Mazak aims to empower at EMO with next level of innovation and integration

Yamazaki Mazak is aiming to empower machine users at EMO 2025 by showcasing a range of new machine and automation technologies, including seven world and five European debuts.

Exhibiting under the theme ‘Experience innovation, empower your future’, the Mazak stand will highlight the benefits of a real partnership between machine manufacturer and user, with a stand that places customer success, smart automation and digital integration at the heart of modern manufacturing. Visitors will experience a comprehensive showcase of new machine tools, connected technologies and expert support services – all designed to empower customers.

The Mazak stand will host a total of 20 machines – five manufactured in Europe – that highlight the breadth of the technologies available. These extend from three-axis lathes and vertical machining centres offering an affordable introduction to the Mazak brand, to the most sophisticated Integrex level of multi-tasking and Auto Gear technology.

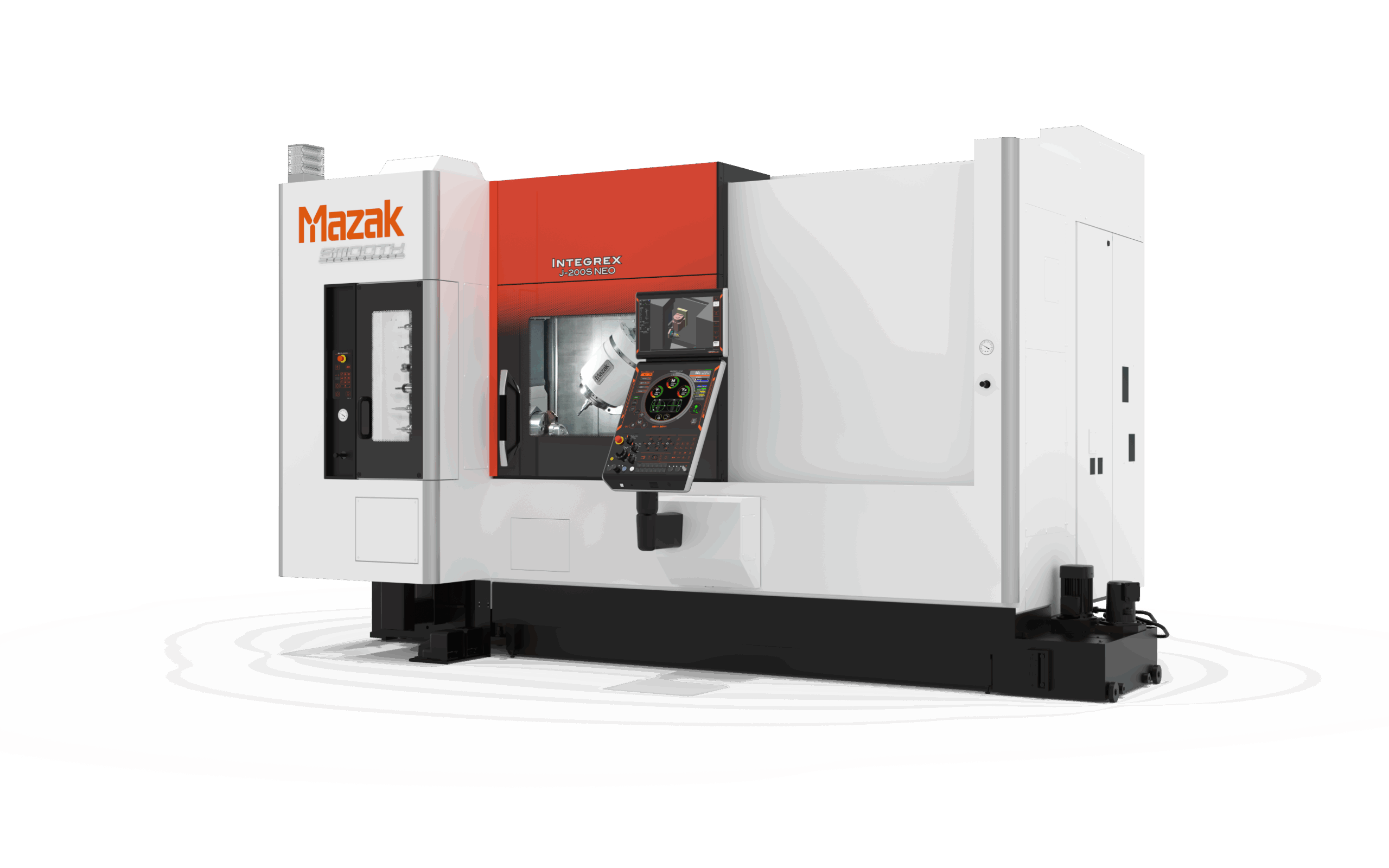

The new machines on show will include the Integrex j-200 NEO, shown for the first time in Europe, which combines productivity in complex high-mix/low-volume batch work with an attractive price.

A central concept for Mazak at EMO 2025 will be the depth of process integration that customers can benefit from when partnering with the machine tool builder. In practice, this will be displayed via a live process optimisation demonstration, which will use both a machine tool and laser processing machine to increase productivity, while reducing both carbon footprint and cost-per-part.

This EMO, the Mazak stand will also feature a ‘Solutions Centre’ providing a deep dive into Mazak technology and the services available beyond the machine. With advice and expertise available on advanced machining, hybrid technology, automation solutions, digitalisation and integrated smart manufacturing solutions, visitors can expect to come away with some key insights on how to boost productivity and efficiency in their manufacturing operations.

With over 40 years of development, Mazak says Mazatrol will be showcased as a key solution that continues to deliver cutting-edge machine performance with conversational programming for new users. Visitors can watch live demonstrations and try out Quick Mazatrol, digital set-up tools, and intelligent programming features that simplify operations and reduce setup times. It’s a hands-on space for customers to understand how Mazak control systems make a practical impact on everyday productivity. A major highlight will be a demonstration of the latest digital manufacturing software Mazatrol DX, which can transform cycle times and productivity for machine users.

Visitors will also receive plenty of information on advanced machining applications, such as additive machining, friction stir welding, advanced five-axis work and gear cutting, which extend Mazak’s ‘Done-In-One’ concept into new technologies and applications. This can result in fewer outsourced processes, shortened lead times and reduced costs for machine users.

In addition, Mazak will present 12 different automation solutions that support flexible, high-mix, low-volume production. From multi-pallet and robotic part loading to smart tool handling and integrated cells, the stand will demonstrate how automation can be seamlessly integrated to increase output, reduce labour pressures and enhance profitability.

Mazak’s approach to automation is clear: integration should be simple, scalable and fully supported. Every automation solution is engineered to work in harmony with Mazak machines, making adoption easier and results faster to achieve.

Richard Smith, European Group Managing Director at Yamazaki Mazak, says: “Everything on the Mazak stand is guided by a simple philosophy: helping customers build more productive, resilient and competitive operations. As a family-owned company with a proud Japanese heritage, Mazak has always placed long-term relationships at the centre of its approach. The company’s reputation is built not only on innovation, but on decades of trusted partnerships with manufacturers around the world. Whether through advanced automation, intuitive CNC control, smart service programmes or digital integration, Mazak is committed to serving as a reliable, forward-thinking partner for its customers – today, tomorrow and for the future of manufacturing.”