Load faster, calculate faster and create backbores

The launch of hyperMILL® Release 2023 makes the CAD/CAM suite from OPEN MIND Technologies AG more powerful than ever before and introduces innovative functions. Not only does the software load faster, but the calculation time of tool paths has also been accelerated.

In addition, the ‘General Transformation Pattern’ function assures that users save time when machining recurring geometries. The new ‘back boring’ machining strategy attains the highest degree of convenience and safety via its use of VIRTUAL Machining technology.

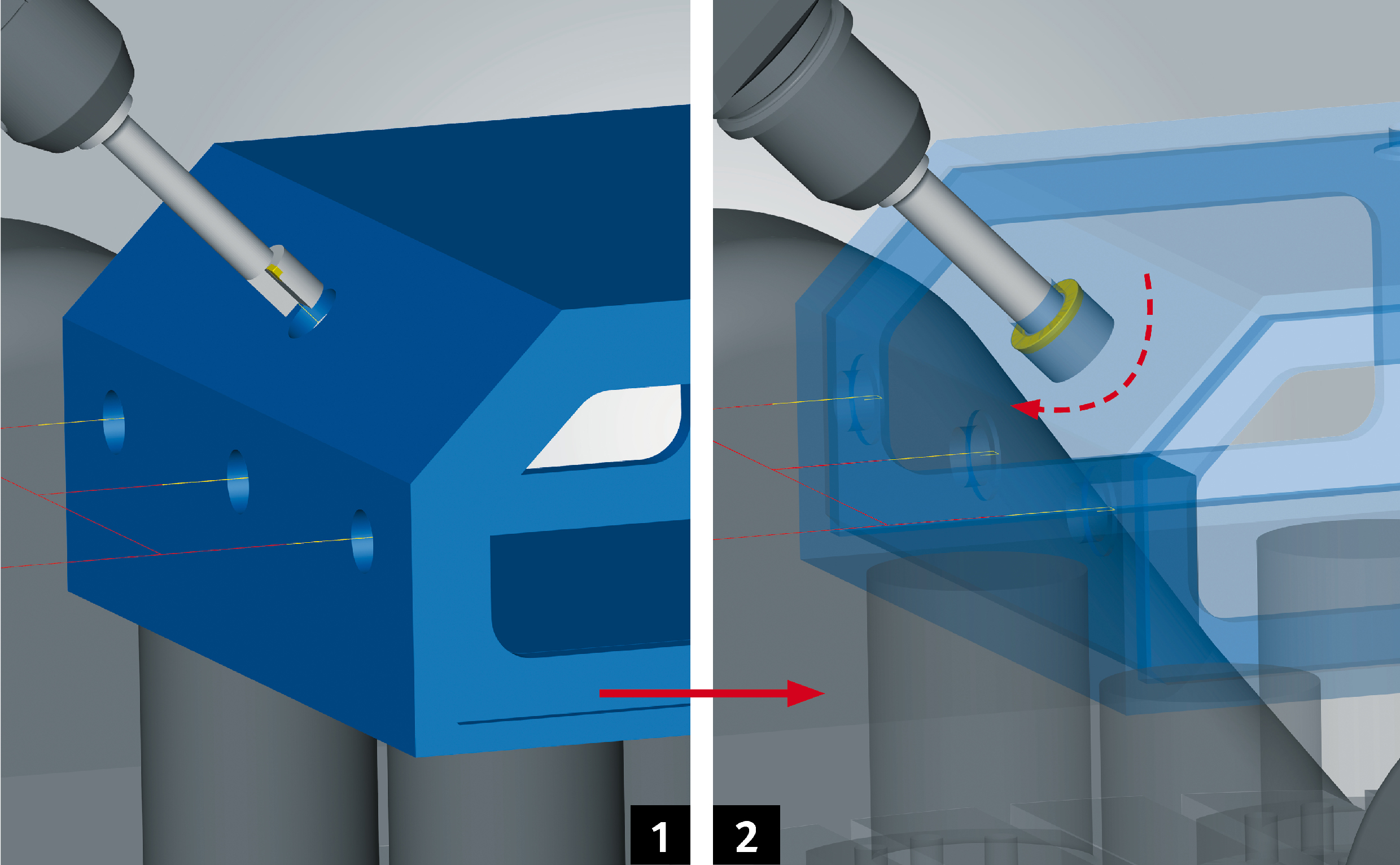

OPEN MIND has equipped the latest version hyperMILL® 2023 with a new machining strategy for back boring. Programming the tools used to deburr and mill a countersink on the inaccessible back side of a hole can now be done with incredible ease. This is credit to collision control that is conducted using a 3D model of the tool in the Virtual Machine. Therefore, potential damage that can be created when inserting and retracting tools is safely avoided.

Automatically transform any function

Up to now, standard features such as pockets and holes could be selected automatically. With the ‘General Transformation Pattern’ function, OPEN MIND now makes it possible to select any reference geometry and search for that same reference in all other models – regardless of its spatial orientation. This creates a general transformation pattern including a frame at each reference feature. This makes it easy to program recurring shapes with a single click. The function is also suitable for multiple setups.

5-axis strategy for more uniform surfaces

The arrival of the ‘5-axis Halfpipe Finishing’ strategy makes it incredibly convenient to program continuous toolpaths for grooves, tubes and halfpipes with any cross-section along an arched guide curve. This is a great advantage for users, as previously, this machining operation may have needed to be divided into several steps. This strategy opens a wide range of applications, especially in areas such as mould and die where the tool axis points in the de-moulding direction.

CAM in dialog

The example of back boring and its collision control based on a digital twin shows how hyperMILL® VIRTUAL Machining is already playing a role in standard functions. Simulation technology based on real NC and machine data is becoming increasingly important. OPEN MIND is driving the necessary communication between CAM system and machine controller forward at pace. Currently hyperMILL® VIRTUAL Machining supports CNC systems from HEIDENHAIN, SIEMENS, Mazak, FANUC, FIDIA, OKUMA, rödersTEC, D.ELECTRON, HURCO, and Haas with others set to follow.

CAD, CAM and data

hyperMILL® 2023 not only leverages advances in computing power and software engineering to increase performance, but it also streamlines processes. For example, the hyperMILL® SIMULATION Center loads faster. This is because it does not include unnecessary data for the calculation at hand. The optimised handling of data also provides improvement in other areas. hyperMILL® now makes it possible to import individual components from assemblies. Users can now use filters to select individual components when importing assemblies from other design systems’ native data. This reduces loading times for large assemblies and eliminates the need to subsequently delete individual parts that are not required.

Another new feature in hyperCAD®-ShyperCAD-S, the CAD part of the software suite tailored to CAM programmers’ needs, is the revision of the ‘Holes’ function. A hole can be composed and parameterised from a library of hole fits, countersinks and hole ends via a dialogue, which includes a preview. To improve graphic clarity, threads can also be displayed if required.