Mitsubishi Materials expands range of MV-grade milling inserts

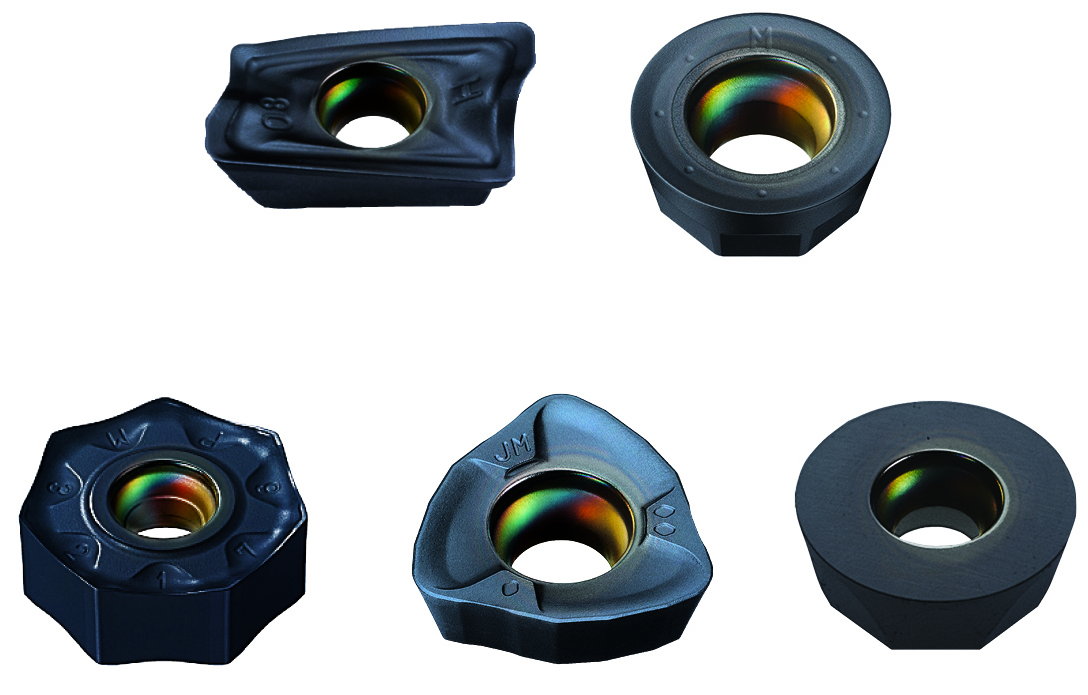

Driven by the performance and success of the first tranche of MV grade inserts that were released for seven milling cutters, Mitsubishi Materials has expanded the range with 62 new inserts for a further five milling tools.

Feedback from the market suggested that the MV1020 and MV1030 grades should be available for a wider range of milling inserts and for more cutter types. The latest inserts are for use on the larger AHX640 cutter, the APX series and in the company’s round type ARP and BRP cutter bodies. Last but not least, the high-feed AJX-type cutter can now feature MV grades.

The MV1000 series includes two grades for milling – MV1020 and MV1030 – for machining a wide range of materials from alloy and stainless steels through to cast iron.

MV1020 has advanced wear and thermal shock resistance, while also achieving stable cutting at high cutting speeds, especially when machining steel and ductile cast iron.

MV1030 has the new Al-rich coating, which also provides high wear resistance. With an ability to prevent sudden breakage, reliability was also realised, especially during problematic wet cutting where thermal shock is prevalent. This same benefit of reliability is also present when machining stainless steels.

The Al-rich coating is in fact a CVD coating of aluminium titanium nitride (Al,Ti)N, a compound of aluminium and titanium that sees widespread use as a coating for advanced cutting tools because of its hard and heat-resistant properties. The hardness of (Al,Ti)N increases in proportion with the Al content ratio. However, with conventional technology, when the Al content ratio exceeds 60%, the crystal structure changes and the hardness of the (Al,Ti)N decreases.

Using a new coating process based on Mitsubishi Materials’ proprietary technology, the Al-rich coating does not change its crystal structure even when increasing the Al content. The process enables higher Al content and, in turn, (Al,Ti)N with higher hardness.