Metal additive manufacturing specialist achieves several milestones

Meltio, which designs and produces metal additive manufacturing solutions for industry, has achieved several significant milestones, further strengthening its business and reinforcing the global impact of its patented metal 3D printing technology.

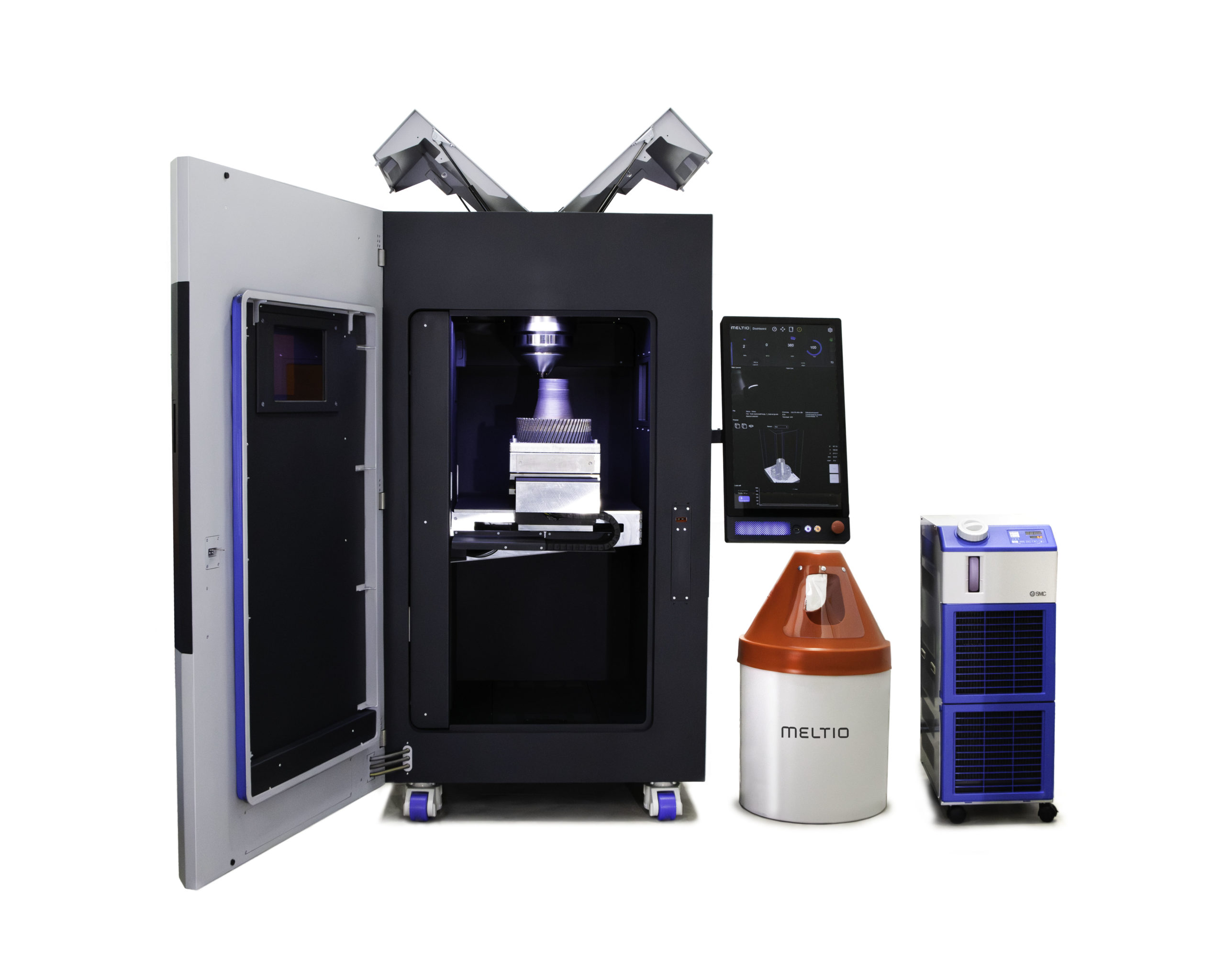

Closing 2024 on a high note, Meltio received the 2024 3DPI Award for its most advanced 3D printer, the Meltio M600. It is the first time a Spanish additive manufacturing company has received this award. Securing the 2024 3DPI Award follows on from becoming National SME of the Year 2023, granted by the Spanish Chamber of Commerce and Banco Santander, and presented by His Majesty King Felipe VI in recognition of Meltio’s innovation and contributions to the industrial sector.

