New Dörries VT 28 VTL supports one-hit machining of large parts

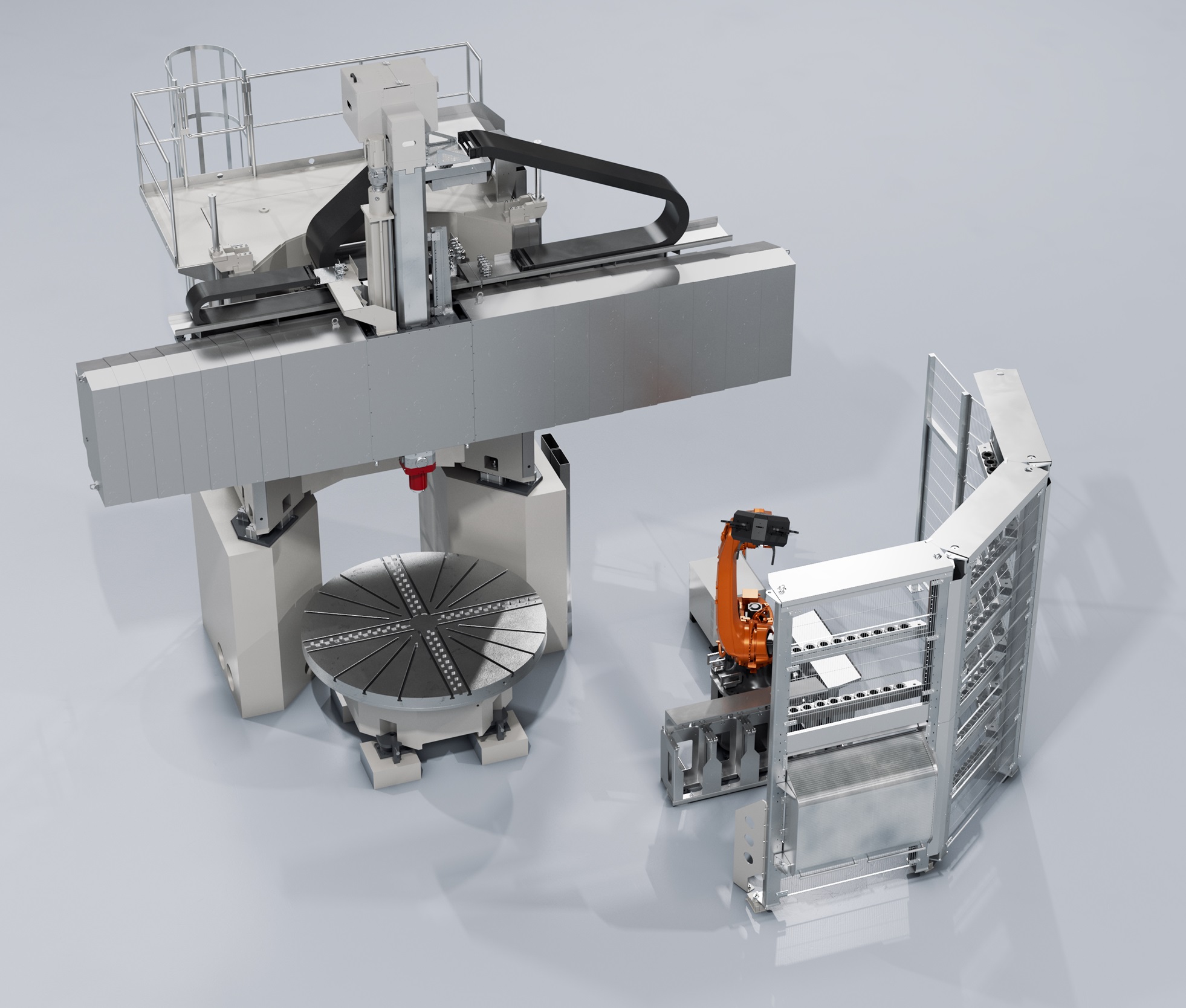

The new Dörries VT 28 vertical turning lathe (VTL) from Starrag will aid the one-hit machining of large components in the aerospace, power generation and offshore sectors. Combining proven technology from the Dörries CONTUMAT VCE series, the Dörries VT 28 introduces a raft of solutions and technologies that the company says enhance both machining performance and productivity.

Capable of machining heavy components up to 17 tonnes with a maximum diameter of 2.8 m and a height of 2.65 m, the Dörries VT 28 has been developed as a multifunctional, high-precision and flexible vertical turning centre for everything from rough to finish machining in a single operation. The compact single-column VTL is suitable for machining tasks that include turning, drilling, boring, milling and grinding.

Constructed with a single-column design for static and dynamic rigidity – as well as compact on-floor installation – the Dörries VT 28 column base is cast above ground to minimise foundation costs. The column base forms part of the machine foundations. Further enhancing the stability and rigidity characteristics of the Dörries VT 28 are wear-free hydrostatic guides in all linear axes that maximise the vibration-damping performance. The new hydrostatic system reacts with minimum fluctuation to temperature deviations and changes in viscosity.

From a dimensional perspective, the Dörries VT 28 offers a 2.8 m swing diameter and a 2.5 m table diameter. The machine provides torque of 11 kNm with 98 kW on the main S1 drive and a speed range of 250 rpm. This capability enables users to achieve high depths of cut at high machining parameters.

From a flexibility standpoint, the Dörries VT 28 has a ‘master head’ concept that enables the decoupling of the milling drive and tool interface to provide additional protection against collisions. The machine’s flexibility also allows users to integrate gear-driven spindles, motorised spindles and fork-type heads.

The ergonomic design of the Dörries VT 28 with central layout offers easy access for the users and service personnel. It also supports automation with flexible robotic tool handling that is available to expand the machine’s potential. Tool life and performance are maximised via a 350 bar high-pressure coolant system.