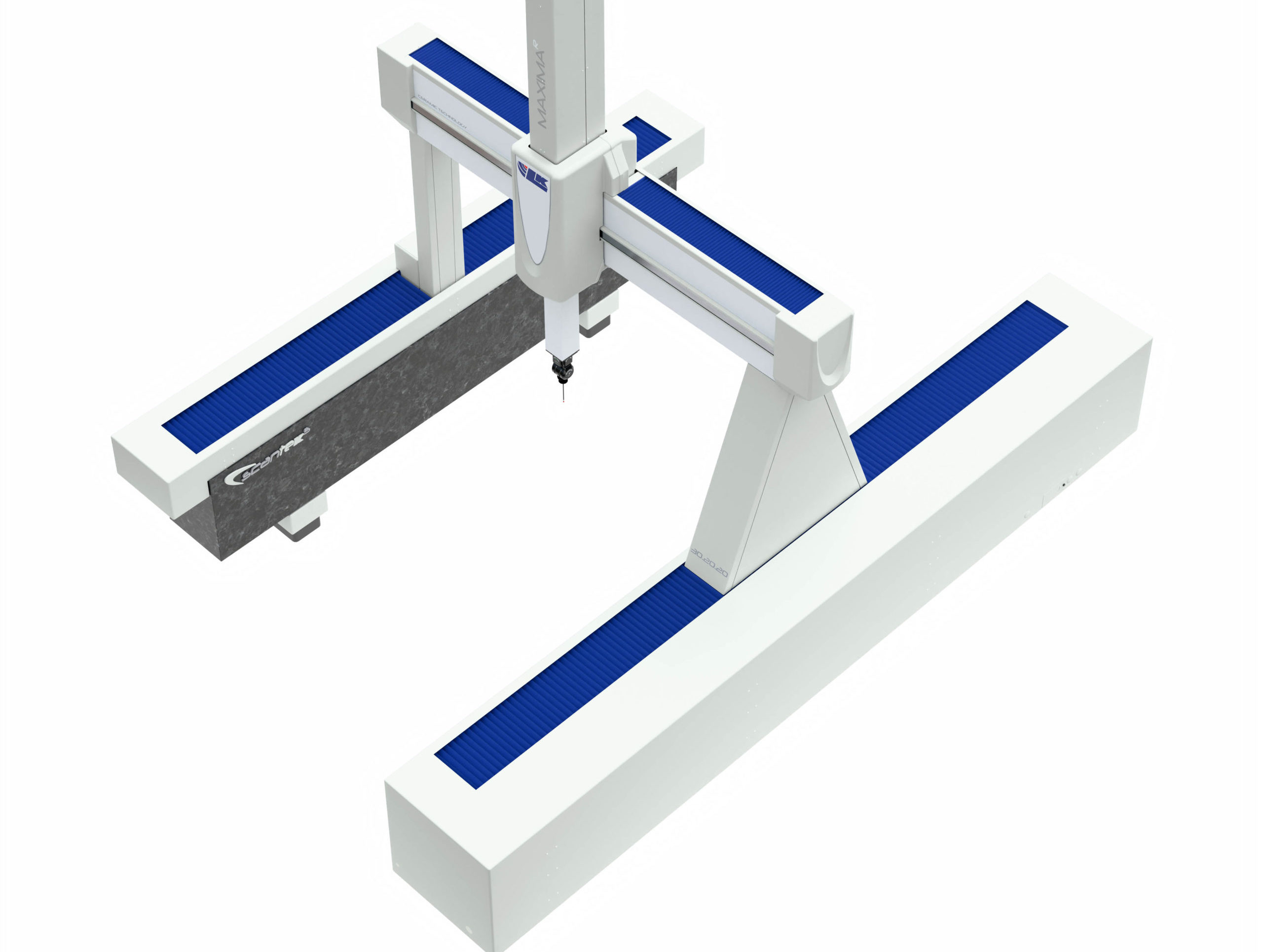

Complementing this offering, the MAXIMA R range features a twin-rail design engineered for heavyweight workpieces. Its structure enables safe and efficient loading of heavy components on the floor and seamless integration with automated transfer systems. A key advantage of these models is that the design eliminates the need for special foundations, while offering stability, simplified installation and cost efficiency. The MAXIMA R is available in the same range of sizes as the table-type models.

Both new CMM product lines are equipped with an LK controller and come in several configurations: probe-ready for tactile inspection and laser scanning using a PH10MQ Plus multi-sensor indexing probe head with auto-joint; in ScanTek configuration with a multi-sensor REVO2 head to provide 5-axis scanning; or with an SP80 ultra-accurate fixed scanning head with probe builds up to 1 m. The PH10MQ-ready models feature a multi-wire cable that supports both SLK and L/LC/XC laser scanner technologies, eliminating the need for a separate probe-ready configuration for each type.

The introduction of the MAXIMA and MAXIMA R ranges reinforces LK Metrology’s commitment to providing market-leading, multi-sensor solutions for the most challenging metrology applications globally. The machines fulfil a critical need by combining high-precision build at the firm’s Castle Donington factory in Derbyshire, UK with very substantial measuring envelopes, providing a reliable and accurate solution for large-scale inspection requirements in manufacturing.