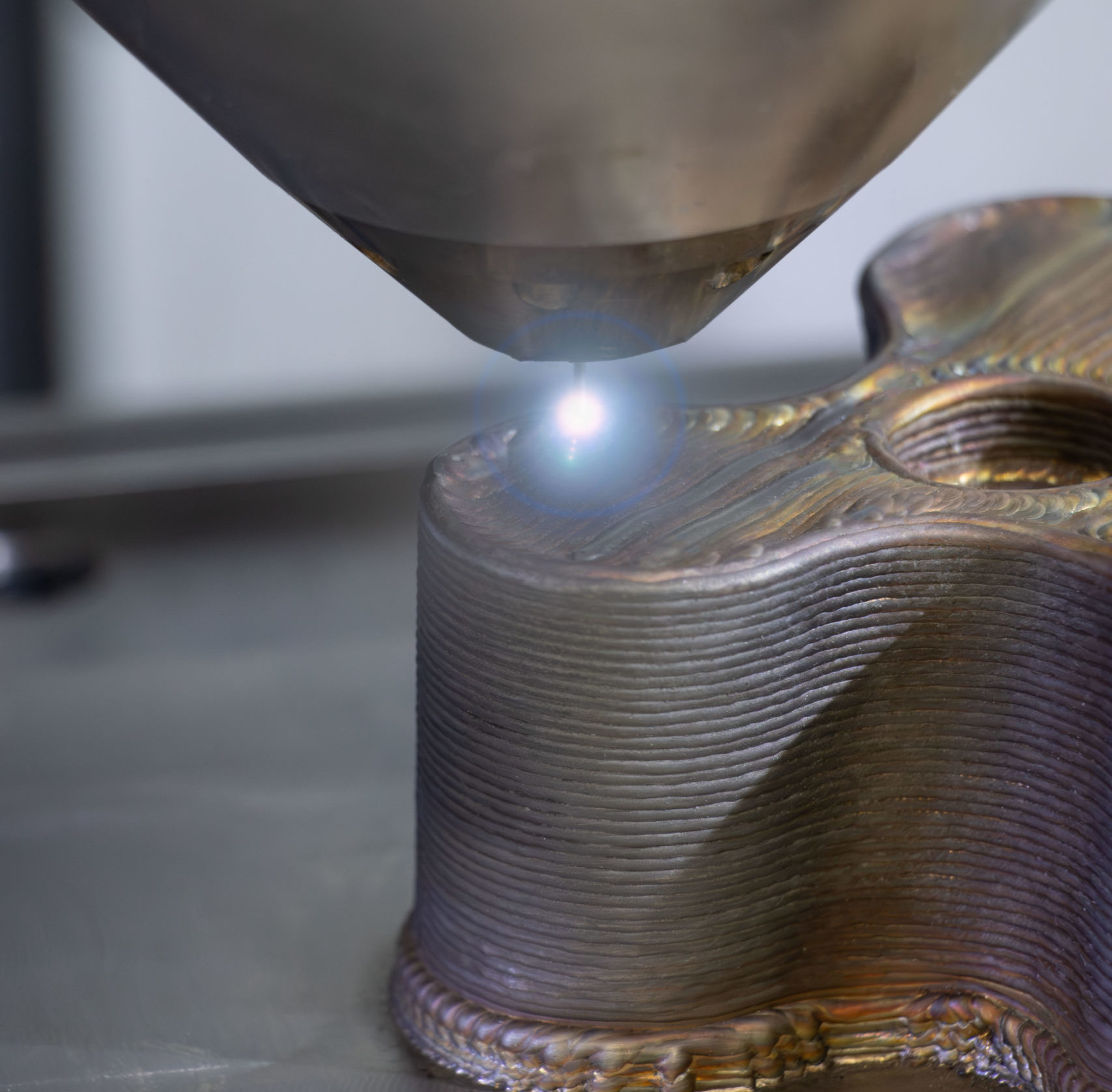

2024 was a pivotal year for Meltio, marked by the launch of two new solutions: the aforementioned Meltio M600 printer, and Meltio Engine Blue, an industrial system enabling the integration of Meltio’s 3D printing laser head into robotic arms and CNC machines. These innovations expand the ability to manufacture complex and large metal parts.

As an assessment of the year 2024, company CEO Angel Llavero Lopez de Villalta says: “The past year has confirmed the trend in the incorporation of additive manufacturing technology as a mass production technology in industries around the world. Meltio is becoming global thanks to our technology as a reliable alternative or complement to traditional manufacturing technologies.

In further news, the company increased its turnover by more than 50% in 2024 compared with the previous year.

Ildefonso Fuentes, Meltio’s CFO, says: “Last year, we continued to maintain our clearly upward trend in terms of results. I would like to emphasise that our year-over-year growth is fundamentally based on clear organic growth. Our strategic decision to work on organic growth in the current context of global market uncertainty is particularly key to the long-term success of Meltio’s business”.

In light of the current international geopolitical landscape, Fuentes reaffirms Meltio’s commitment to innovation as a driving force for growth and resilience: “Innovation remains the key driver at Meltio. New materials and technologies are being developed that enable more advanced applications that together with improved production efficiency will allow for greater adoption in various industries.”

Meltio is a partner for global industries that require advanced repair and manufacturing solutions for metal parts in materials such as aluminum, copper, stainless steels, titanium, Inconel and nickel, among others. The company has validation from organisations such as the US Navy, the French Navy (Marine Nationale), and the Spanish air, land and naval forces.

Lukas Hoppe, head of R&D at Meltio, says: “Looking back at 2024, from a technological point of view it has been the most important year in our history since the launch of the first products back in 2019. With the launch of the new Meltio M600 and Meltio Engine Blue metal 3D printer with the new blue laser system, we’re now able to meet the needs of industrial users with fast, reliable and easy-to-use solutions.

“Looking ahead to 2025, we foresee developments that could surpass the significance of our 2024 breakthroughs. Our goal is to realise the full potential of laser wire deposition through cutting-edge software solutions, which will redefine the way our technology is used. On the hardware side, we’re focused on adding new capabilities and delivering even greater performance for the M600 and Meltio Engine Blue, ensuring that these platforms remain at the forefront of innovation in industrial manufacturing.”

Looking ahead to the remainder of 2025, Meltio plans to expand the capabilities of these platforms, focusing on the development of advanced software solutions that maximize the potential of its technology that is backed by more than 500 systems installed worldwide since 2019. Based on a cleaner, safer, more economical, faster process, with higher quality in the final finish and sustainable, Meltio’s technology reduces costs in industrial production and offers optimal results in terms of print definition and density of 3D printed parts.