New end mill line is a star performer

TaeguTec has expanded its StarMill SED 7 range of solid-carbide end mills with the introduction of two variants designed to enhance machining performance. The 4xD long type and chip-splitter type provide efficiency when machining difficult-to-cut materials such as titanium alloys and stainless steel, offering increased productivity, improved surface finishes and longer tool life.

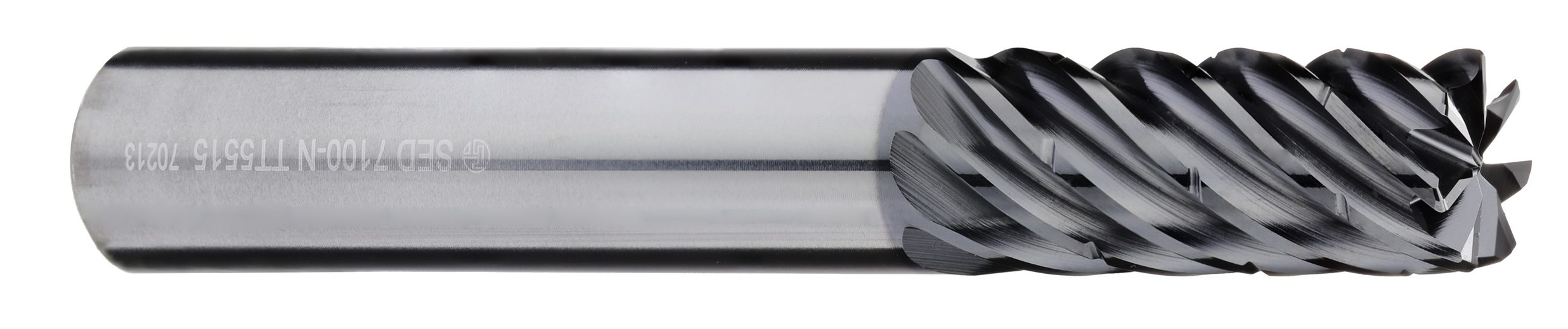

The TaeguTec StarMill SED 7 solid-carbide end mills have already established a strong reputation in the industry due to their seven-flute design, unequal spacing of cutting edges, and optimised helix angle. This combination delivers high surface quality and material removal rates. The introduction of the 4xD long type and chip-splitter type further broadens the operational capabilities of the SED 7 line, allowing manufacturers to tackle more complex machining requirements with greater ease.

The 4xD long type end mill handles greater depths of cut, making it suitable for operations requiring extended axial engagement. Its enhanced design ensures stability and precision even in demanding applications, reports TaeguTec, delivering consistent results across a wide range of machining tasks. The StarMill 4xD long series is available in diameters ranging from 6 to 20mm, featuring a 0.5mm corner radius to maintain durability during heavy-duty machining. With flute lengths ranging from 15 to 80mm and an overall length of 57 to 150mm, the robust end mills can reach deep cavities while retaining optimal machining parameters.

Similarly, the StarMill chip-splitter type end mills are available with diameters from 6 to 20mm and a flute length from 15 to 80mm. Optimised for rough machining and high-feed applications, the StarMill chip splitter features an overall length ranging from 57 to 150mm, with a particularly thick core that ensures low cutting forces and good chip evacuation. This combination reduces heat build up and minimises tool wear with swarf removal enhanced by a 38-degree high-helix flute angle. By minimising chip volume and effectively controlling chip formation, the chip splitter series ensures smoother operation and longer tool life.

One of the most distinctive features of the two new additions to the StarMill SED 7 line is the seven-flute design with unequal cutting edge spacing, which reduces vibration and noise. The optimised helix angle, calibrated explicitly for titanium alloys and stainless steel, further boosts the line’s performance, enabling higher feed rates with minimal deflection. The result is an increase in productivity while maintaining precision and quality.

Field tests and case studies have demonstrated the superiority of the expanded SED 7 line over its competitors. In a recent TaeguTec study conducted on titanium alloy (Ti-6Al-4V), the TT5515 grade SED 7120-4D-N delivered an 82% increase in productivity by enabling higher material removal rates while extending tool life by 50%. The field test also highlighted reduced noise levels and significantly better surface finishes when compared with rival product lines, reports the company.

The use of TT5515 grade further ensures wear resistance and effective heat management, contributing to extended tool longevity and reliable performance under demanding conditions.

The expanded StarMill SED 7 line is suitable for applications across multiple industries. Aerospace and automotive manufacturers can leverage their capabilities to machine titanium and stainless-steel components with reduced cycle times. Medical device manufacturers, on the other hand, will benefit from the high-accuracy performance delivered by the new variants, especially when working with difficult-to-machine alloys. General engineering applications also benefit from the versatility and precision, making it a preferred choice for slotting, trochoidal machining and high-feed milling operations.