MAPAL tool management engineered in record time for major engine plant

MAPAL’s offer for the series production of the motor block required for a new DEUTZ 3.9-litre diesel engine included almost 100 different tools, as well as tool holders and adapters. Effective tool management was therefore a priority. However, in the capable hands of MAPAL, the Zafra, Spain facility of DEUTZ knew it could rely on the delivery of an optimised solution.

Engines were already being built in 1875 at the site in Zafra where DEUTZ today has its main factory for processing engine components. Engine blocks, cylinder blocks, connecting rods and gears are produced here by around 500 employees in modern manufacturing facilities for the group’s assembly lines in Cologne and Ulm, as well as for other customers.

DEUTZ’s new 3.9-litre diesel engine sees most use in agricultural and construction machines. As an industrial engine, it offers long service life and will remain in production until at least 2035. Series production is to start in the coming year after the current prototype phase. Some 50,000 units per annum will require manufacturing. This engine, which will be available in a power range from 55 to 160 kW, represents an important future project for Deutz. As it’s the same size as its 3.6-litre predecessor, it is suitable for installation in the same vehicles, where it will provide efficient performance.

“Our engines are typically deployed in off-highway applications like agricultural and construction machines, which are in constant use and move heavy loads,” explains Alejandro Castilla De La Hoya, Zafra Plant Manager. “We’ll continue to need an internal combustion engine to move those machines. For the time being, it will be in the form that we use today: the diesel engine. Synthetic fuels or hydrogen can considerably prolong their deployment.”

He points out that the income from this area finances DEUTZ’s investments in the green segment, which is dedicated to the mobility transformation. The 3.9-litre diesel engine is already set to run on gas or hydrogen in the future.

“Based on today’s design, this diesel engine can become a green engine in the long run,” says Industrialisation Manager Manuel Rodríguez López.

Such a possibility arrives via a package of small modifications, particularly to the cylinder head. However, the engine remains mostly the same otherwise. MAPAL is already collaborating on DEUTZ’s first hydrogen engine – a whopper at 7.8 litres.

Two weeks from design freeze to offer

“Our clients’ development periods for new parts are becoming shorter and shorter,” explains Thomas Spang, Global Head of Tool Management at MAPAL.

For tool manufacturers or complete suppliers like MAPAL, this reality represents a growing challenge – above all true if plans change at the last minute while the deadline for tool design remains the same. For the engine block of the new 3.9-litre diesel engine, MAPAL only had two weeks after the design freeze to complete a final offer.

An ardent team of experts at Mapal’s headquarters in Aalen, Germany, was able to complete this ambitious task on time. Well-tuned workflows proved advantageous for the team as did the many years of experience with the client’s production methods. MAPAL has been conducting tool management for DEUTZ in Spain for 18 years. Several projects have been completed together over the years.

MAPAL already engineered the machining of the engine blocks for the predecessor 3.6-litre diesel engine, which meant it was able to draw on practical experience and didn’t have to start from scratch. For example, MAPAL tool experts already knew which machines the engine manufacturer has from previous projects. DEUTZ has equipped its assembly line in Zafra with new five-axis machines over recent years, so it can switch to new products with relative ease.

When DEUTZ sent its request, the Tool Management department in collaboration with the Technology Expert Team (TET) in Aalen first gave some thought to the production process.

“To be quick, we don’t concern ourselves with detail at this early stage, but instead pull together reference tools and concepts from previously completed projects”, explains Harald Traub, Project Engineer from TET, who is responsible for planning the entire process. “In this way, we’re able to specify an approximate budget and the rough scope of the tool package for the client.”

One hundred different tools for an engine block

After this rough planning, concrete tool design followed in the second week. MAPAL’s offer for the series production of the motor block included almost 100 different tools. Many of them are custom tools that achieve short machining time and thus high economic efficiency. Aside from these, standard tools are used for milling.

To produce prototypes quickly, a few close-to-standard tools were also specified. Series production can then begin with the optimal set of tools. As part of their original delivery, MAPAL supplied DEUTZ with consumable tools, as well as the required tool holders and adapters. All other consumables will be handled by the tool management on site. From this point on, the client no longer pays per tool but per completed part. The unit costs at first correspond to the price determined during engineering. Certain ratios have been agreed upon for the following years. The client receives an increasing percentage of rebate and therefore pays a bit less per unit every year. For this business model to work out, MAPAL has to implement continual improvements to save costs. This is done with new tool technologies and corresponding optimisation. The costs per part are fixed over the term of the contract, after which a reassessment takes place. Such contracts, which run over four to five years, offer planning security to the client.

“With our engineering expertise, we support DEUTZ beyond the tool-setting area and cultivate a close partnership,” outlines Spang.

After helping to build the prototype, it’s the tool management’s turn to shine on-site during series production. DEUTZ uses approximately 1,300 different tools in total. Thousands of tools are available from stock and have to be managed at the Zafra facility. To keep inventory at an optimal level (avoiding bottlenecks while preventing unnecessarily high tool stocks), MAPAL uses its own warehouse management systems and digital solutions with c-Com cloud-based software for tool management. The digital Tool Management 4.0 doesn’t only handle procurement processes, which are initiated semi-automatically, it also acts as a reporting tool to analyse cost drivers and stocks.

