New drills for demanding machining applications

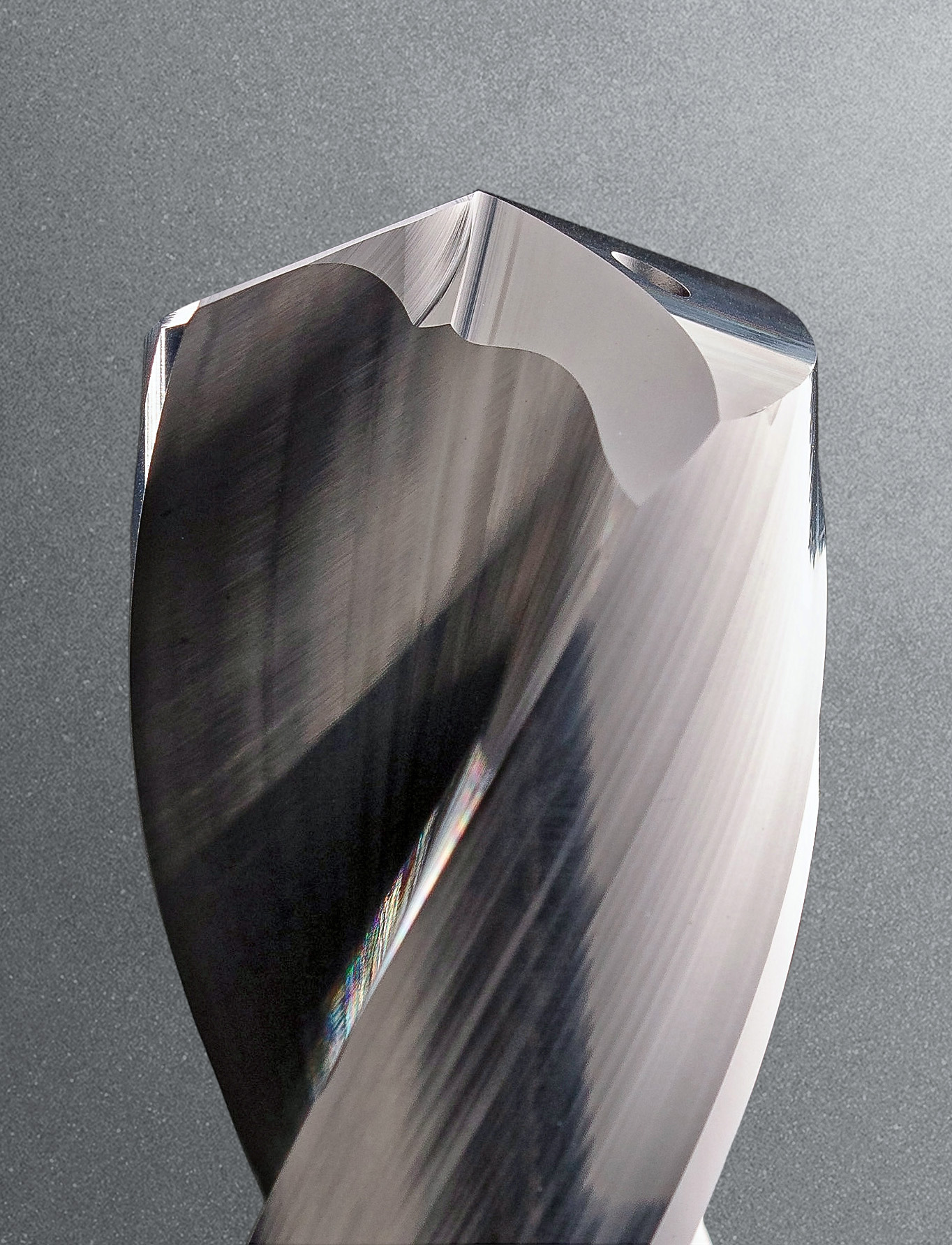

Tooling manufacturer Horn has introduced a new, solid carbide drilling system, D1122, for highly productive machining of steels and cast materials. The straight, stable cutting edge reduces the formation of built-up edges, while corner chamfers contribute to wear protection, resulting in long tool life. A specially developed HiPIMS (high-power impulse magnetron sputtering) coating delivers excellent wear resistance.

Horn says that the carbide tools have an attractive price-to-performance ratio. The customised cutting edge geometry demonstrates an elevated level of process reliability and open, precision-ground flutes ensure reliable chip evacuation. The drills are offered with point angles of 135 degrees and 140 degrees. Two land margins result in stability and reduced friction.

The 135-degree type is available in an 8 x diameter version with four land margins for optimum drilling quality and high positioning accuracy. The 140-degree drill is available in short and long versions (3 x D and 5 x D) in accordance with DIN 6537. The optimised point enables efficient chip formation and coolant distribution for both angles. All drill types are equipped with an internal coolant supply.