New Collet System to Improve Security

High-precision collets with a new anti-pullout system that guarantees the security and performance of your cutting tools is the latest technology advancement available from Tamworth cutting tool manufacturer Industrial Tooling Corporation (ITC). As the UK’s leading manufacturer and supplier of high-quality cutting tools and ancillaries, ITC has now introduced the new PG (perfect grip) Straight Collet system from BIG KAISER.

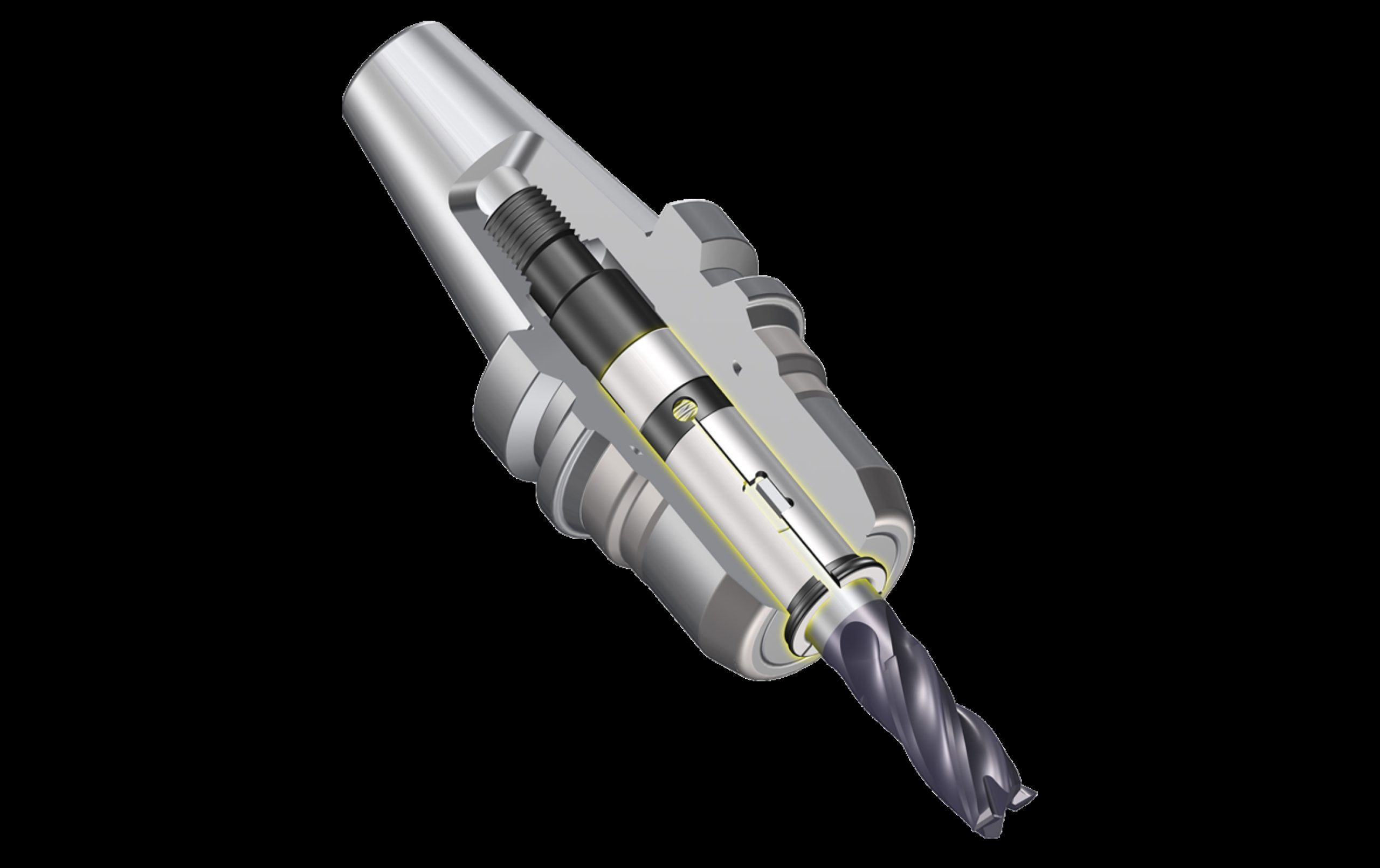

The PG (Perfect Grip) Straight Collet system developed by BIG KAISER includes a new anti-pullout system that locks the collet and cutter to the toolholder body. This innovative design eliminates cutter slippage and also the potential for cutter pull out during demanding metal removal applications. The new system is particularly suited to high dynamic milling and high-speed milling in difficult materials.

BIG KAISER has launched three sizes of collet with the new anti-pullout system and these will be available in the UK imminently after their world premiere at the recent EMO exhibition in Hannover. are now available. While larger sizes have been previously available, this is the first time that customers can mill in difficult materials such as Inconel and titanium down to just 10mm in diameter. The three size variations include a 10, 12 and 16mm PG Straight Collet system.

Unlike other systems, the PG does not require the purchase of specially modified and inherently expensive end mills. Instead, it uses existing standard carbide or HSS end mill designations. Standard notches found on typical Weldon-type end mills will readily accept the locking key insert on the new PG system. This enables fast and easy assembly. At EMO 2023, BIG KAISER showcased the full range of high-precision systems alongside the new PG Straight Collet system.

Commenting upon this exciting new technology, Giampaolo Roccatello, Chief Sales & Marketing Officer for Europe at BIG KAISER says: “By improving cutting tool security, the PG collet gives manufacturers greater confidence when machining expensive materials and very large or complex parts that are technically challenging to machine. This is especially the case within the aerospace industry where part costs can be extremely high. When machining at the end of a prolonged process where a lot of machining time has already been invested, a failure or tool slippage can ruin the whole part. The financial implications of such a failure can be devastating.”

The impressive new PG collet system is for use with BIG KAISER’s MEGA Double Power Chuck and Hi-Power Milling Chuck which are available from ITC. To improve compatibility and reduce costs, one holder accommodates four sizes. This is credited to the reduction sleeve applied within the collet. Even if a tool is damaged and cannot be removed from the collet, the collet itself can be disassembled from the tool holder.