Tools just-in-time for the assembly line

Manuel Rodríguez López praises the good collaboration with MAPAL when it comes to tool management: “Over the course of our co-operation, we’ve developed extensive technological concepts that go far beyond mere logistics. Besides achieving cost reductions, tool setting is particularly important for us. The MAPAL employees working on-site have a lot of know-how and ensure that production has exactly the tool they need at the right time.”

MAPAL’s tool manager on site is David Castaño. In Zafra, MAPAL also employs permanent tool setters who make sure that a dozen different parts are produced without a hitch.

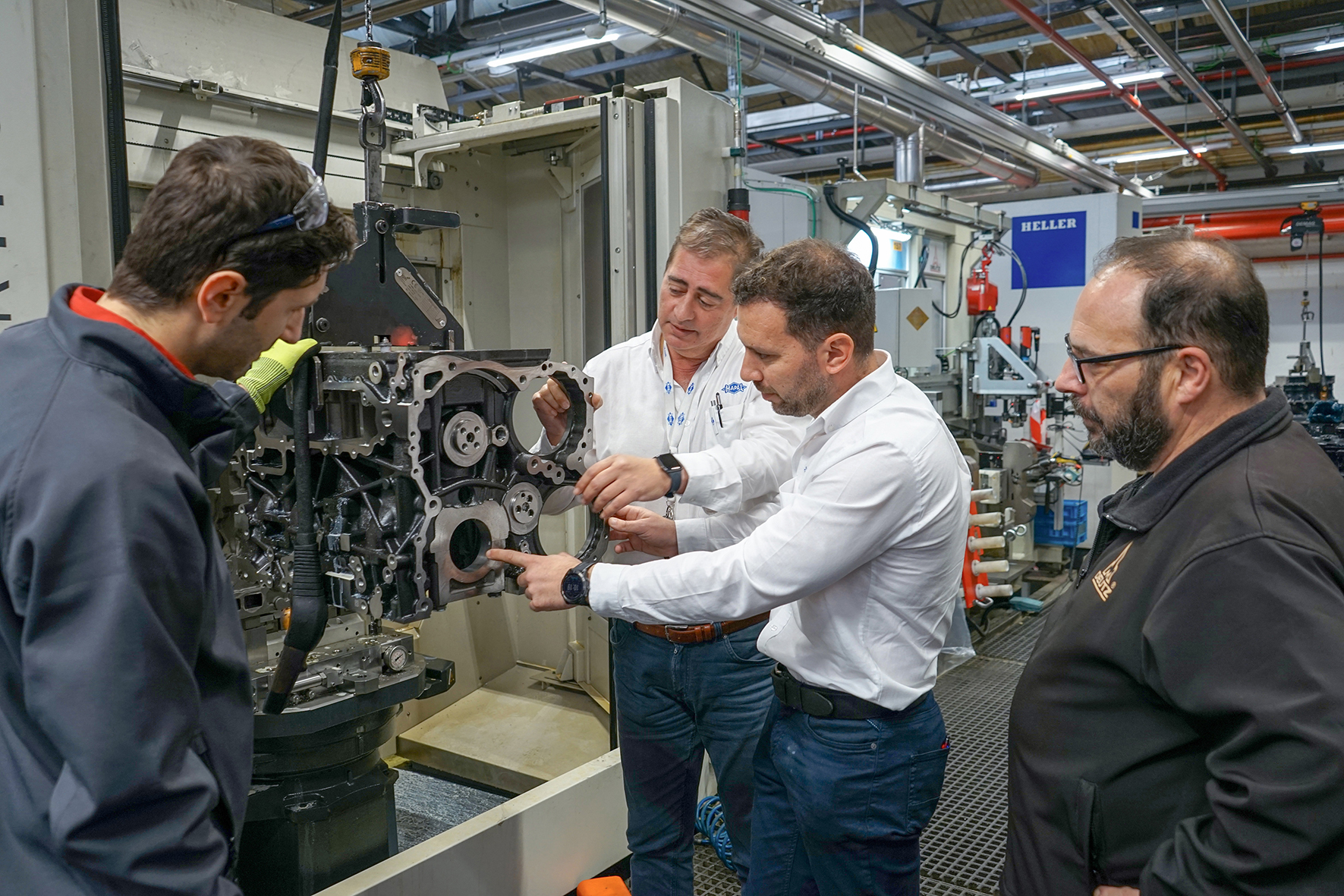

“It’s very beneficial to have David here on-site with us,” emphasises Manuel Padilla Fernández, Manufacturing Engineering Manager at DEUTZ, who works closely with the tool manager. “We can talk about any opportunities for optimisation directly at the machine. We don’t consider David Castaño to be an external service provider but rather a part of our team. It’s a very strong co-operation.”

Developing together to solve problems

If required, new tool solutions can be developed in Aalen via the local MAPAL team. That was the case in Zafra when it became necessary to optimise the tools for machining the bore in the crankshaft and camshaft. In co-operation with DEUTZ, a new machining concept from MAPAL based on its HPR400 reamer was implemented.

David Castaño is convinced of its advantages: “The tool life of the previous tool was 350 units and resetting was required every 100 units. With the HPR400, we achieve a tool life of 1,000 parts without resetting. The resulting machining quality is exceptionally good.”