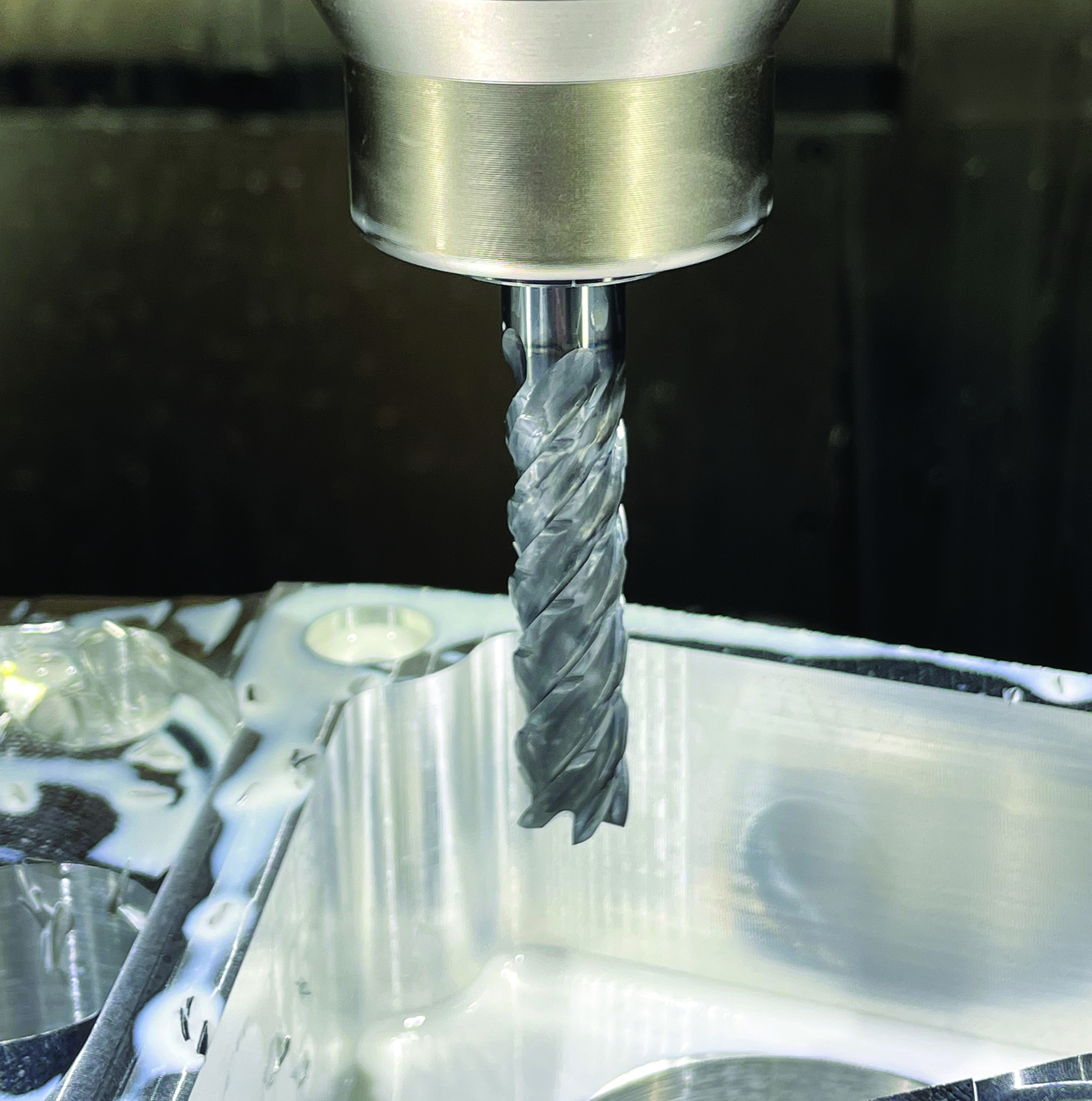

Mitsubishi Materials expands series of chipbreaker end-mills

Mitsubishi Materials has recently expanded the VQCS chipbreaker series of carbide end mills to include an exceptional, new extra-long type in square and corner radius styles. The extra-long version, introduced together with long and semi-long flute length types are supplied in square and corner radii geometry. The existing series of the square corner long type is boosted with the addition of larger Ø16 mm and Ø20 mm sizes.

These latest additions provide a more versatile choice for end users. The extra-long types have an impressive cutting edge length of 30mm for the Ø6 end mills, 40 mm for the Ø8 type through to an exceptionally long 50 mm cutting length for the Ø10 mm type.

The whole VQ chip breaker series, designed for specialised roughing applications on heat resistant super alloys. They can also perform effectively on hardened stainless steels and can even machine materials such as copper and copper alloys as well as carbon and alloy steels.

The major features of the new end mills are the special flutes that have notches to provide an effective chip breaking function. The 5 flutes used on each diameter also displays a rigid cross-sectional geometry to provide excellent chip evacuation, this makes the VQCS end mills ideal for trochoidal machining. Furthermore, the irregular pitch of the flutes and micro clearance angle of the peripheral cutting edge provides excellent vibration damping properties for stability and reliability. The extensive range of distinctive features is concluded with a unique end cutting edge geometry that achieves high chipping resistance.

The latest coating and ZERO-μ Surface

Much of the reliability and high performance of the VQ series can be attributed to the newly developed (Al,Cr)N group-based coating which delivers substantially improved wear resistance over conventional coatings. The extreme heat and oxidation resistance and lower coefficient of friction of the new coating means this next generation of end mills can maximise performance and help prevent tool wear even under the harshest of cutting conditions such as when machining stainless steels and difficult-to-cut materials.

Availability

The new types join the existing VQCS family and are available in semi-long, long and extra-long effective cut lengths:

NEW – Semi-long, corner radius

VQJCSRB – Ø6 – Ø20 radii 0.1 mm – 6 mm

NEW – Long, corner radius

VQLCSRB – Ø6 – Ø20 radii 0.1 mm – 6 mm

Long square corner

VQLCS – Ø16 & Ø20

NEW – Extra – long, corner radius

VQELCSRB – Ø6 – Ø20 radii 0.1 mm – 6 mm

NEW – Extra-long square corner

VQELCS – Ø6 – Ø20