Leader says take a ‘steady’ rest at EMO Milan

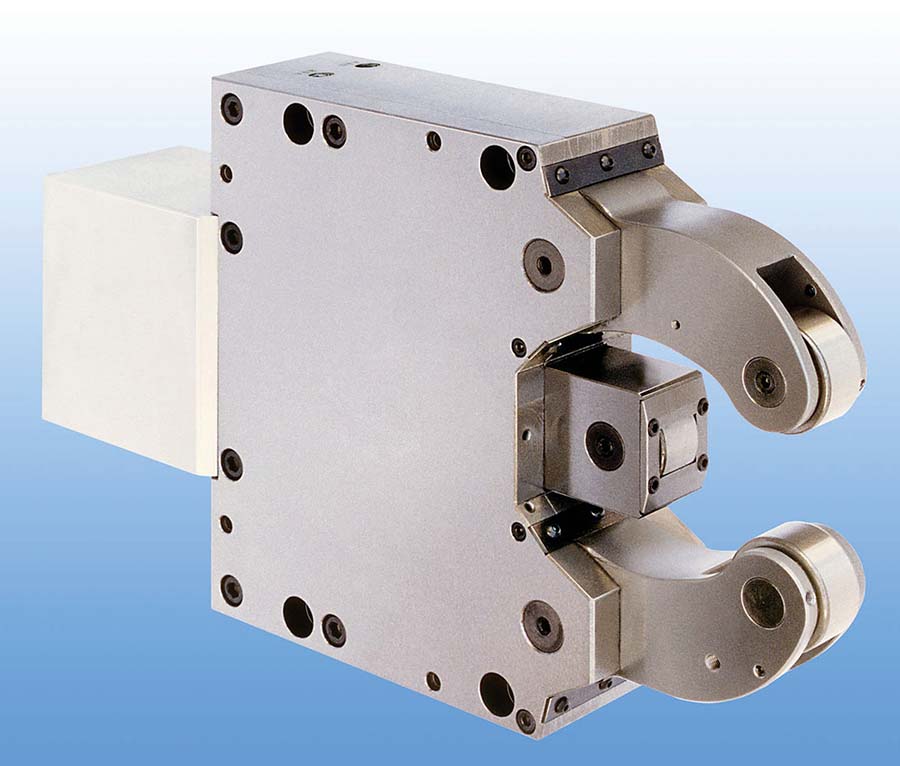

Exclusively represented in the UK and Eire by Leader Chuck International, Fabbrica Italiana Autocentranti Lombardia (FIAL) is an Italian ancillary equipment specialist with its core business focused on clamping equipment for lathes, both traditional and CNC. At this year’s EMO international machine tool exhibition, held in Milan on the 4 to 9 October 2021, on Stand F18 in Hall 3 the company will launch a number of new ranges of steady rests, including Self-Centring steady rests; the Coolant Series with feed for the steady rest’s rollers; a Mini Series for multi axis lathes and mill-turn centres and a range of high accuracy steady rests for grinding applications.

Leader Chuck International’s Managing Director, Mark Jones, explains: “The function of a steady rest is to stabilise workpieces as they are being rotated. As the workpiece turns, the jaws of the steady hold the centreline and the material being rotated never oscillates, wobbles or vibrates. This keeps the machining process precise, and you end up with a part that matches the design specification.”

The result of Leader FIAL’s ongoing research and development of innovative solutions, this extensive new range of steady rests includes 10 standard self-centring steady rests that cover the most popular sizes of material requirements while keeping the size of the unit to a minimum.

Without roller covers the steady rests increase incrementally to support workpiece or billet diameters from 4 – 70 mm up to an impressive 125 – 460 mm. When fitted with the automatically positioned roller covers the capacities drop slightly, starting at 15 – 62 mm diameter all the way up to 125 – 450 mm diameter. Heavy duty steadies are available up to 1000 mm capacity.

Even extremely heavy workpieces can be accommodated by the new steady rests, the smallest unit has an allowable load of 10 kg per roller and up to 450 kg per roller for the largest unit. Centring accuracy across the range is between 20 and 60 micron, with repeatability between +/- 5 and 10 micron.

For machine tools where space is limited, Leader FIAL offers the same sizes and technical benefits in a range of self-centring steady rests equipped with side cylinders. This range starts at 8 – 105 mm diameter capacity and extends to the same maximum size as the inline cylinder design.

Coolant Series

Providing extended protection for both the rollers and the workpiece is the Coolant Series of steady rests. With the addition of coolant fed through the arms via a special port, the working area around the rollers is kept clean thereby preventing damage to the rollers and the surface of the workpiece. Again, offering the same size and performance parameters as the standard range.

Mini Series

The Mini Series has been developed for highly efficient multi axis lathes where there is no option for the mounting of a steady rest, such as double turret turning centres. Here, the lower turret is used to mount the steady rest while the upper turret performs any operations required. These steady rests are designed to work on the popular bar fed smaller diameter raw material sizes, up to 65 mm diameter, and they are supplied with mounting systems that exactly match the machine tool used. Most popular mounting styles are supported, including front and radial VDI mounting shanks, Mazak perimeter sliding mounts, bolt-on face discs, Capto trilobe and EMAG tail systems.

High Accuracy

For external and internal cylindrical grinding applications, Leader FIAL will launch its High Accuracy steady rests. The four units in this application specific range provide support for parts of between 4 – 12 mm, 12 – 40 mm, 20 – 60 mm and 40 – 110 mm diameter.

Ensuring longevity each of the new steady rests benefit from a built-in central lubrication and pressurised air systems that have been designed to ensure the rollers operate correctly throughout the life of the unit. The rollers can be lubricated from the machine tool’s coolant system or with high flow grease while the positive air pressure, adjustable between 1 and 4 bar, keeps the working area clear of unwanted swarf and fines. Proximity detectors can signal confirmation that the device is fully open and ready to accept loading to the machine tool and/or loading ancillaries.

Mark Jones concludes: “When it comes to the turning process, FIAL has decades of experience. As well as this extensive range of new standard steady rests the company can also provide a bespoke service whereby units can be manufactured to suit customers’ exact specifications.”